This page describes how to operate xTool P2 with xTool Creative Space (XCS).

Minimum and recommended PC requirements

Item | Minimum configuration | Recommended configuration |

Processor | Intel Core i5-6200U | Intel Core i5-11600 |

Operating system | Win 10 (64-bit) macOS 10.14 or later | |

RAM | 8 GB | 16 GB |

Display resolution | 1280 × 720 (pixels) | 1920 × 1080 (pixels) or higher |

Hard drive | 8 GB | 12 GB |

- With the minimum configurations, all the functions of XCS can be used properly. When you import a complex image, such as an image larger than 50,000,000 pixels or an SVG image larger than 1 MB, however, XCS may fail to run smoothly.

- With the recommended configurations, XCS can run more smoothly when you import and edit a complex image, the software delay may be shorter, and the performance is better.

Download and install XCS

Click Yes when you are asked "Do you want to allow this app to make changes to your device?" and then continue the installation as prompted.

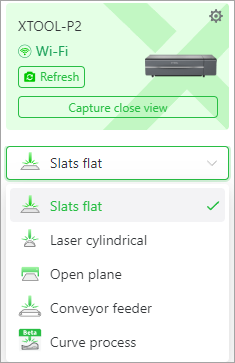

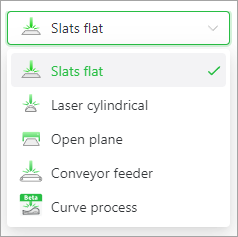

Processing modes

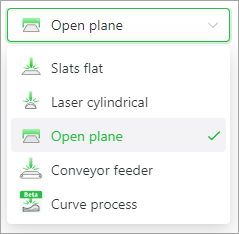

XCS supports multiple processing modes for xTool P2.

The processing modes are described as follows:

- Slats flat: to process flat materials with the slats in place

- Laser cylindrical: to process regular or irregular cylindrical materials

In this mode, you need to use xTool Rotary Attachment. For details about how to use xTool P2 with Rotary Attachment, see "Use xTool P2 with Rotary Attachment."

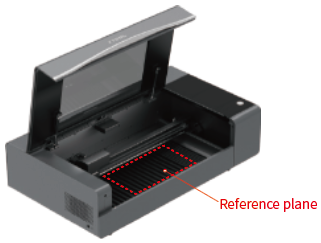

- Open plane: to process thick materials

In this mode, XCS allows you to place the material surface to be processed below the reference plane, that is, the plane formed by the upper sides of the slats.

- Conveyor feeder: to process long flat materials

In this mode, you need to use xTool Conveyor Feeder. For details about how to use xTool P2 with Conveyor Feeder, see "Use xTool P2 with Conveyor Feeder."

- Curve process: to process materials curved surfaces

Currently, this is a beta function and is being improved. In this mode, you need to remove all the slats and can measure a curved area on a material and map objects onto the area before processing the material. For details, see "Process Materials with Curved Surfaces Using xTool P2."

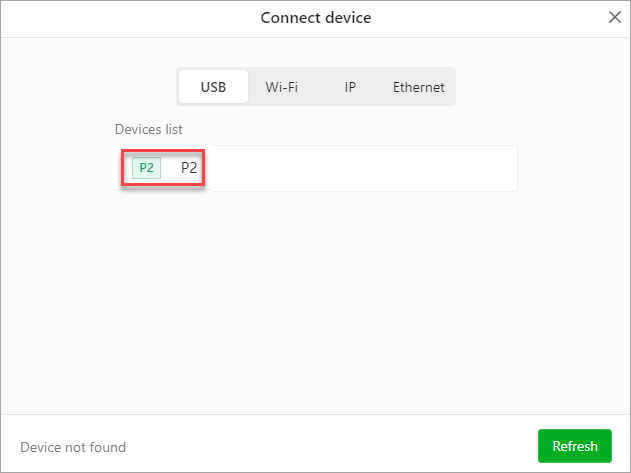

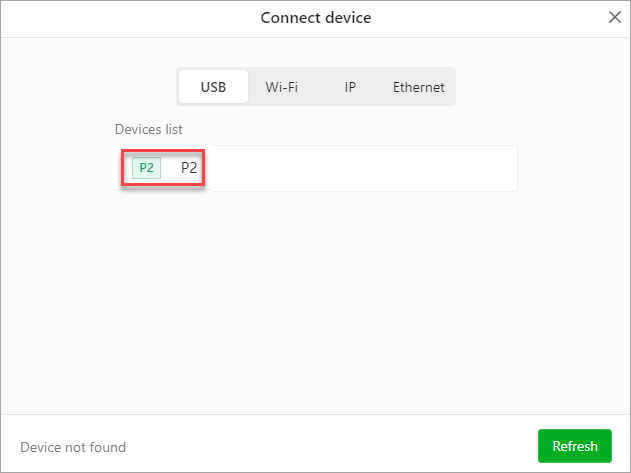

Connect a device

Note:

