Introduction

Safe operation of your xTool MetalFab CNC Cutter requires a well-trained Laser Safety Officer (LSO). To help you in complying with your LSO responsibilities and ensure that you operate xTool MetalFab CNC Cutter safely, xTool has consulted with laser experts to design the following LSO training materials.

The first document, LSO training for xTool MetalFab CNC Cutter, covers three sections:

- The first section, "Safe Operation of xTool MetalFab CNC Cutter", describes the procedures to ensure safe operation.

- The second section, "Laser Safety Officer Responsibilities", describes your role as the LSO for your xTool MetalFab CNC Cutter.

- The third section, "About Lasers and Laser Safety", describes general information about lasers and laser safety as well as regulations pertaining to lasers.

The second document, Laser Safety Program for xTool MetalFab CNC Cutter, is a laser safety program document that you, as the LSO for your xTool MetalFab CNC Cutter, may adopt.

The third document, Laser Standard Operating Procedure for xTool MetalFab CNC Cutter, offers a standard operating procedure (SOP) document for you to adopt, which is a part of the Laser Safety Program for xTool MetalFab CNC Cutter.

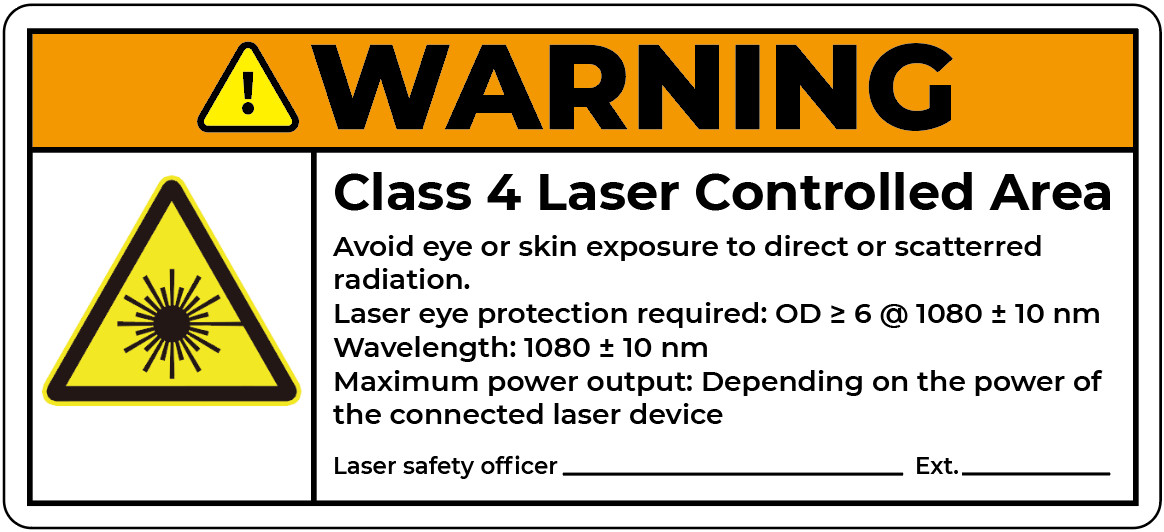

The fourth document, Warning Sign, offers signs you may choose to use as a compliance measure described in the SOP.

LSO training for xTool MetalFab CNC Cutter

Safe Operation of xTool MetalFab CNC Cutter

Class 4 Conditions

Your xTool MetalFab CNC Cutter is a Class 4 laser. Everyone who uses xTool MetalFab CNC Cutter must read and follow all instructions in the user manual and xTool software.

Protective lid

xTool MetalFab CNC Cutter comes with a protective lid. Diffused laser beams may leak out from the openings on the sides of xTool MetalFab CNC Cutter or those on the riser base, and you may be exposed to laser radiation greater than Class 1. Therefore, the fully assembled machine of xTool MetalFab Laser Welder and xTool MetalFab CNC Cutter is intended for professional use only, and extra care should be taken during use to ensure safe operation. Children and untrained users should be forbidden from accessing xTool MetalFab CNC Cutter.

