xTool Studio Desktop V1.4.10 Release Notes

Version: Desktop V1.4.10

Date: January 26th, 2026

Download link:

Windows Version macOS-Intel Version macOS-M Version

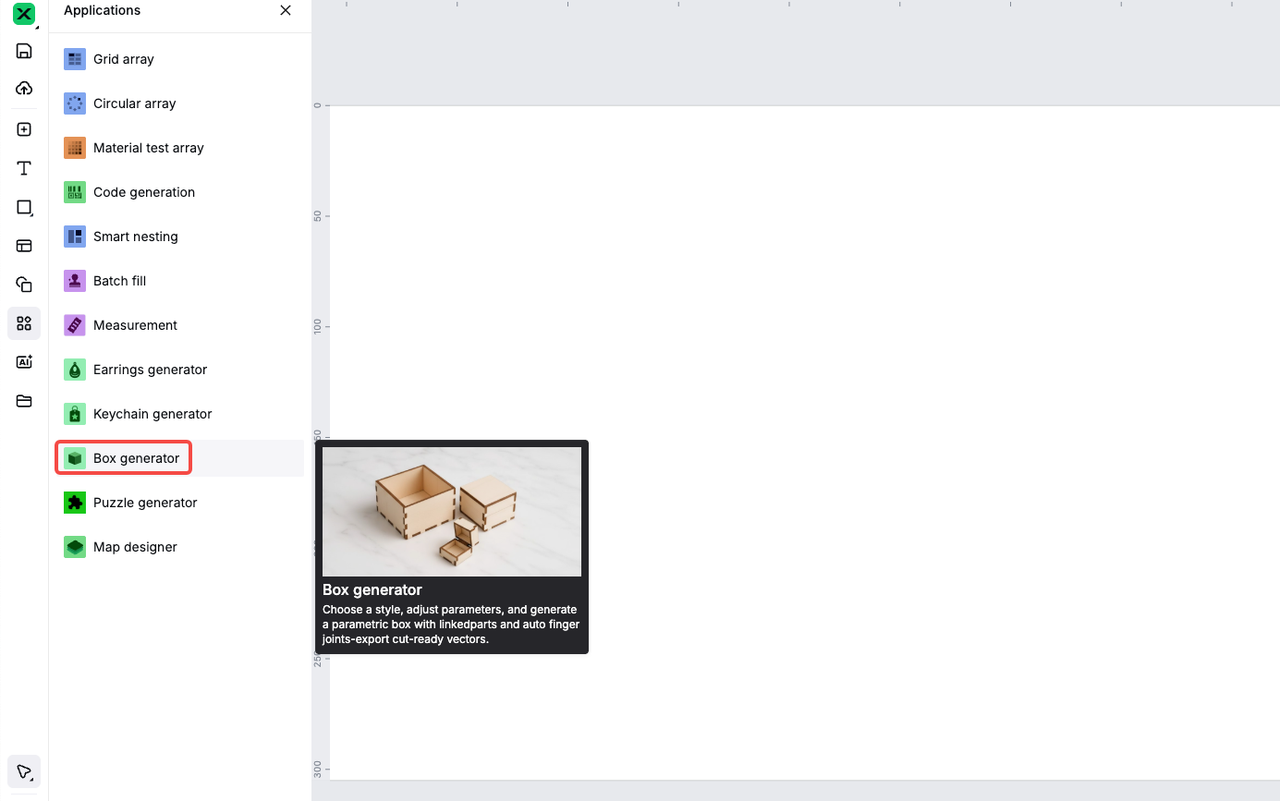

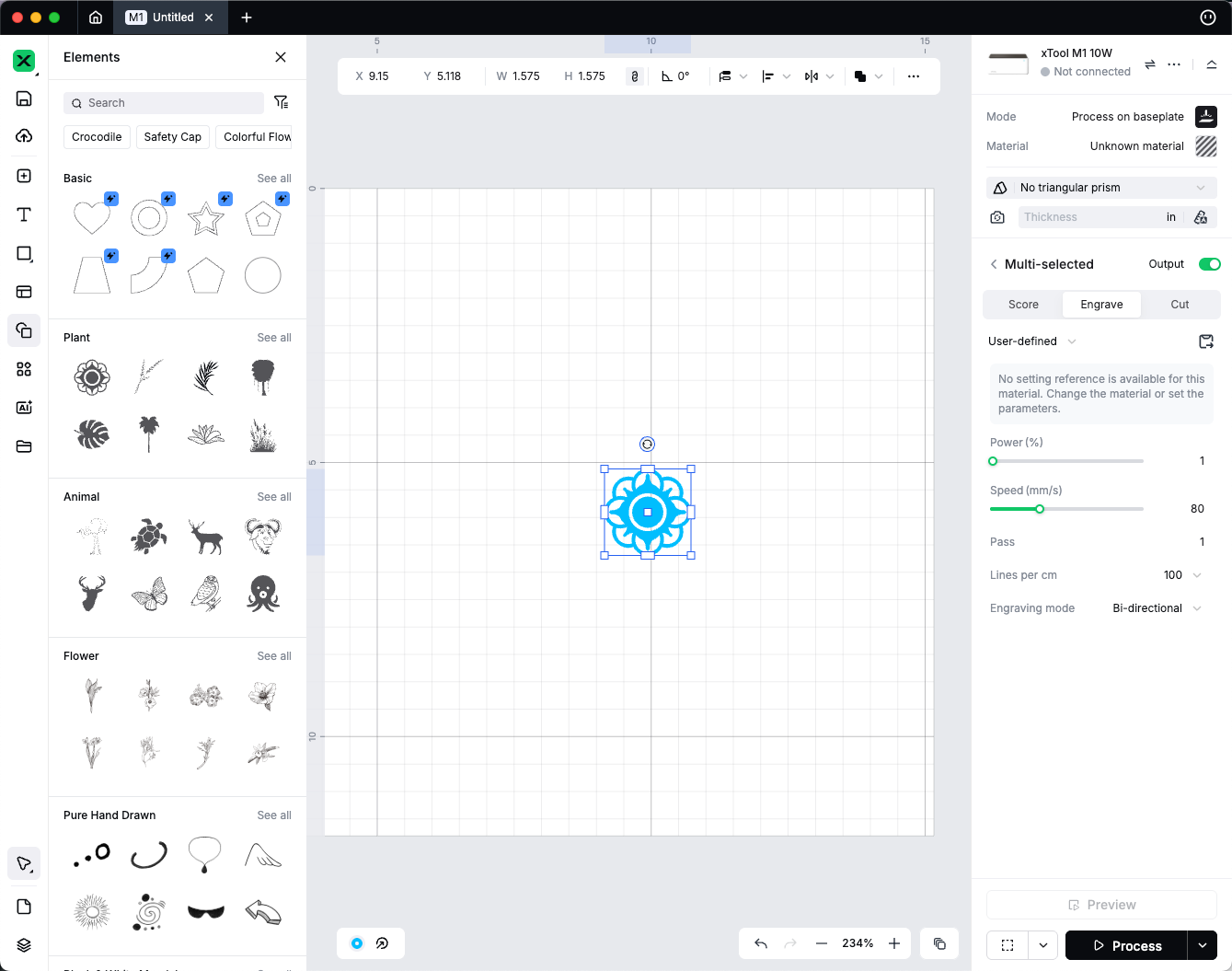

1. Editor - Applications:

- Enhanced UI: Now categorized into "Productivity Tools" and "Generators" to help you find what you need at a glance.