Whichever way you want to connect your device to the XCS client on your computer, you need to connect it to your computer with the USB cable first.

After you connect your device to XCS in Wi-Fi or IP mode, you can search for your device on XCS next time without USB connection.

USB connection

1. Use the USB cable to connect your device to your computer, and turn on your device.

2. Open XCS and click Connect Device.

Wait for XCS to search for available devices.

3. Select your device.

Wi-Fi connection

1. Use the USB cable to connect your device to your computer, and turn on your device.

2. Open XCS and click Connect Device.

Wait for XCS to search for available devices.

3. Select your device.

4. After the device is connected, click the device settings icon to open the device settings window. Click Settings under Wi-Fi setting.

5. Enter your Wi-Fi name and password as required to set up a Wi-Fi connection.

After you've connected your device through Wi-Fi, you can find it on the Wi-Fi tab.

IP Connection

You can enter the IP address of you device on XCS to connect it.

1. After connecting your device to XCS through a USB cable, find the IP address of the device in the device information and settings window.

2. Enter the IP address on the IP tab, and click Connect.

Example projects

You can start with a simple project. The following are some examples.

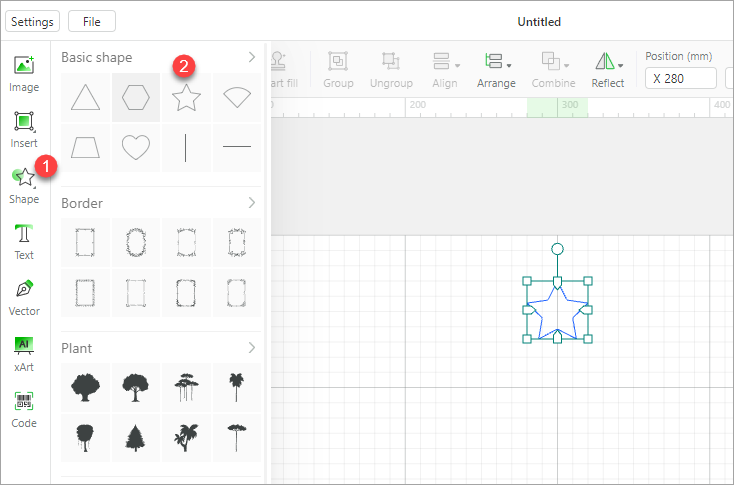

Engrave a star on a 3 mm basswood board

- Insert the star shape on the canvas.

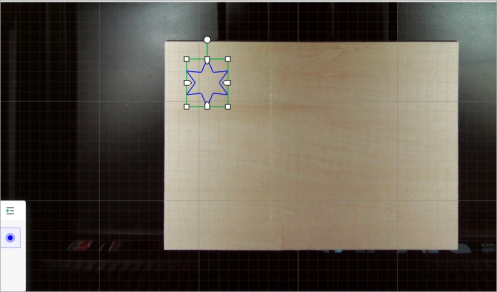

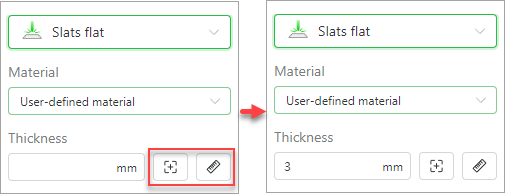

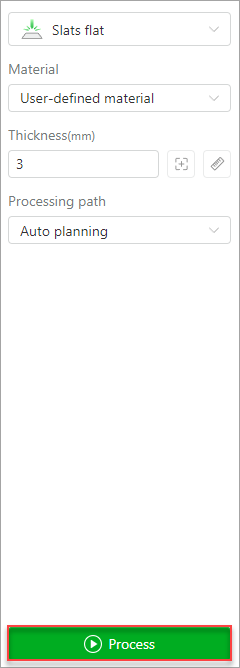

- Select the Slats flat processing mode.