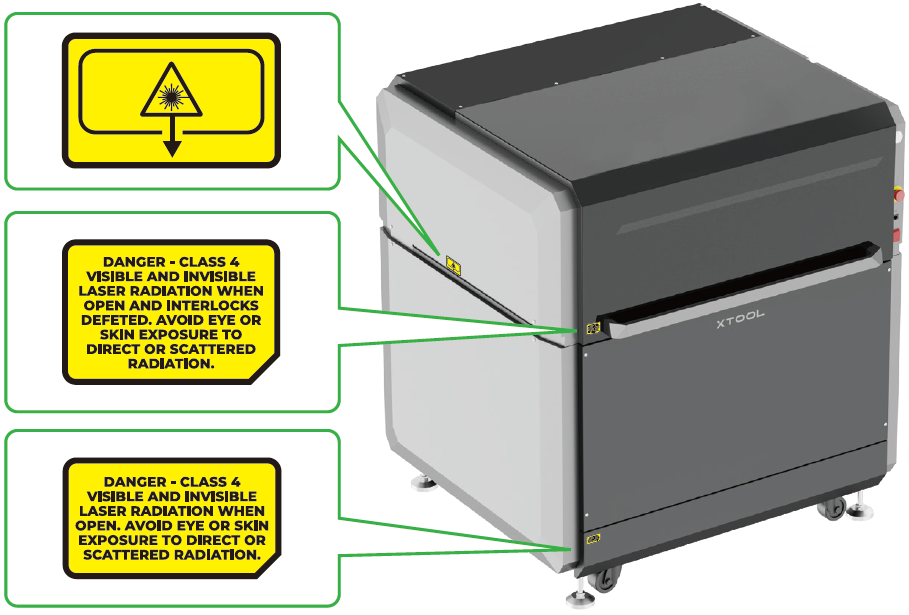

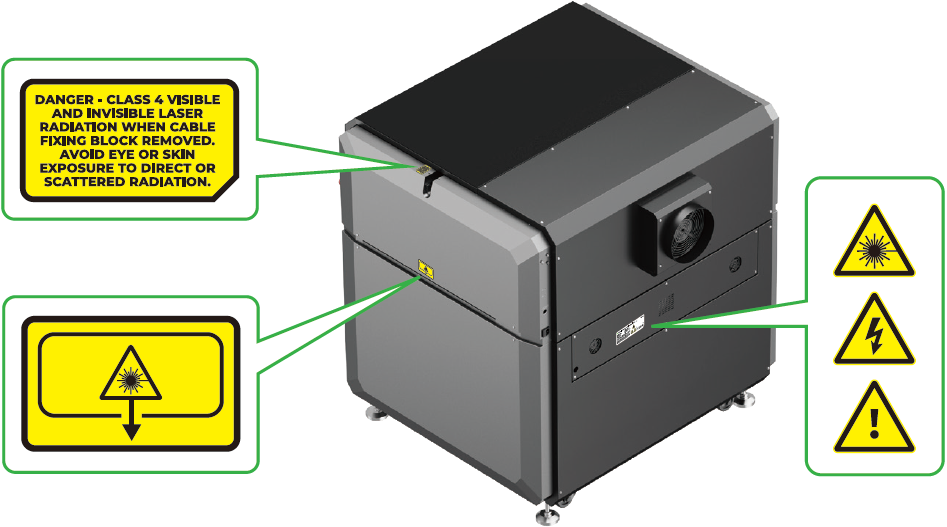

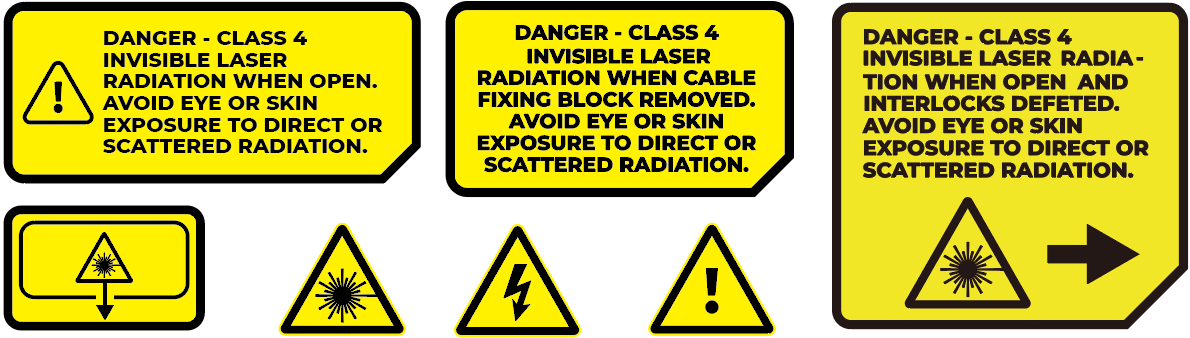

Sign

On the product, the warning and instruction signs are labeled where physical injuries or damage to the product may be caused before and/or during operation. If a sign is damaged or lost, replace it immediately. You can use the following template to print the sign you need.