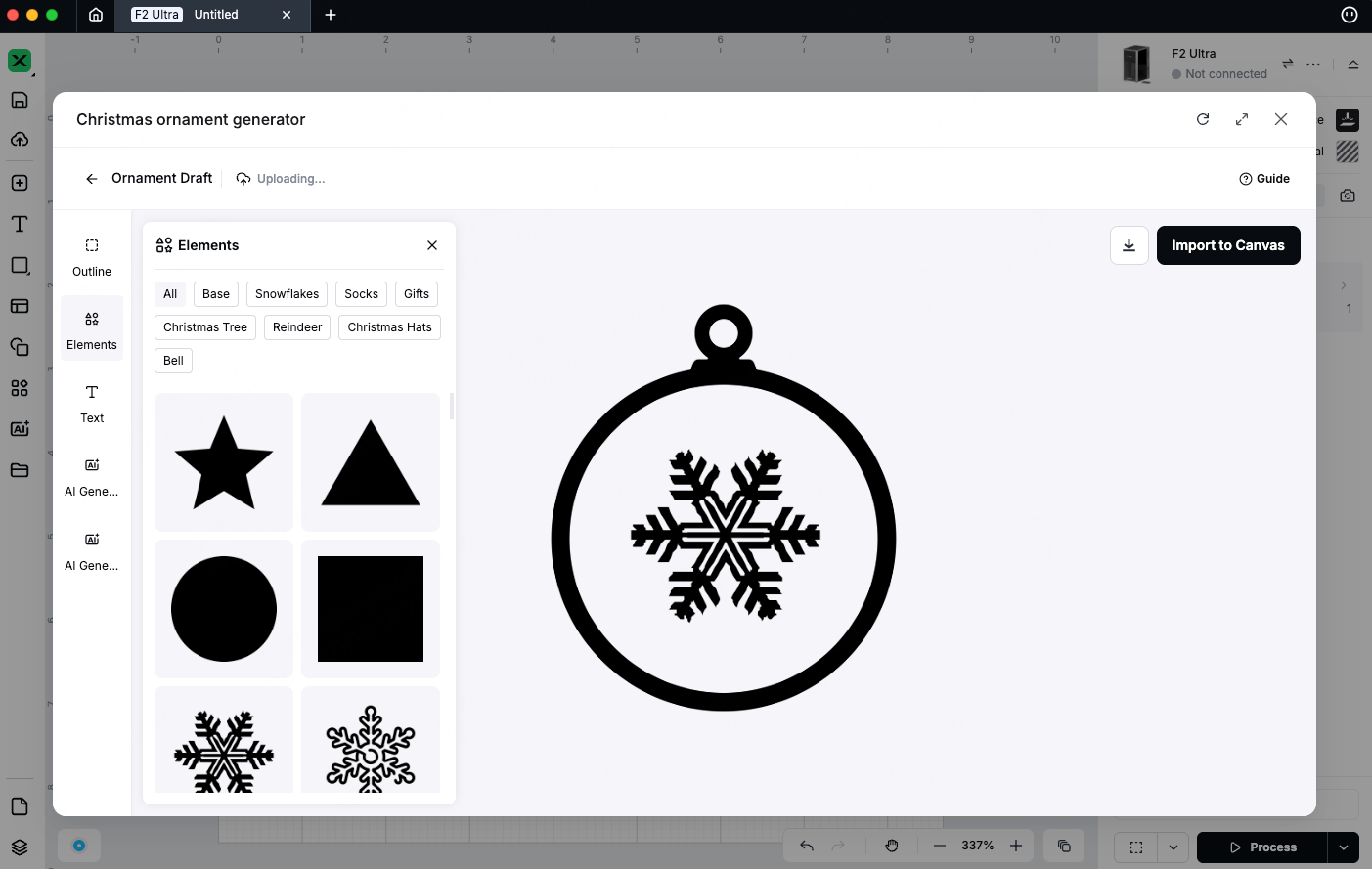

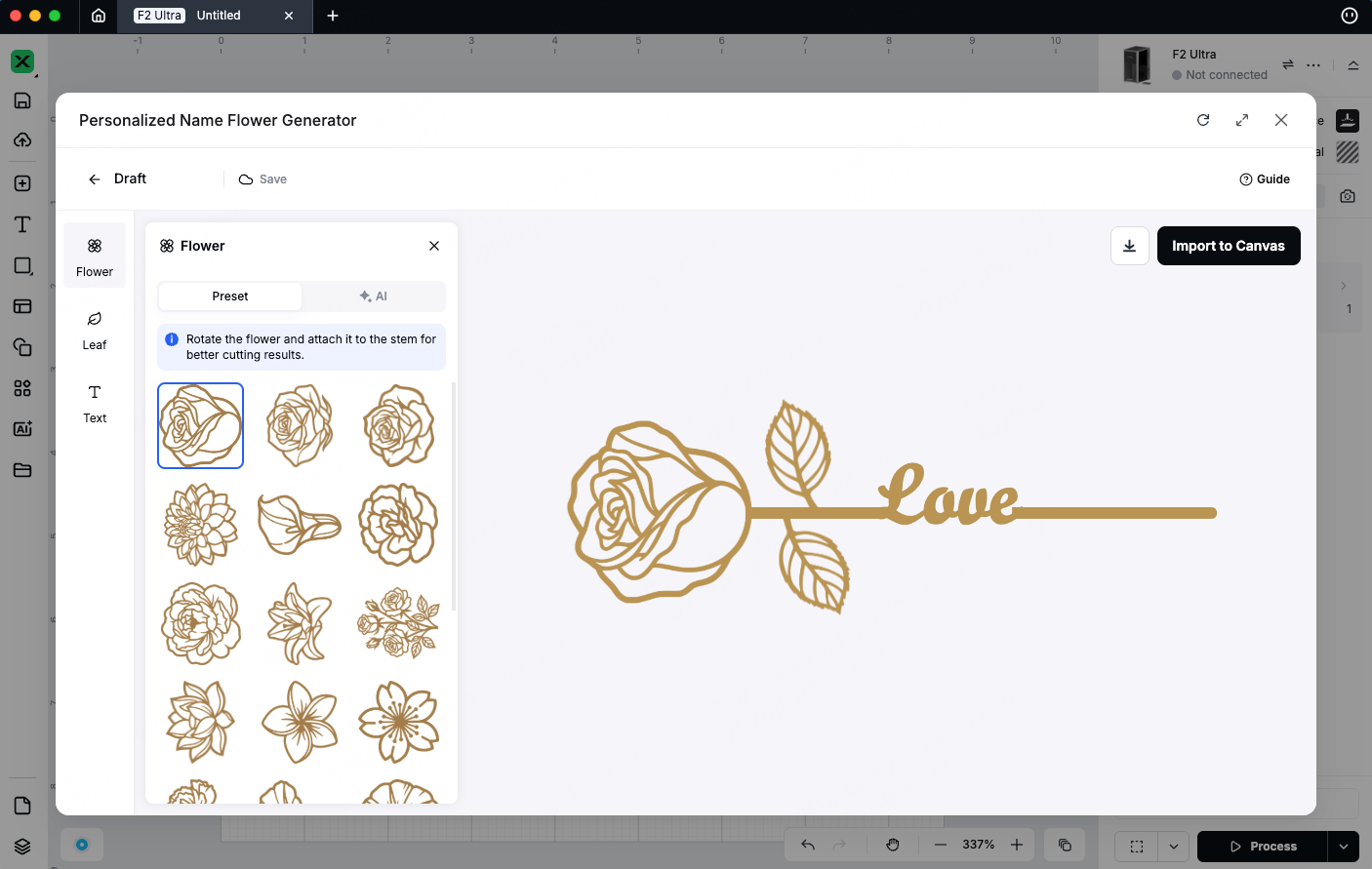

- More Creative Tools: Explore our new Flower Generator and Christmas Ornament Generator—perfect for crafting Valentine’s gifts and personalized ornaments with ease.

2. Object Rotation Optimization:

- Hold Ctrl/Command while rotating to disable 45° auto-snapping for interference-free rotation.

- Hold Shift for stepping rotation in 15° increments.

3. Improved alignment rules for better usability:

- Click-select: Aligns to the last selected object.

- Frame-select: Aligns to the bottom-most object.

4. Smarter Initial Connection: Faster auto-recognition on the first USB plugin. (Official USB cable recommended for optimal results.)

Bug Fixed:

- Fixed auto-masking bug when switching to Eraser on zoomed images.

- Fixed input limit: Text line and letter spacing now support negative values.

- Fixed issue where deleting decimals in spacing inputs would also remove the decimal point.

- Fixed inaccurate time estimation for F-series low-density scanning.

- Fixed intermittent auto-switching from Pointer to Hand tool when using a tablet on the canvas.

- Fixed an issue where parameter settings would incorrectly reset from "Custom Settings" to "Recommended Settings" when reopening a saved project.

- General bug fixes and stability improvements.

xTool Studio Desktop V1.3.6 Release Notes

Version: Desktop V1.3.6

Date: December 28th, 2025

Download link:

Windows Version macOS-Intel Version macOS-M Version

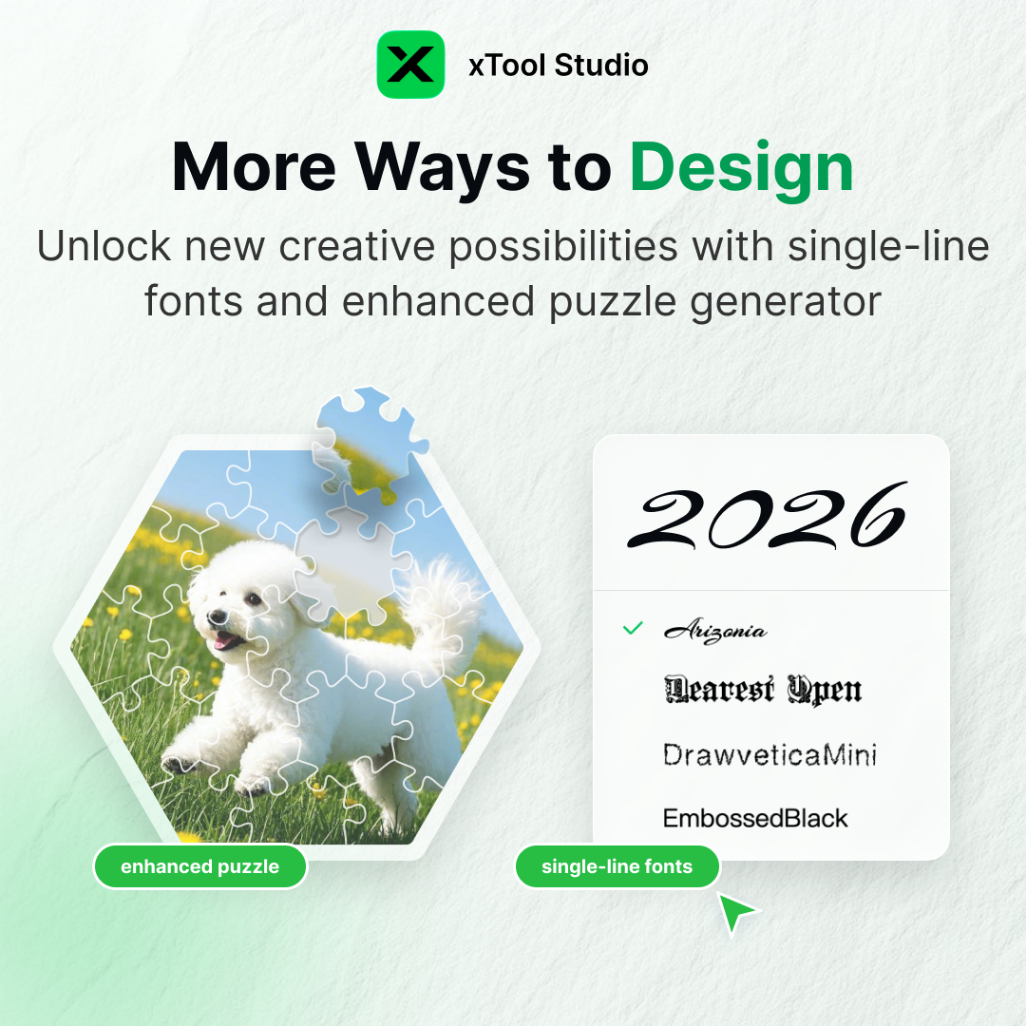

Key Features at a Glance

- xTool Academy: The new "xTool Academy" allows quick access to design and processing knowledge directly within Studio, helping users improve their workflow.