- Place a basswood board on the slats, and move the object to the position where you want it to be processed.

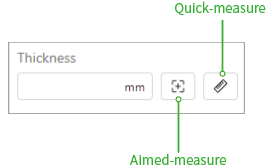

- Measure the thickness of the material. You can use either the aimed-measure or quick-measure to measure thickness.

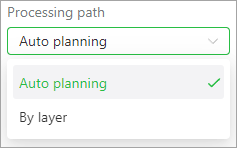

- Set the processing path. This project contains only one object. You can set the processing path to Auto planning.

- Set processing parameters for the object to be processed.

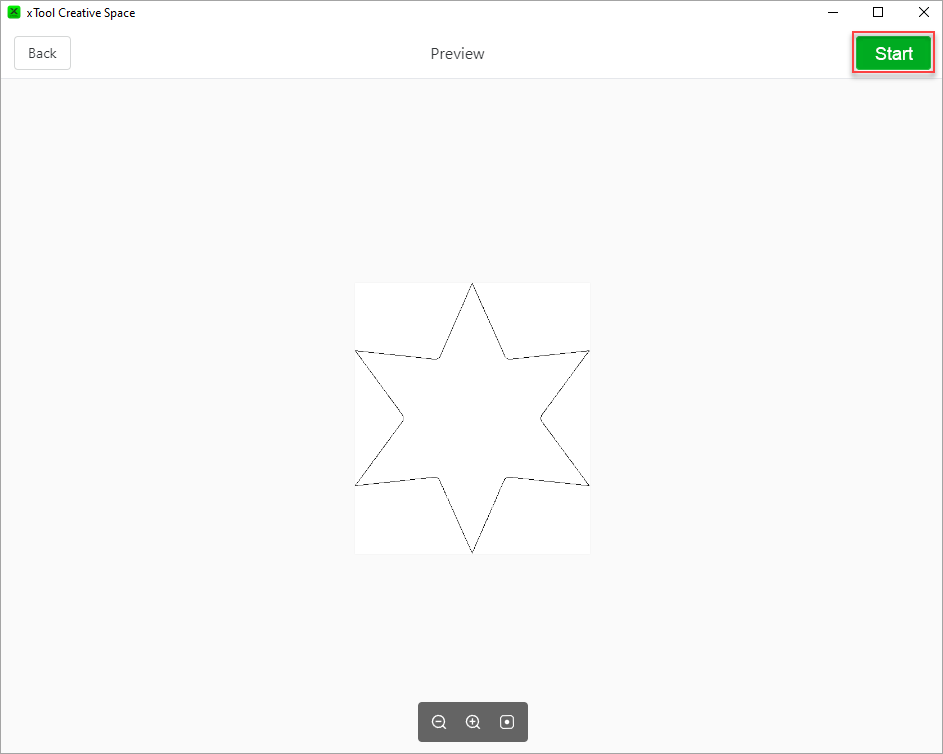

- Press the Process button.

- Preview the object and click Start.

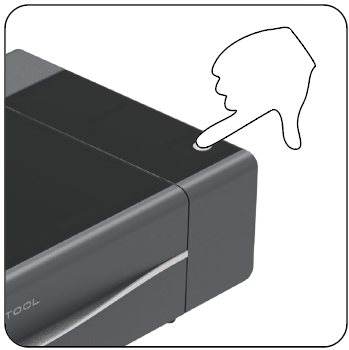

- Press the button on xTool P2 to start processing.

- Wait for the processing to complete.

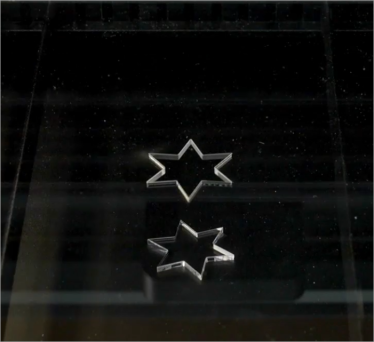

This is what you get after the processing.

Cut a star from an acrylic sheet

The steps for cutting a star from an acrylic sheet are similar to those of engraving a star on a basswood board.

- Insert the star shape on the canvas.

- Select the Slats flat processing mode.