Operations under Class 4 conditions

Operations under Class 4 conditions

When xTool MetalFab CNC Cutter is under use, you are responsible for ensuring safe operation. The provided SOP does not permit safe operation in Class 4 conditions, so the LSO must create an SOP that does. Ultimately, the LSO is responsible for defining the content of the SOP and describing and implementing the SOP, and the laser operator is responsible for ensuring compliance and safe operation. Some key elements of a Class 4 SOP may include:

Appropriate safety goggles

xTool MetalFab CNC Cutter does not provide safety goggles. You can purchase safety goggles at xtool.com. All personnel entering the laser controlled area must wear laser safety goggles that provide shielding against laser beams at the wavelength range of 1080 ± 10 nm, with an optical density greater than 6. Note that these safety goggles protect only against the diffuse reflection of the laser, so be careful to avoid direct laser light.

Laser signs

An appropriate laser safety sign is placed at the entryway to alert people to the hazards inside. A sample sign is shown below.

Light and visual indication

Set up a light outside the door that the user can switch on before beginning to use the laser to indicate that the laser is in use. A battery-powered LED light may be used.

Emergency stop button

xTool MetalFab CNC Cutter is equipped with an emergency stop button. When the emergency stop button is pressed, the device will be shut off.

Laser Safety Officer Responsibilities

The LSO and Your Laser Safety Program

ANSI Z136.1-2022 sets recommended guidelines for the safe use of lasers that operate at wavelengths between 180 nm and 1000 μm. Primary safety responsibility rests with someone designated as the Laser Safety officer, or LSO. This document is designed to assist you in acting as the LSO for one or more xTool MetalFab CNC Cutter units. It does not provide sufficient information to advise you in acting as the LSO for any other laser.

The LSO verifies the classification of the laser. The LSO determines the level of hazard by considering the details of the laser, and creates a standard operating procedure (SOP) that determines what control measures (like additional interlocks, training, and safety goggles) should be used.

The LSO is then responsible for helping and training other laser users, ensuring safe compliance, analyzing any possible hazards, providing safety equipment, ensuring all regulations are complied with including (in the US) CDRH, OSHA, and state regulations, and auditing the use of the laser to make sure it's used safely.

Beyond these responsibilities, the LSO must also recommend and approve signs, labels, protective equipment, facilities, equipment, any modifications, maintain records, approve laser system operation, and investigate accidents should one occur. The LSO is ultimately the one responsible for determining if and how a laser may be safely operated.

Hazard Analysis

The LSO must analyze the hazards present in the lasers for which they are responsible. The LSO may rely on an expert for the execution of hazard analysis. xTool created a hazard analysis (provided below) of the xTool MetalFab CNC Cutter that you may choose to use in your laser safety program.

Standard Operating Procedure

Based on Hazard Analysis, the LSO must create a standard operating procedure (SOP) that describes the control measures required to minimize hazards. xTool has also created a sample SOP (provided below) that you may use or adopt to your xTool S1 laser safety program.

About Lasers and Laser Safety

How Lasers Are Different

Lasers are a special kind of light source. Most light is made of many different colors, all shining out in lots of directions at once. Laser light is different in three ways.

First, laser light is monochromatic—just one color. Sometimes that color is visible, like the low-power red laser that you can see your xTool machine use to measure material when it's focusing. Sometimes it's invisible, like the high-power infrared laser beam your xTool machine uses to cut materials.

In technical discussions, people describe lasers as producing "nonionizing electromagnetic radiation". That describes a broad category that includes everything from sunshine to radio waves. Instead of talking about color, they use the term "wavelength". The laser wavelength used by your xTool MetalFab CNC Cutter depends on the connected laser device.

The second difference between laser light and regular light is that laser light is directional. That means that it can be made to travel in a straight line, in a beam, without spreading out much.