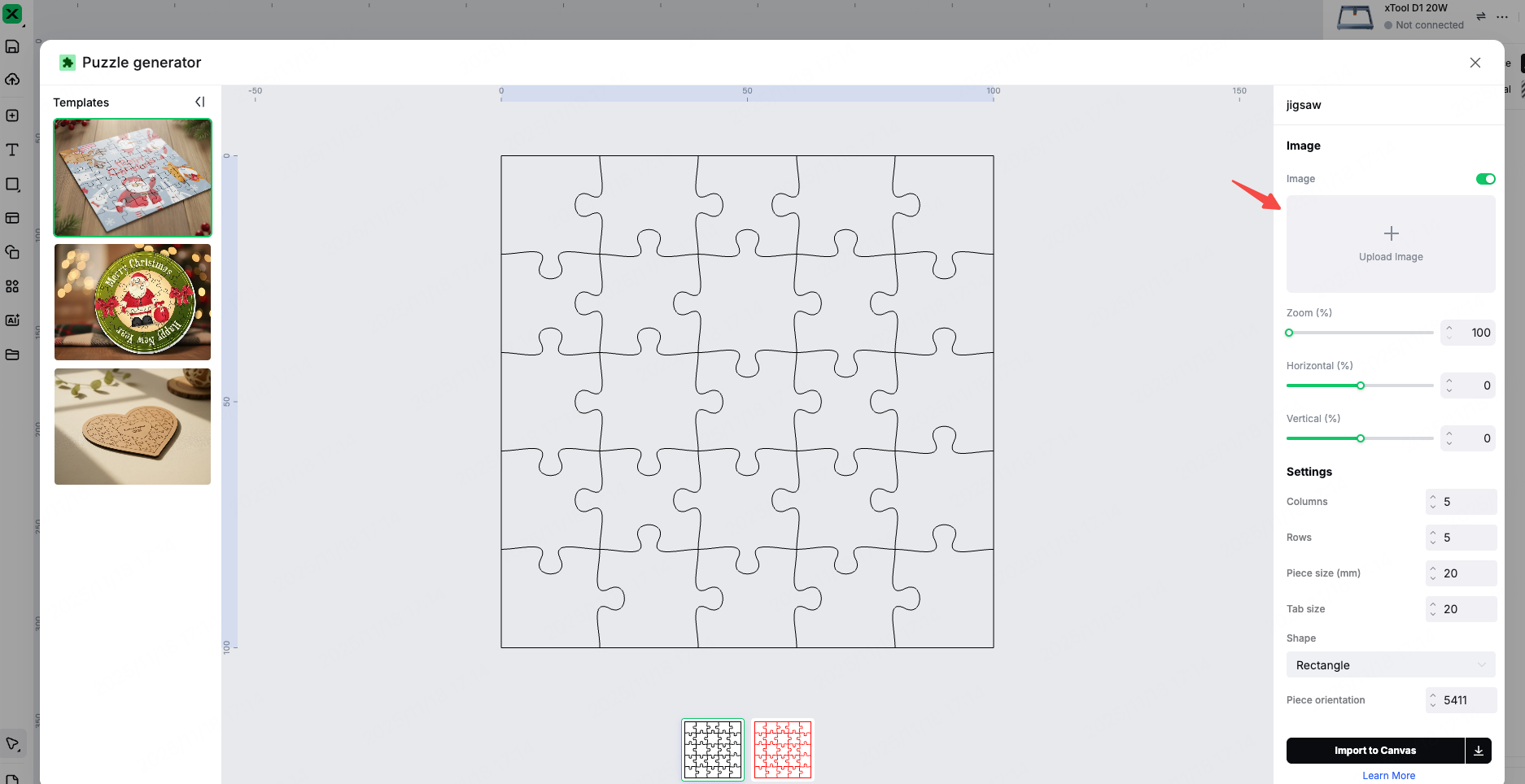

- New Hexagonal Puzzle: Added a regular hexagon puzzle. Supports image upload and puzzle size adjustment.

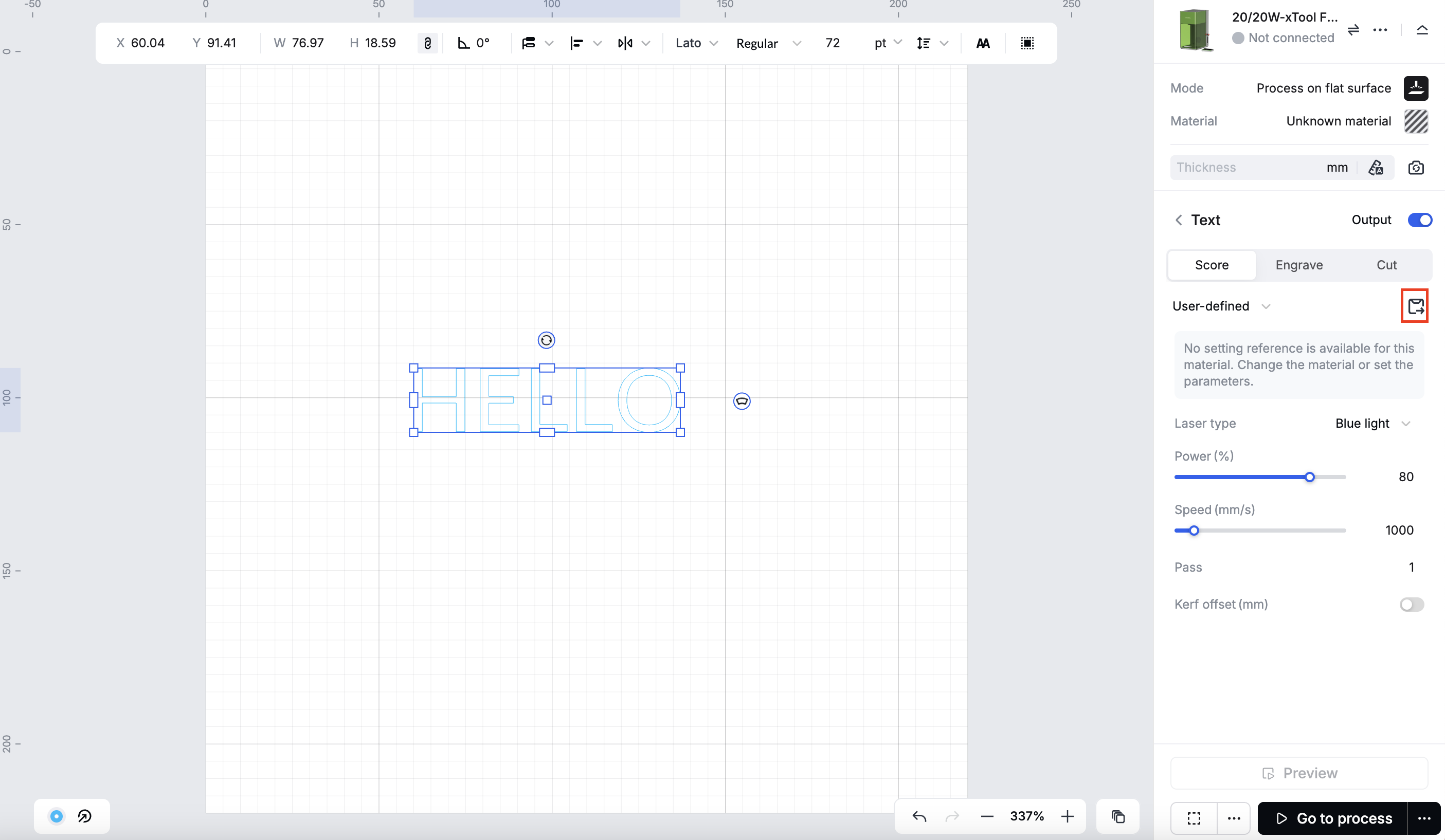

- Parameter Panel Optimization: Added a new "Import Parameter Settings" shortcut for easier parameter scheme import.