- Place the acrylic sheet on the slats, and move the object to the position where you want it to be processed.

- Measure the thickness of the material.

- Set processing parameters for the object to be processed.

- Press the Process button.

- Preview the object and click Start.

- Press the button on xTool P2.

- Wait for the processing to complete.

This is what you get.

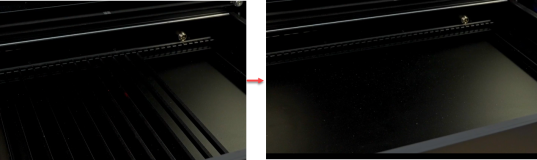

Engrave a pattern on a jewel case

- Measure the height of the jewel case.

The height is greater than 25 mm, you need to remove the slats.

- Remove the slats.

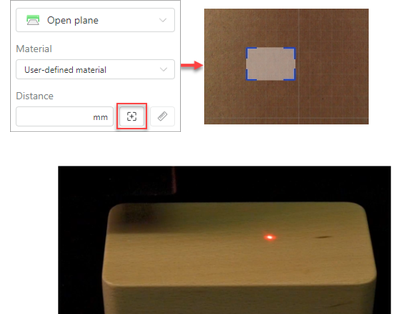

- Select the Open plane processing mode.

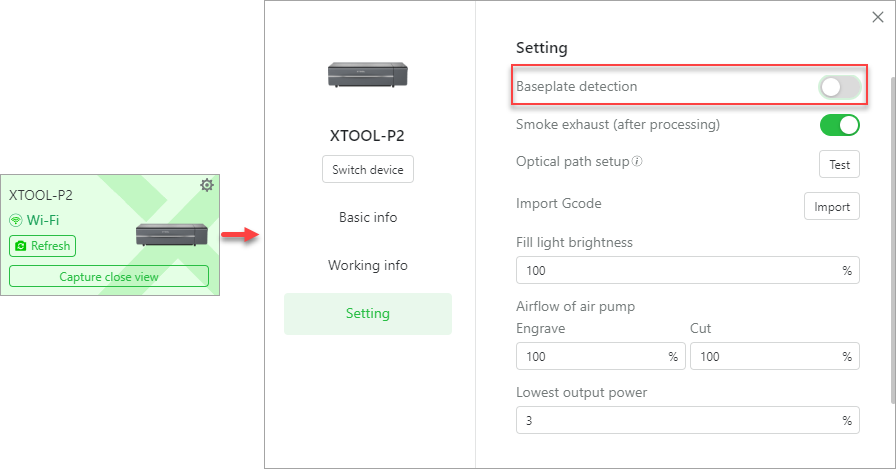

- Disable the baseplate detection function (required only for Class 4 xTool P2).

Note: By default, baseplate detection is enabled for xTool P2. For Class 4 laser machines, if you don't disable this function, XCS keeps prompting you to remove the baseplate in Open plane processing. For Class 1 laser machines, you don't need to disable it.

You can identify whether your machine is a Class 1 or Class 4 one based on the sticker on the back of the machine.

- Place the case in the working area, and click aimed-measure to allow the red spot to fall on the material.

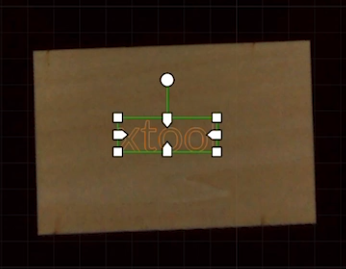

- Move the object to the position where you want it to be processed.

- Set the processing parameters for it.

- Press the Process button.

- Preview the object and click Start.

- Press the button on xTool P2.

- Wait for the processing to complete.

This is what you get.

With the rise base, conveyor feeder, and rotary attachment, xTool P2 can process thicker, longer, and a wider range of materials.

More examples

To process regular and irregular cylindrical materials, see "Use xTool P2 with Rotary Attachment."

To process long materials, see "Use xTool P2 with Conveyor Feeder."

Offline processing

When xTool P2 is in the idle state, that is, it is not processing a material, you can double press the button on the machine to start the last processing again. For offline processing, you don't need to connect xTool P2 to XCS.

XCS editor functions

You can use the XCS editor to design your own objects for processing. For details about the editor functions of XCS, see “xTool Creative Space (XCS) Editor Function Description.”

Device settings

View device information and set its functions

After connecting your machine to XCS, you can click the icons in the upper right corner to view the online help and device settings.