The third difference is that laser light is coherent. That means that each lightwave is synchronized with the others.

It's very hard to get light to move in a straight line, without spreading out. If the waves aren't lined up, or if there's a mix of colors and directions, the beam will spread out. Lasers, however, can stay lined up for a long distance—and, importantly, can be focused down to a point.

Lasers' greatest effectiveness—and danger—as compared to ordinary light comes from lasers ability to be focused.

Laser Background

The very first laser used a strobe light and a ruby crystal. The light from the strobe was amplified in the ruby crystal, stimulating it to emit nonionizing electromagnetic radiation at 694 nanometers. The acronym "LASER" comes from this experiment—light amplification through stimulated emission of radiation.

These first lasers were called "solid-state" lasers because the action parts were solid crystals. Shortly after the development of solid-state lasers came gas lasers, which can resemble neon signs. Electricity causes gas in a tube to glow. Specially tuned mirrors amplify the light, and the laser beam emerges.

Measurements

There are four measurements used to describe the effect of a laser.

Joules measure energy. If you shine a light on a gram of water until it absorbs 1 joule of energy, the water will heat by about a quarter of a degree Celsius.

Watts measure power. If you turn on a one-watt light for a second, it will put out 1 joule during that time.

Joules per square centimeter measure radiant exposure. If you focus down that one-watt light to a square centimeter of paper and shine it for a second, that one joule will spread over the paper, and it will heat up slightly, just like the water. However, if you focus it down to 1/100th the size, the paper may singe and turn brown.

Finally, watts per square centimeter measure irradiance. If you keep shining that one-watt light on the paper, it will keep adding joules of energy. If it's focused to one square centimeter, it will slowly warm. If it's focused to 1/100th the size, the paper may catch fire.

Laser Beam Hazards

Laser beams can be hazardous because the energy of the laser can damage the eyes and skin. This can cause damage to both eyes and skin. The risk is higher if the laser is more powerful if it is more focused, and if it stays in one place for a longer time, so all of these factors are considered when assessing safety.

The laser beam can strike a person in one of three ways. First, the laser can be pointed at the person directly. Second, in specular reflection, the laser can be reflected toward a person. Third, in diffuse reflection, the laser strikes a surface that is not a mirror and scatters the light in all directions. Because the light from a diffuse reflection is scattered, it is not as hazardous as direct or reflected light, but there may still be enough intensity to cause damage.

Laser Hazard Classes

Lasers are classified by the level of radiation that may be encountered during normal operation.

Class 1 lasers are incapable of causing injury during normal operation. Class 1M lasers are the same, except unless magnifying optics are used.

Class 2 lasers are incapable of causing injury in less than 0.25 seconds. Class 2M lasers are the same, except unless magnifying optics are used.

Class 3R lasers are marginally unsafe if the beam is directed at the eye. Class 3B lasers are hazardous if the beam is directed at the eye, but are usually not an eye hazard if the beam is scattered.

Class 4 lasers are eye and skin hazards for both direct and scattered exposure. xTool MetalFab CNC Cutter is a Class 4 laser.

Laser Regulations

In the US, laser manufacturers like xTool are regulated by the Center for Devices and Radiological Health (CDRH) and are required to follow 21 CFR 1040.10 and 1040.11, which are federal laws. In many other countries (but not the US), both laser manufacturers and laser users are required to follow IEC60825.

ANSI Z136.1 is a voluntary standard that describes how to use lasers safely. OSHA (a US federal law that applies to workplaces but not to private homes) requires a safety program like that described in the ANSI standard.

The CDRH requires that Class 4 laser devices have a defined set of safety features. The protective lid of the xTool MetalFab CNC Cutter prevents access to excess laser radiation and serves as protective housing. Safety interlocks disable the laser if the lid is opened. The key included in the package of xTool MetalFab Laser Welder serves as both an access-control key and a remote interlock connector. Removing the key can disables the machine's processing and related functions. The annular indicator of xTool MetalFab CNC Cutter indicates the device state. The controls are located so that laser exposure is not required to operate them. There are also certain labels present required by US and some international laws.

There may be other laser regulations depending on your country, state, and even city, and regulations may change. This information is provided to assist you in creating a safety program as described by ANSI Z136.1, but cannot advise you on legal compliance.