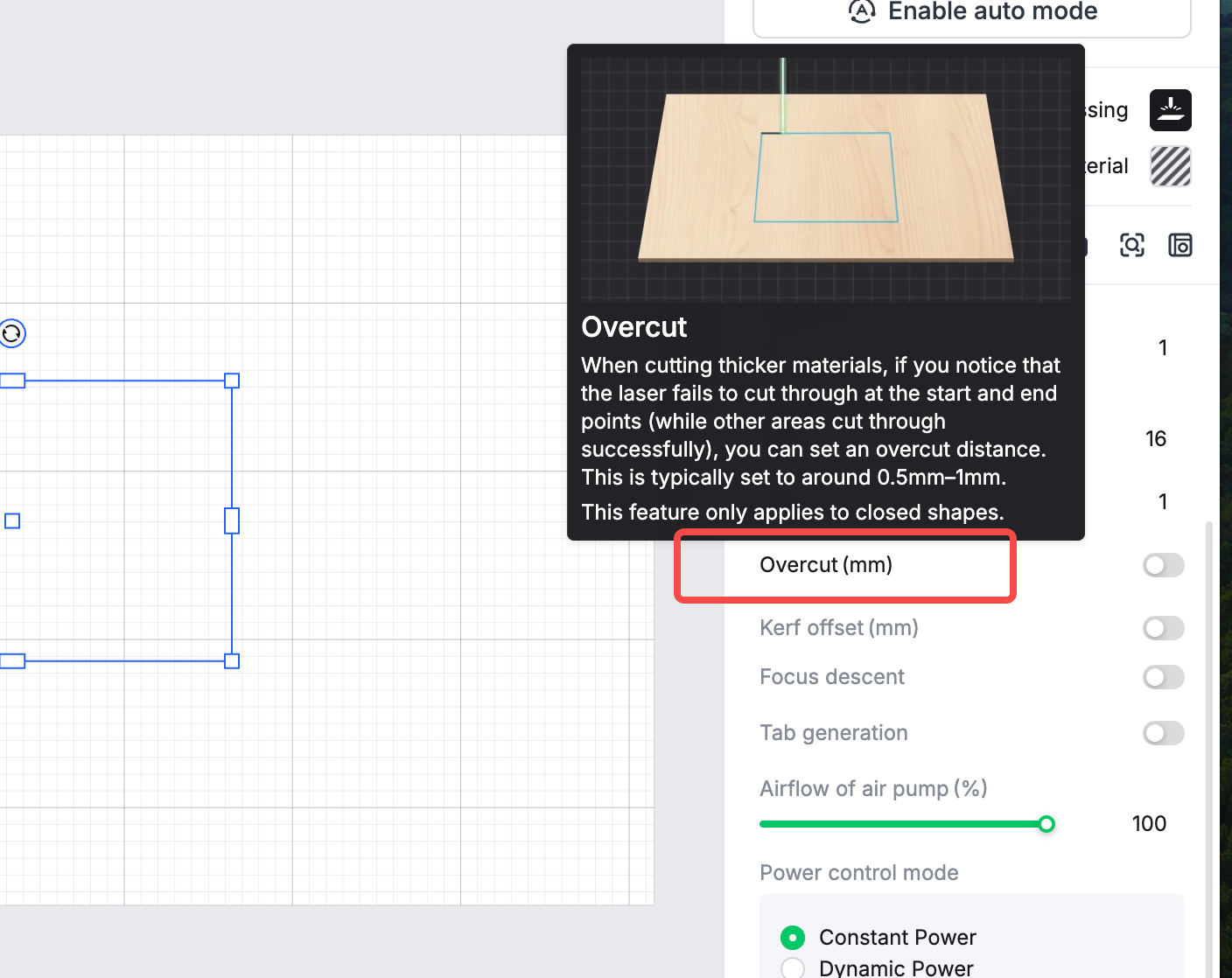

- Overcut: Added an overcut feature in the processing stage to ensure that the start/end connection points are fully cut through, ensuring more complete results. (Only non-F series devices are supported.)

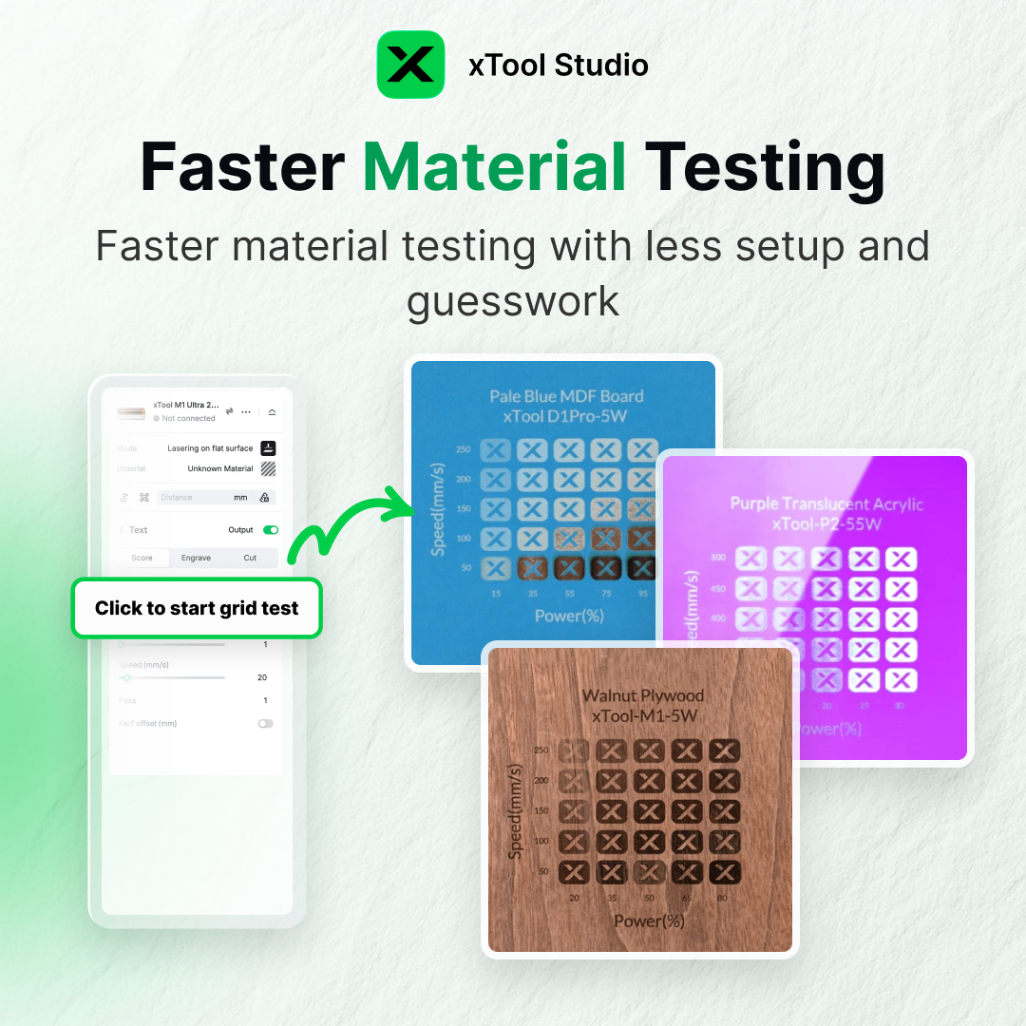

- Material Grid Feature: Supports automatic array generation and a new shortcut entry, simplifying the operation flow and enhancing the user experience.

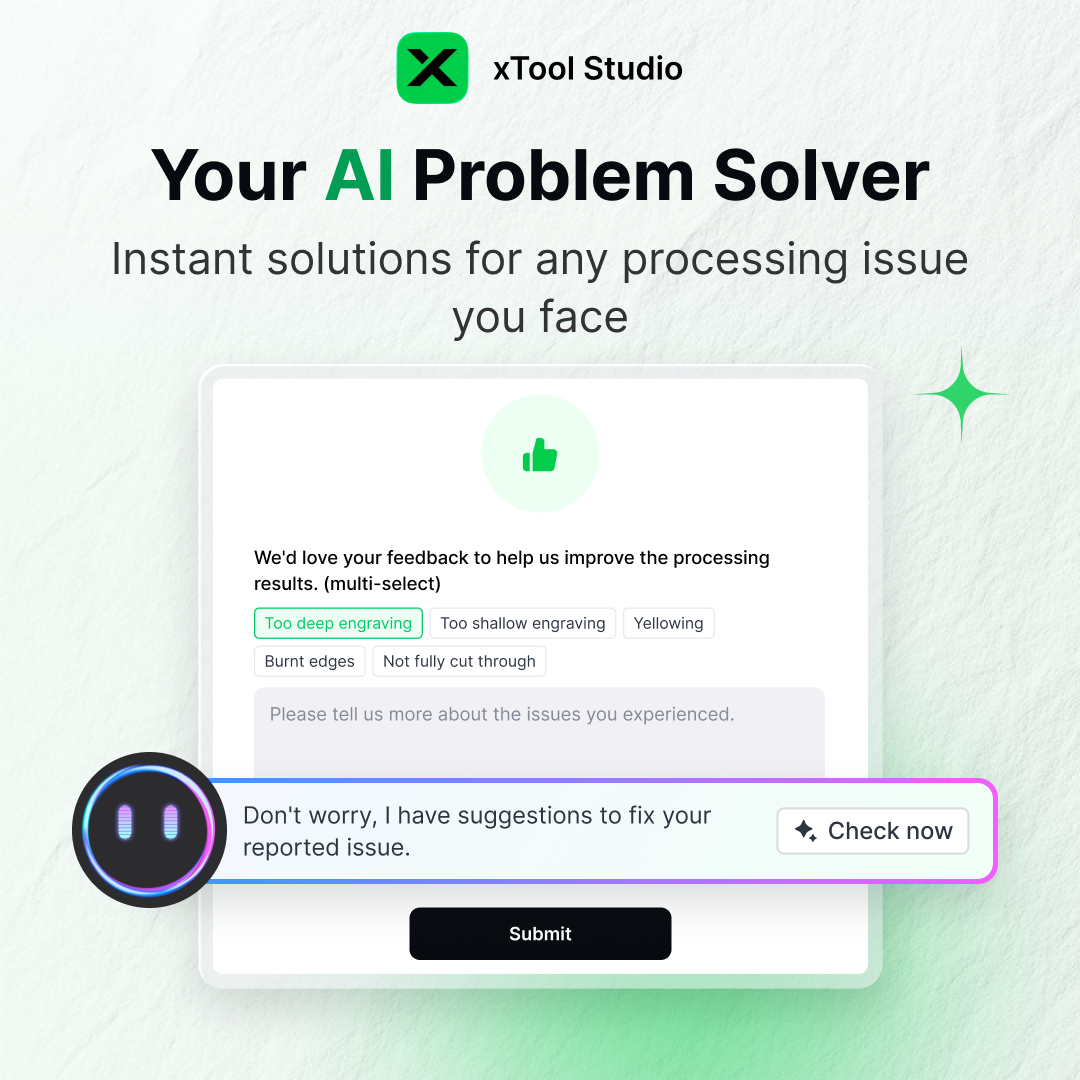

- AI Assistant: Simply select or describe the defects you encountered in your feedback, such as 'engraving too shallow' or 'not cutting through.' The AI will automatically analyze the cause and generate specific parameter adjustment suggestions to help you succeed in your next attempt.