①: click to go to the online help for xTool P2

②: click to view the operating information of xTool P2 and set functions for it

Basic information

- Device name: sets the name of your device

- Laser model: displays the model of the laser module

- Laser safety classification: displays the laser safety classification of your machine, class 1 or class 4

- Serial number: displays the serial number of your device

- Plug-in version: displays the plug-in version of your device. You can click Info to view details about it.

- Firmware version: displays the firmware version of the device. You can click Check for updates to check for later versions and update the firmware.

- Wi-Fi setting: displays the IP address of your device. You can click Setting to enter the Wi-Fi name and password to set a Wi-Fi connection.

- Safety Terms: click to view the safety terms

Working information

- Working time: displays the total time the device processes materials

- Operating times: displays the total number of times the device has been operated

- Standby time: displays the total time the device is on standby

- Work log: You can click Export to export the work log of the device.

Setting

- Baseplate detection: enables or disables baseplate detection in processing preview. It is enabled by default. When it is disabled, no baseplate detection is performed in all the processing modes.

- Exhaust fan: enables or disables the built-in exhaust fan of your device.

- Exhaust time after processing: sets the time the exhaust fan continues to work after the processing is complete.

- Background brightness increase: increases the brightness of the background. When you are to process a dark-color or black material, you can enable this function to help you see the material more clearly. When you use a light-color or highly-reflective material, disable this function, or the background may be over-exposed.

- Buzzer: enables or disables the buzzer of the machine. After being disabled, the buzzer no longer works as an indicator.

- Optical path setup: allows you to test and modify the optical path. You can click Test to start testing the optical path. You can also click to view the detailed operation guide.

- Import Gcode: allows you to import a GCode file from the local disk. GCode files applicable to your device, exported on LightBurn, can be imported on XCS.

- Fill light brightness: sets the brightness of the fill light when the lid is opened.

- Setting range: 1–100

- The setting of a negative value does not take effect.

- Airflow of air pump:

- Engrave: sets the airflow for engraving. A lower airflow is recommended. Setting range: 30%–100%

- Cut: sets the airflow for cutting. A higher airflow is recommended. Setting range: 30%–100%

- Lowest output power: sets the lowest power input of the machine to ensure the optical output of the laser module. Theoretically, when the laser module produces laser beams properly, the output power is the same as the power input. As time goes by, however, the output power may be slightly lower than the power input. If your machine works properly, you don't need to set this parameter.

- Export elements on the canvas as GCode: exports all the elements on the canvas to a GCode file

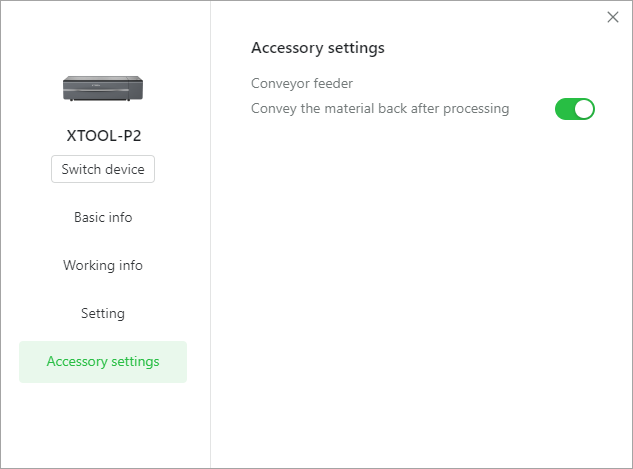

Accessory settings

- Convey the material back after processing: sets whether to convey the material back to its start position after processing it. This function is enabled by default, and you can click to disable it.

Processing settings

Note:

- If you use a material launched by xTool, you can select it from the material list and use the default parameter settings.

- If you use a material produced by another manufacturer, you can modify the parameters based on the settings recommended for xTool materials or your own tests.

Material settings

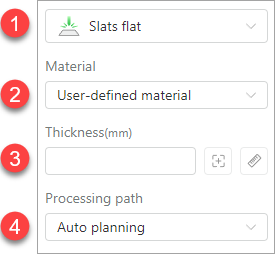

① Processing mode

You need to choose a processing mode based on your material.