Non-Beam Hazards

There are additional hazards to your xTool MetalFab CNC Cutter. Always operate your xTool MetalFab CNC Cutter following all instructions in user manuals and xTool software to minimize hazards.

Laser Generated Air Contaminants

When using a laser to process materials, a variety of air contaminants may be produced that can be hazardous. The air must be filtered to remove those contaminants. Follow the user manual of xTool MetalFab CNC Cutter to ensure that all exhaust is either properly treated or discharged outdoors where it can safely dissipate.

Process Nonionizing Radiation

Processing metals with a laser may result in the release of ultraviolet light. If your xTool MetalFab CNC Cutter produces a bright light that cannot be viewed comfortably, look away.

Collateral Nonionizing Radiation

The material that produces the laser beam may emit harmful levels of UV and/or IR light. xTool MetalFab CNC Cutter has been tested to ensure that harmful levels are not present outside the lid or when viewed through the lid (PC+ABS).

Laser Safety Program for xTool MetalFab CNC Cutter

Scope

This program applies to xTool MetalFab CNC Cutter Laser operated by xTool MetalFab CNC Cutter Owner. This program is based on the guidance of ANSI Z136.1-2014, the American National Standard for Safe Use of Lasers. The proper implementation of this program will assure that laser exposures are always below the maximum permissible exposure (MPE) limits.

Laser Safety Officer

An individual designated as the Laser Safety Officer (LSO) shall have the responsibility and authority to assure compliance with this program. The LSO shall:

- Provide hazard evaluations for xTool MetalFab CNC Cutter laser

- Specify control measures for the xTool MetalFab CNC Cutter laser and assure implementation

- Approve procedures, SOPs, protective equipment, signs and labels

- Assure that all laser personnel receive appropriate safety training

- Monitor the program and assure compliance

- Maintain program records

The LSO shall have final authority in determining xTool MetalFab CNC Cutter laser control measures and may approve alternate controls when these are appropriate based on the judgment of the LSO. xTool MetalFab CNC Cutter laser shall be operated only with the approval of the LSO. The LSO shall have the authority to terminate laser operations at any time.

Laser Classes

Class 1 laser systems are incapable of producing damaging radiation levels during normal operation and are exempt from any control measures. Class 1 laser systems may contain higher class lasers and may produce laser hazards if operated with interlocks defeated. Only authorized personnel may operate Class 1 laser systems with interlocks defeated. Operators of Class 1 laser systems with embedded Class 3B or Class 4 lasers shall receive a laser safety briefing.

Class 1M laser systems are incapable of producing hazardous exposure conditions during normal operation unless the beam is viewed with optical instruments. Operators of Class 1M laser systems shall receive a laser safety briefing.

Class 2 laser systems emit visible light only at a power level of 1 milliwatt or less. The normal aversion response to bright light is adequate protection. Staring into the beam of a Class 2 laser is hazardous. Operators of Class 2 laser systems shall receive a laser safety briefing.

Class 2M laser systems emit visible light only. The normal aversion response to bright light is adequate protection for unaided viewing. However, viewing the beam with optical aids is potentially hazardous. Operators of Class 2M laser systems shall receive a laser safety briefing.

Class 3R laser systems are potentially hazardous under some viewing conditions, but the probability of an actual injury is small, and the control measures for safe use are straightforward. Most laser pointers fall in this class. Operators of Class 3R laser systems shall receive a laser safety briefing. (Most lasers previously classified as Class 3A fall in this category.)

Class 3B laser systems are eye hazards for intrabeam viewing and specular reflections, even for momentary exposures, but diffuse reflections are not usually hazardous. Class 3B laser systems shall be operated only in laser-controlled areas by authorized operators. Operators of Class 3B laser systems shall receive approved laser safety training.

Class 4 laser systems are eye hazards and skin hazards for intrabeam exposures, specular reflections, and diffuse reflections. They are also fire hazards and may produce laser-generated air contaminants. Class 4 laser systems shall be operated only in laser controlled areas by authorized operators. Operators of Class 4 laser systems shall receive approved laser safety training. Written SOP is required for Class 4 laser operation. Written Standard Operating Procedures (SOP) are required for Class 4 laser operation. xTool MetalFab CNC Cutter is classified by IEC 60825-1:2014 as a Class 4 laser system.

Training Requirements

When operating in Class 4 conditions, additional laser safety training is required and must be prepared and administered by the LSO.