Detailed Updates & Improvements

- Easily access and open a file: Drag and drop a file directly onto the homepage, and it will automatically open on the canvas, ready for editing or further processing. This feature streamlines your workflow by eliminating the need for manual file opening steps.

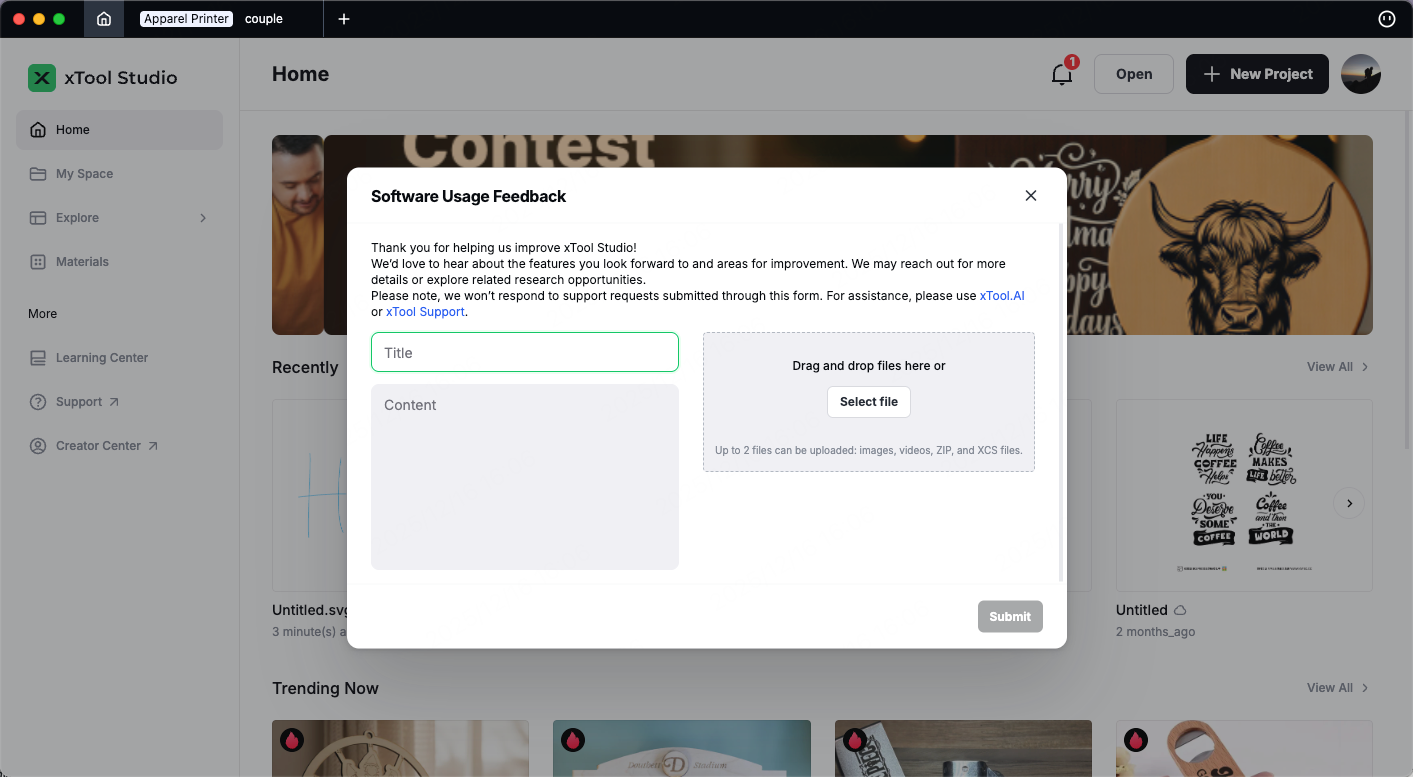

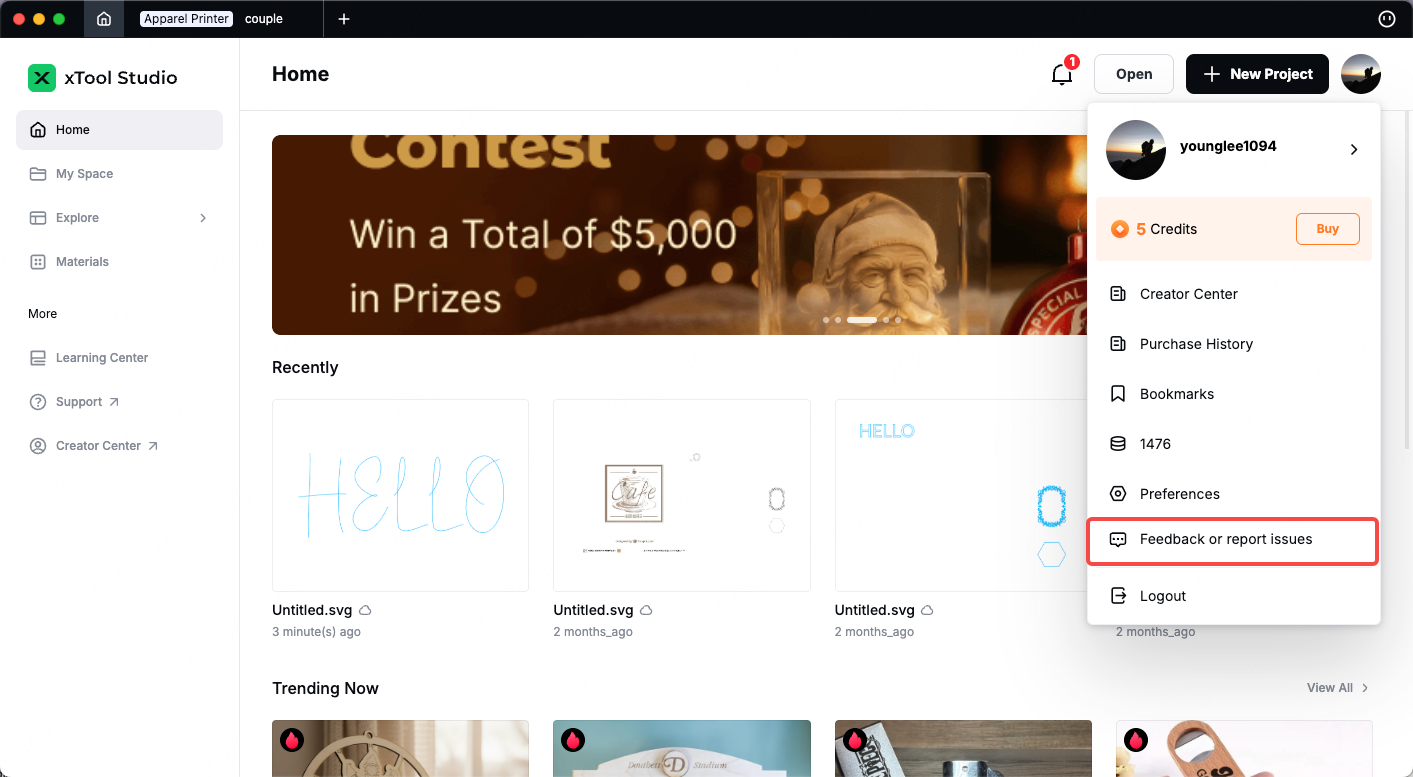

- Feedback or report issues: "Feedback or report issues" feature added to make it easy for users to submit suggestions or report issues, fostering better communication.

- Design bar: The design bar has been optimized with increased height and better information display capacity, providing a more efficient and user-friendly interface for reading and interaction.

- Mouse shortcut actions: You can now press and hold the middle mouse button to drag the canvas, making navigation and editing more intuitive.