The processing modes are described as follows:

- Slats flat: to process flat materials with the slats in place

- Laser cylindrical: to process regular or irregular cylindrical materials

In this mode, you need to use xTool Rotary Attachment. For details about how to use xTool P2 with Rotary Attachment, see "Use xTool P2 with Rotary Attachment."

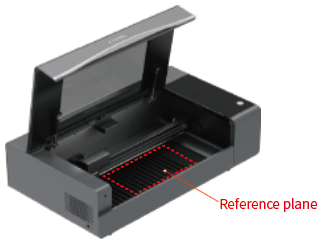

- Open plane: to process thick materials

In this mode, XCS allows you to place the material surface to be processed below the reference plane, that is, the plane formed by the upper sides of the slats.

- Conveyor feeder: to process long flat materials

In this mode, you need to use xTool Conveyor Feeder. For details about how to use xTool P2 with Conveyor Feeder, see "Use xTool P2 with Conveyor Feeder."

- Curve process: to process materials curved surfaces

Currently, this is a beta function and is being improved. In this mode, you need to remove all the slats and can measure a curved area on a material and map objects onto the area before processing the material. For details, see "Process Materials with Curved Surfaces Using xTool P2."

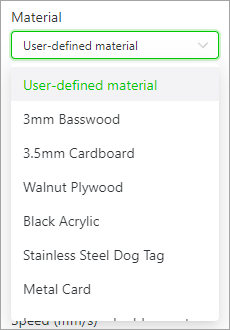

② Material

If you use a material launched by xTool, select your material from the drop-down list box. If you use one purchased from another manufacturer, set it to User-defined material, and set the processing parameters based on those recommended for xTool materials or your own tests.

③ Thickness / Distance

If you use a user-defined material, you can click Quick-measure to enable XCS to measure the thickness of the material. To measure the thickness of the material in a specified area, you can click Aimed-measure and select the area to be measured. If the automatic measurement fails, use a caliper to measure it and enter its thickness.

In some processing modes, such as Open plane and Flat cylindrical, you can see the parameter Distance, which means the distance between the upper surface of a material and the bottom of the laser module.

If auto-measure fails, you can measure the distance and enter it on XCS.