Do not use the product in public places, or on other occasions where untrained persons or children are present.

Control Measures

The requirements for the xTool MetalFab CNC Cutter Laser controlled area shall be determined by the LSO. The minimum requirements considered by the LSO for the xTool MetalFab CNC Cutter Laser controlled area are:

If needed entryway controls to allow only authorized personnel or approved spectators to enter the xTool MetalFab CNC Cutter Laser control area. (Administrative controls are acceptable.)

Laser safety eyewear available and used in accordance with the SOP for the xTool MetalFab CNC Cutter Laser.

Beam control (barriers and beam blocks) to limit laser hazards within the controlled area.

Written SOP for the xTool MetalFab CNC Cutter Laser.

Training of the xTool MetalFab CNC Cutter Laser operators.

Eyewear Policy

The LSO will require eyewear or approve laser operation without eyewear based on a hazard evaluation performed by the LSO or the LSO may choose to delegate this responsibility.

Responsibilities of employees working with lasers

Employees who work with the xTool MetalFab CNC Cutter Laser with the beam exposed shall:

Energize or work with lasers only when authorized to do so.

Comply with laser safety rules and work procedures.

Notify their supervisor or the LSO in case of potential accident or injury or suspected unsafe condition.

Laser safety audit

At an interval determined by the LSO, the xTool MetalFab CNC Cutter Laser will be audited for safety:

It will be visually inspected for damage.

The most recent user version of the manual will be re-read.

The laser will be powered on and self-checked to confirm whether the safety settings are invalid.

The Laser Safety Program will be reviewed to ensure that the program is current and compliant.

A record of this audit will be completed, printed, signed, dated, and retained.

Records

The LSO shall maintain records that document the Laser Safety Program. These records shall include:

- Laser hazard analysis reports for xTool MetalFab CNC Cutter Laser

- A list of operators who have been trained and permitted to use xTool MetalFab CNC Cutter Laser

- Standard Operating Procedures for xTool MetalFab CNC Cutter Laser

- Approvals of alternate laser control measures, if implemented

- Laser Safety Audit checklist

Laser Standard Operating Procedure (SOP) for xTool MetalFab CNC Cutter

Wavelength | Beam divergence (near field) | Maximum power output | |

Working laser | 1080 ± 10 nm | -0.1 mrad to + 0.2 mrad | Depending on the power of the connected laser device |

Indicator laser | 660 ± 10 nm | -0.1 mrad to + 0.2 mrad | 0.39 mW |

Potential Hazards

A. Eye hazard from the direct, reflected, or scattered beam.

B. Skin hazard and fire hazard.

C. Electrical hazard inside the power supply.

D. Laser Generated Air Contaminants.

Control Measures

A. The LSO will only allow physical access to the laser to users who have been enrolled in the xTool software and thereby receive safe operating instructions.

B. All users of the xTool MetalFab CNC Cutter Laser will follow the user manual and all instructions in the xTool software at all times.

C. Do not operate xTool MetalFab CNC Cutter with bystanders and children nearby, or in public places where the protective lid is not used safely. You can take away the key to ensure that your xTool MetalFab CNC Cutter will not be used by others.

D. Keep all combustibles, tools, and reflective surfaces away from the beam path. Make sure you know where the beam is and stay clear.

E. Work involving access to the power supply shall be done by the manufacturer with no exceptions.

F. Maintenance shall be done with the laser system turned off.

Required Training: When operating in Class 4 conditions, additional laser safety training is required and must be prepared and administered.

For emergency medical response call____. Report all incidents to the LSO.

Authorized Personnel

The following personnel are authorized to operate this system:

By reading this LSO document, you will be considered to be qualified or authorized.

Warning Sign

Disclaimer:

This training document is based on existing searchable documents, including but not limited to 21 CFR Part 1040.10, 1040.11, ANSI Z136.1 Standard—Guidance for Implementing a Safe Laser Program, OSHA, the U.S. Occupational Safety and Health Alliance, the U.S. Laser Protocol: the Laser Regulators and the Center for Devices and Radiological Health, and other publicly available documents and standards issued by the above agencies at the time of this document's development. The documents and standards issued by these organizations and available in the public domain have been prepared, and the courses and presentations of some laser safety experts in the public domain have also been taken into account. The final right of interpretation of this document belongs to xTool.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.