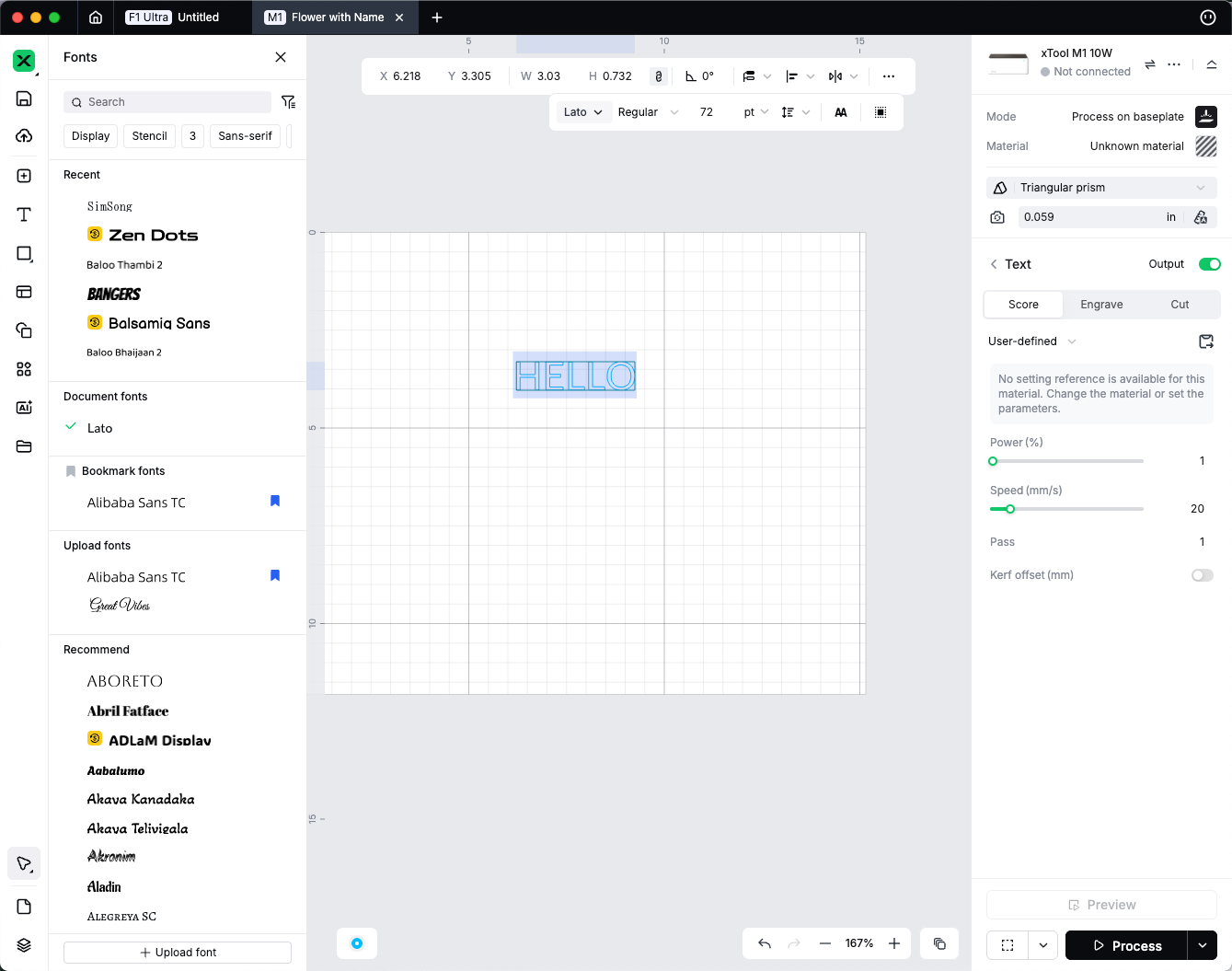

- Text: When adding text, the editor now automatically applies the last used font, weight, and size, reducing repetitive adjustments and saving time.

- Rectangular arrays: The maximum row and column limit for rectangular arrays has been increased, allowing you to create larger, more complex arrays with greater flexibility to suit your design needs.

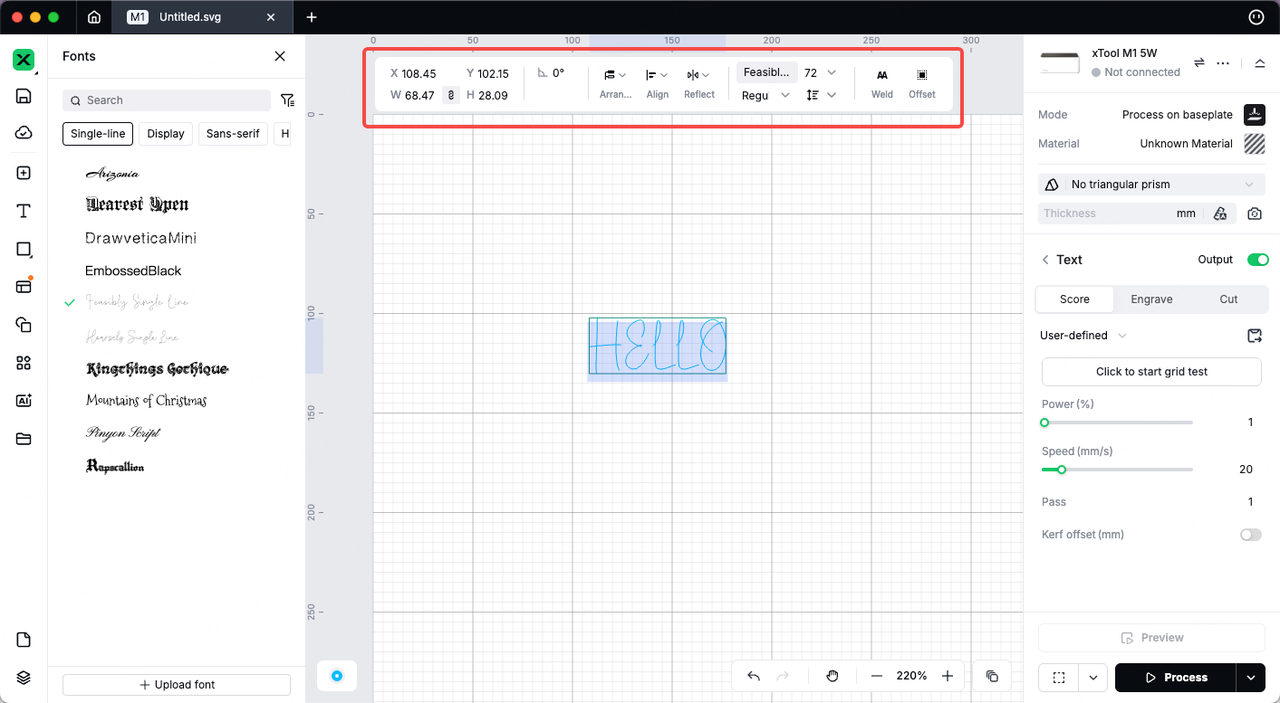

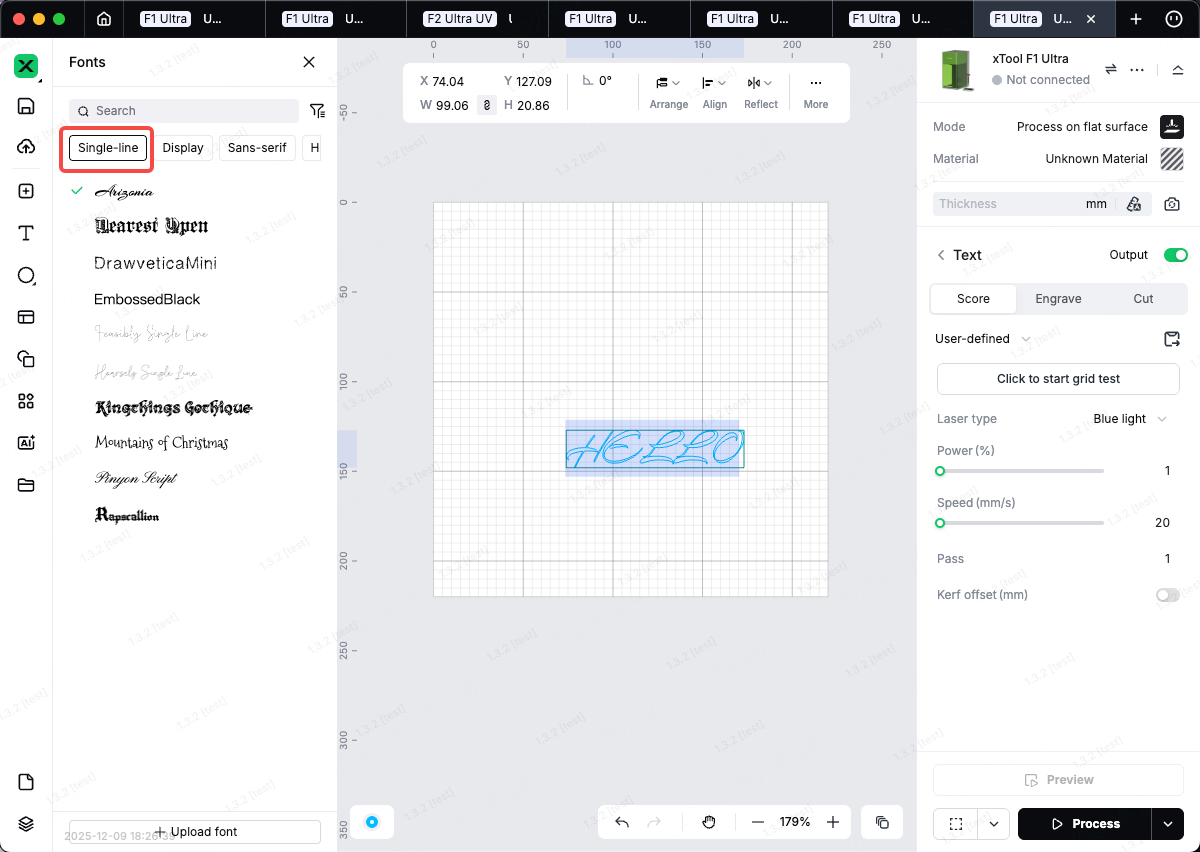

- Single-line font: a new collection of "Single-Line" has been added to the font library, offering more font styles for designers to choose from.

- New Hexagonal Puzzle: Added a regular hexagon puzzle. Supports image upload and puzzle size adjustment.

- Overall Size Indicator: Overall size hint. The canvas ruler shows the total puzzle size.

- Piece Orientation Dropdown: Offer four different puzzle piece orientation combination options.