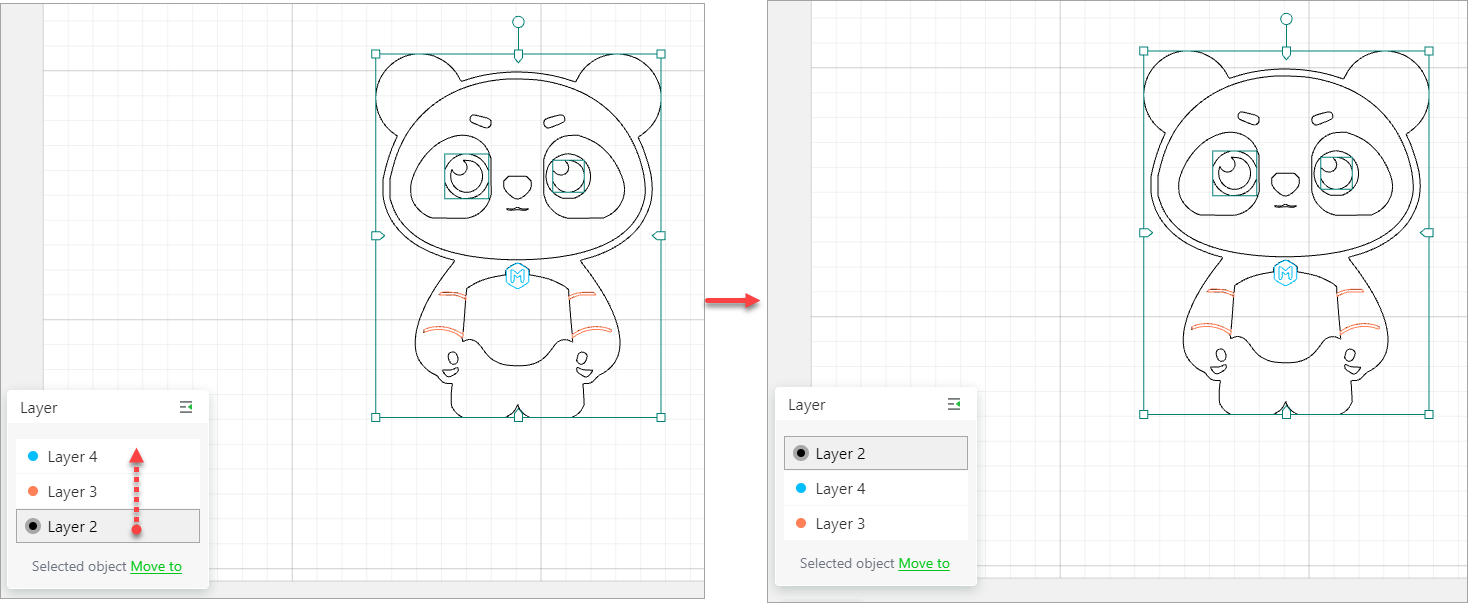

④ Processing path

You can set the processing path to auto planning or by layer.

Auto planning: Objects are processed based on the default processing path algorithm. Generally, objects are engraved first and then cut.

By layer: Objects are processed one layer by one layer, from top to bottom.

You can drag an object layer to move it up or down.

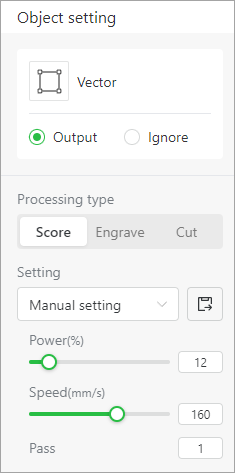

Object settings

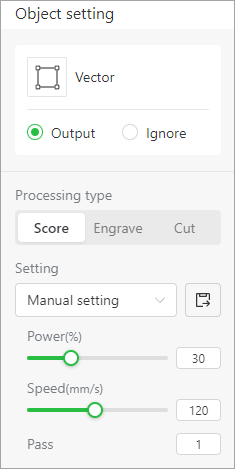

Vector settings

① Object type

Displays the type of the selected object, either vector or image

② Output or Ignore

Sets whether an element is to be processed

When you select an element and select Output, the element is to be processed. When you select Ignore, the element will not be processed.

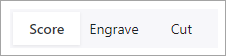

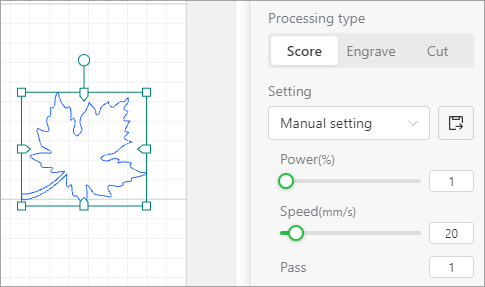

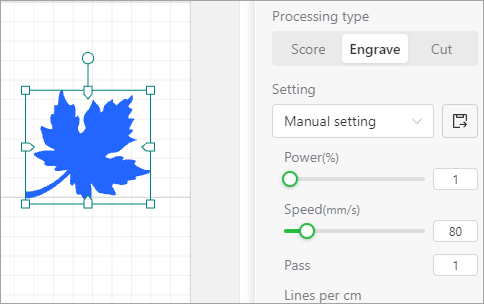

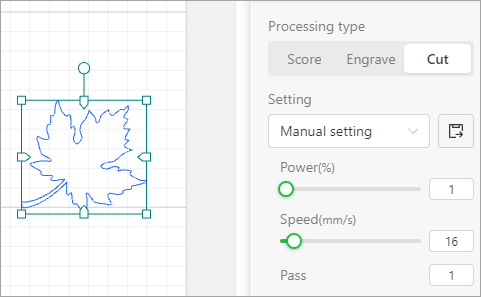

③ Processing type

Sets the processing type of the selected object

The processing types are described as follows:

- Score: engraves only the outline of an element

- Engrave: engraves the fill of an element

- Cut: cuts the outline of an element

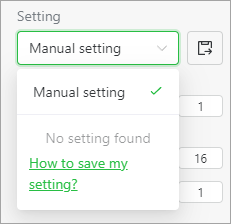

④ Setting selection

Selects a setting

A setting is a set of parameters (including power, speed, and pass) you've set. After you set the parameters, you can save them as a custom setting, and all the settings saved will be displayed in the Setting drop-down list box. When you select Manual setting, you need to set the parameters one by one. When you select a setting, the parameter values you saved before can be used.

⑤ Power

Sets the processing power

⑥ Speed

Sets the processing speed

⑦ Pass

Sets the number of processing times

⑧ Tab generation

Turns on or off tab generation

⑨ Generate

Sets the tab generation mode, by number or spacing

⑩ Number of tabs / Tab spacing

- Sets the number of tabs to be generated when you set the tabs to be generated by number. You can preview the tabs in the processing preview window,

- Sets the spacing between tabs when you set the tabs to be generated by spacing. You can preview the tabs in the processing preview window,

⑪ Tab size

Sets the size of a tab.

⑫ Tab cut power (%)

Sets the power for processing the tabs.

Bitmap settings

For bitmap processing, additional settings are provided.

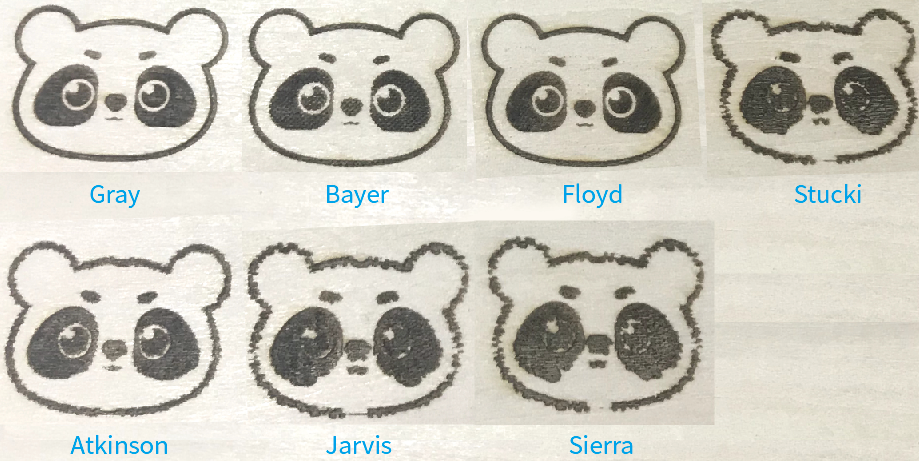

① Bitmap mode

XCS provides multiple bitmap modes, including Grayscale, Bayer, Floyd, Stucki, Atkinson, Jarvis, and Sierra. The default mode is Grayscale.

- Grayscale

Transforms an image into one of the shades of gray mode, in which a pixel is formed by a shade of gray that can be the darkest one (black), the brightest one (white), or one between them. The darker the pixel, the deeper the engraving.

- Bayer

Transforms an image into one in Bayer mode, which looks like adding a grid mosaic filter on the image.

- Floyd

Dithers an image by using the Floyd algorithm that diffuses the error only to the neighboring pixels, producing find-grained wave-like patterns on the image. It is recommended for highly-detailed images instead of those containing monotone swatches of color.

- Jarvis

Dithers an image by using the Jarvis algorithm that diffuses the error to 12 pixels around a pixel. Compared with Floyd, the transitions between pixels are slower, which produces a very nice looking pattern on almost all images.

- Stucki

Dithers an image in a similar way to Jarvis. Compared to Jarvis, the transitions between pixels are faster, which produces clean and sharp images.

- Sierra

Implemented based on the Jarvis algorithm, achieving a similar effect while producing sharper images.

- Atkinson

Dithers an image in a way similar to Jarvis and Sierra while producing sharper images. The Atkinson algorithm can preserve the details of an image well but the very dark or bright area may look disappeared.

With the other settings unchanged, the output of an image on a wooden board varies according to image mode, as shown in the following figure. You can select a mode as required.

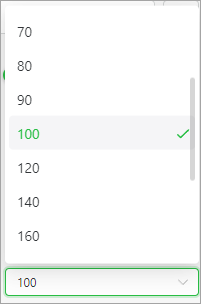

② Lines per cm

Sets the number of lines in one centimeter

This parameter determines the resolution of the image to be engraved.

③ Engraving mode

Sets the bi-directional or uni-directional engraving mode for bitmaps and filled vector paths

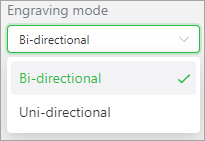

Start processing

(1) After setting the parameters, click Process.

The Preview window is displayed.

You can zoom in or out the object, or restore it to fit on screen during preview.

(2) Click Process in the upper right corner.

(3) Press the button on the device to start the processing.

You can also click Cancel to cancel the processing.

(4) Wait for the processing to complete.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.