- Border Feature: Supports generating a puzzle border and backing board, with adjustable border width.

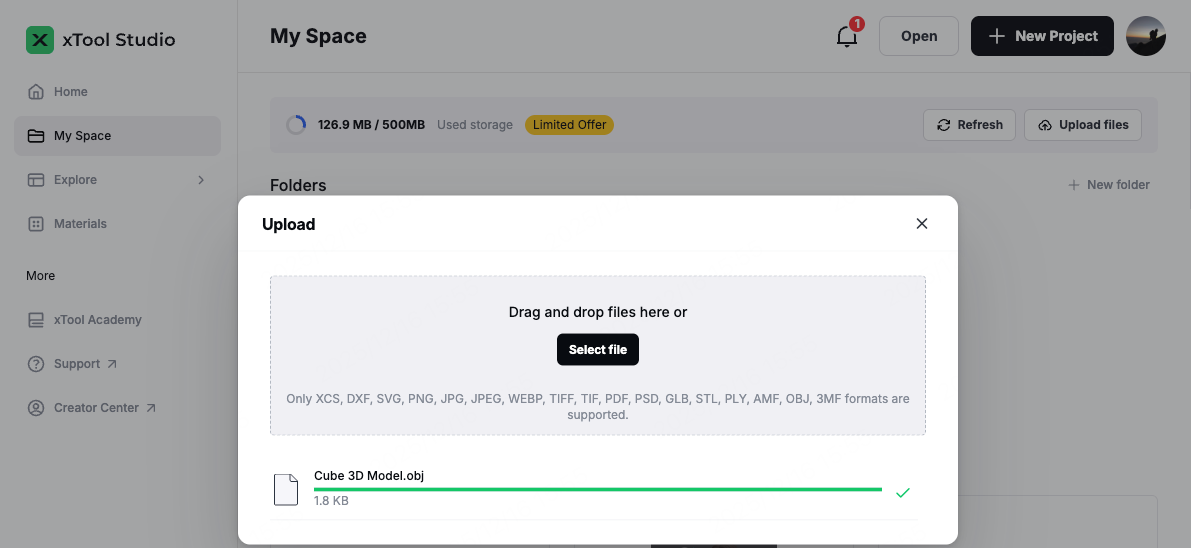

- 3D model: "My Space" and the canvas now support uploading 3D model formats, enabling these models to be used as assets across multiple projects. Supported formats include STL, OBJ, AMF, 3MF, GLB, FBX, and PLY, broadening the options for creative work.

Device-related updates:

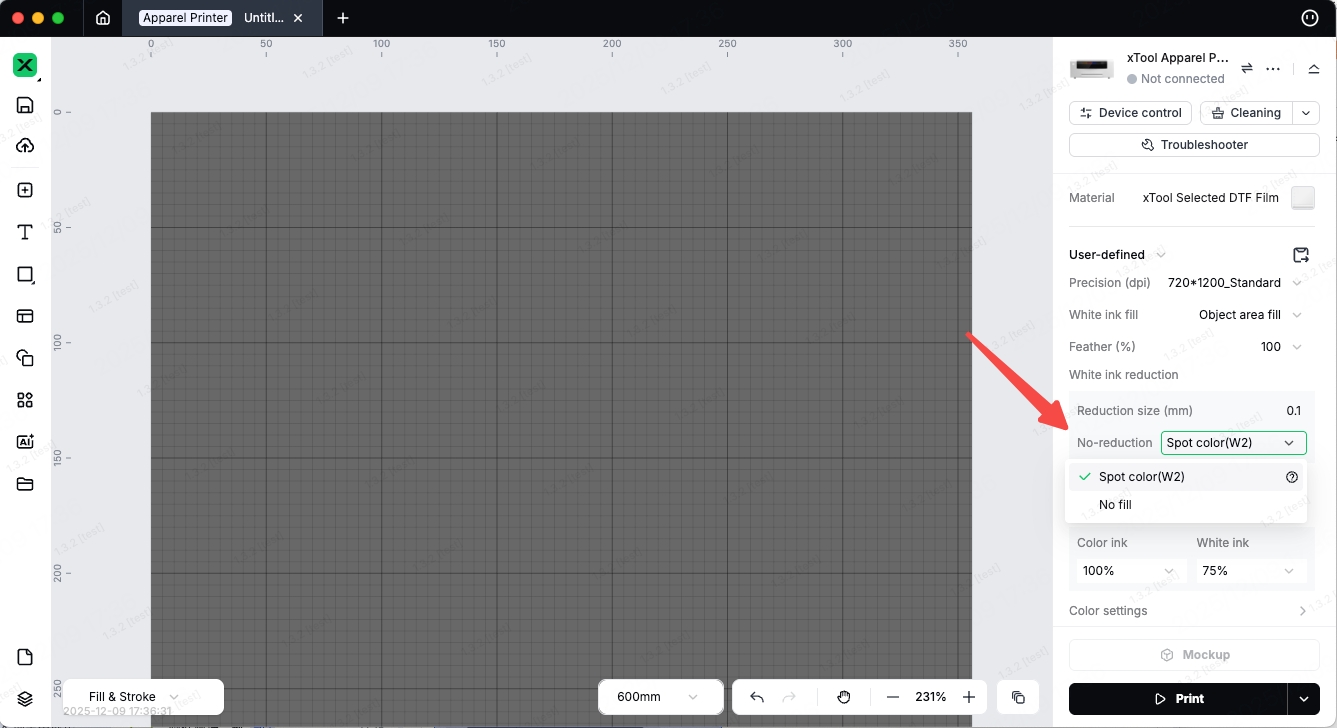

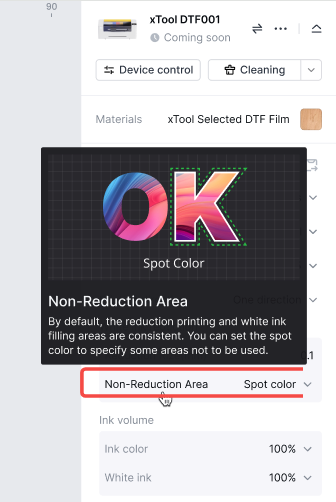

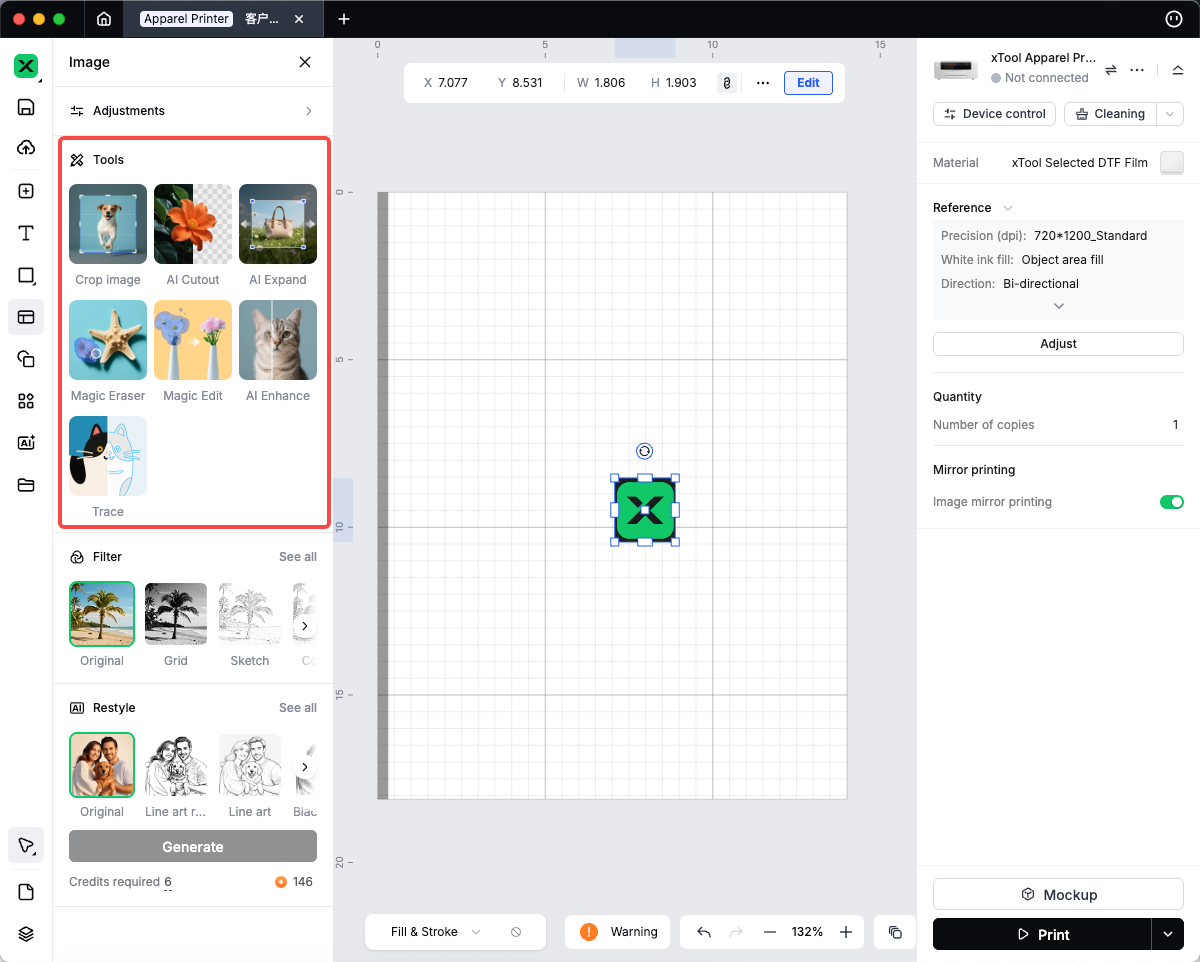

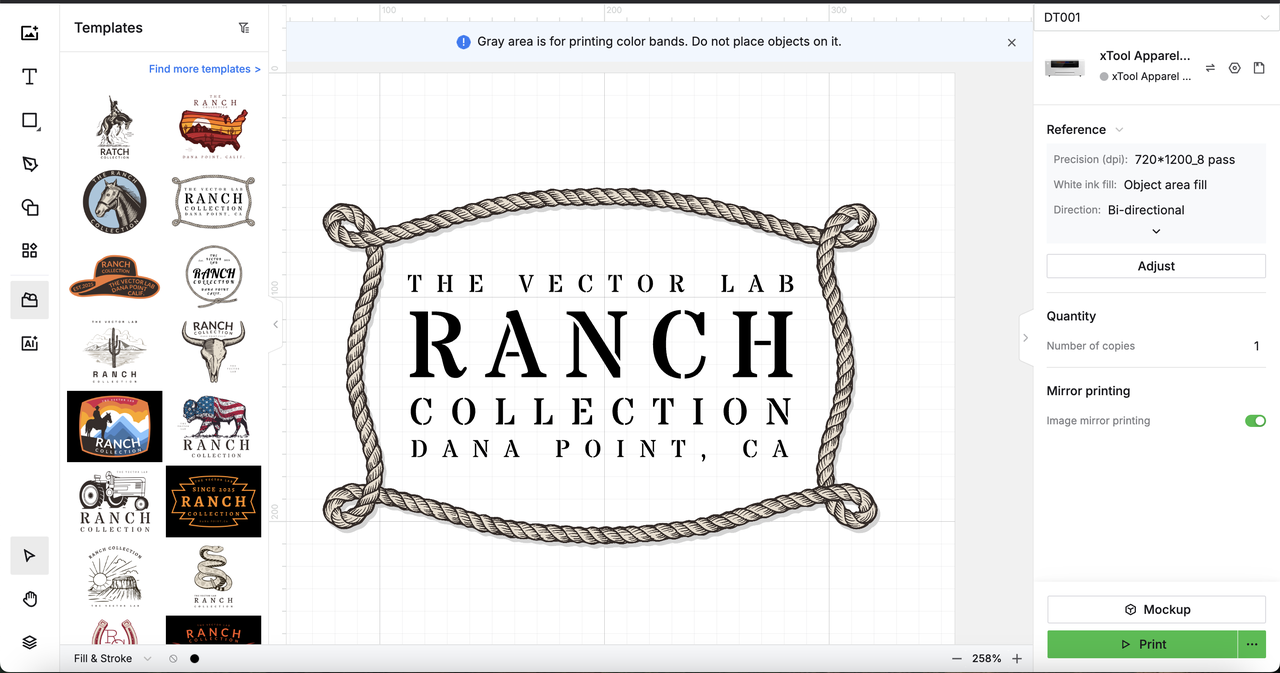

- Apparel Printer Print Function Optimization: Optimized the white ink reduction function, supporting setting non-reduction areas through spot color channels to enhance print diversity.

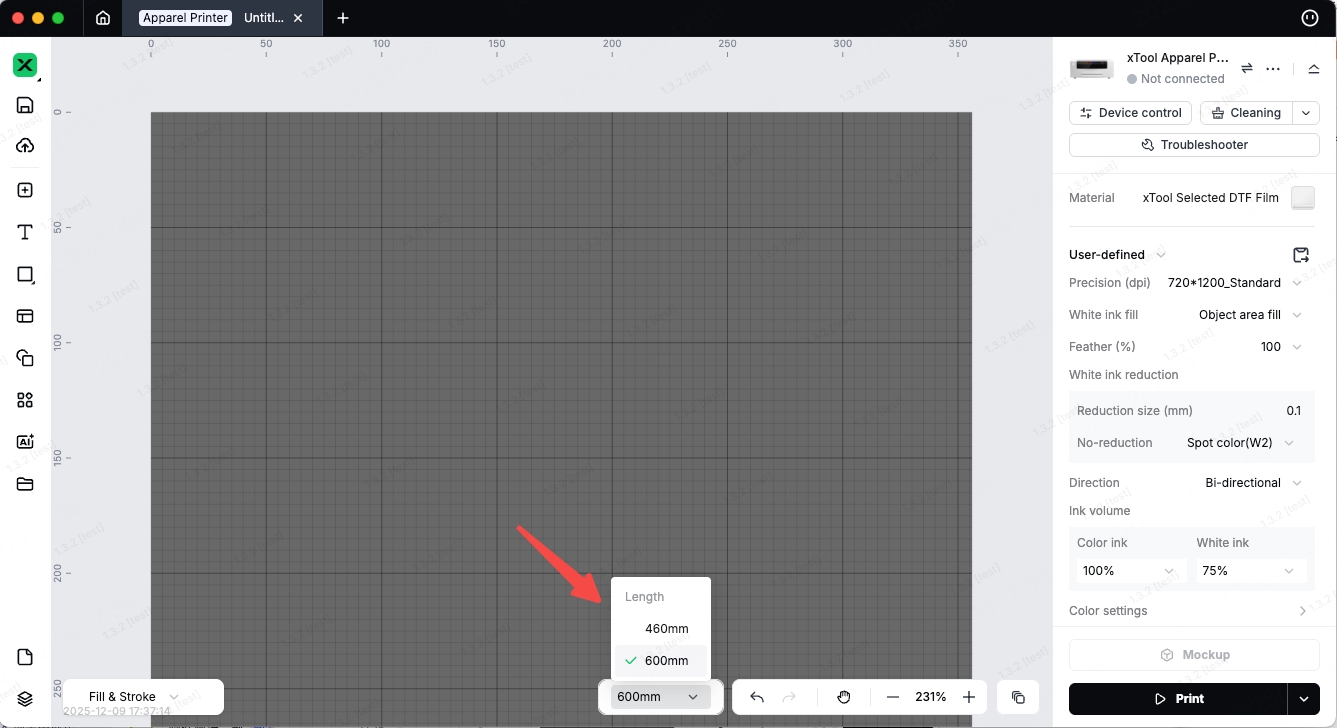

- Apparel Printer Long-Material Printing: Adds support for 600 mm long-material printing, expanding the device’s application scenarios to meet a wider range of production needs.

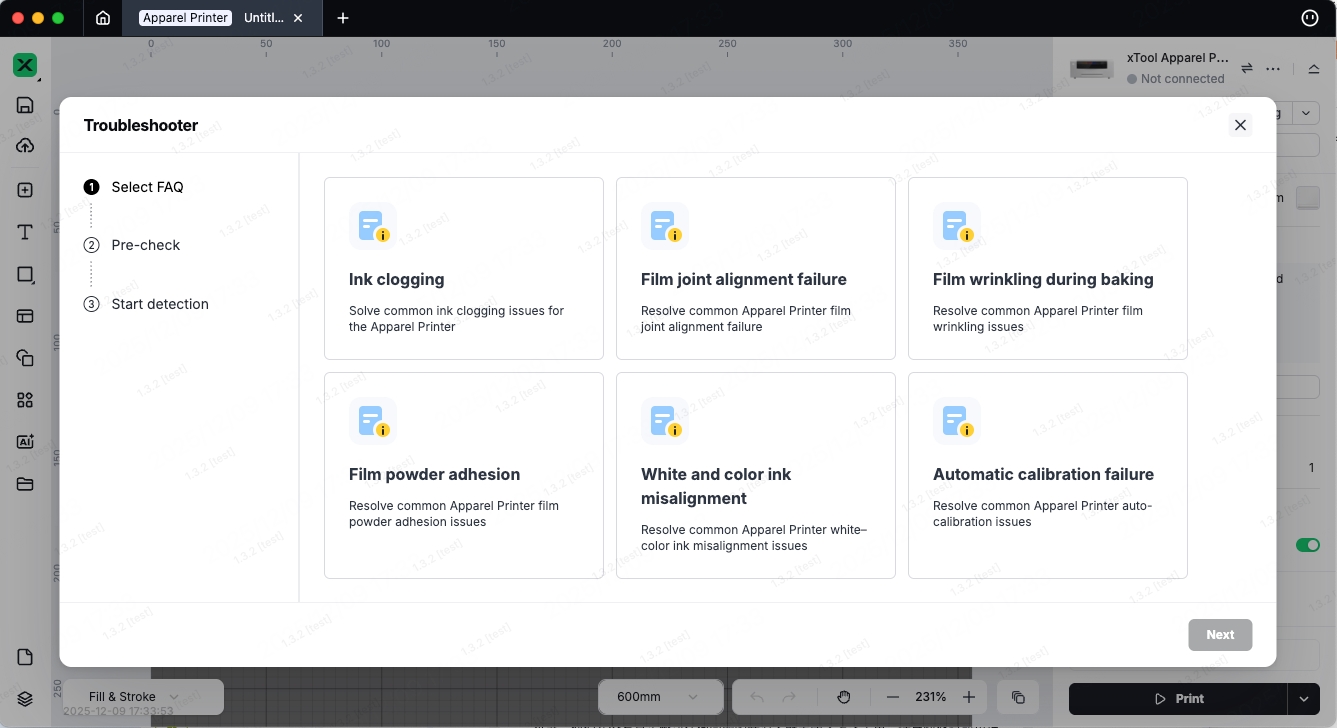

- Apparel Printer Self-Troubleshooting: Added five new self-service troubleshooting features to help users quickly resolve common issues, preventing work interruptions.

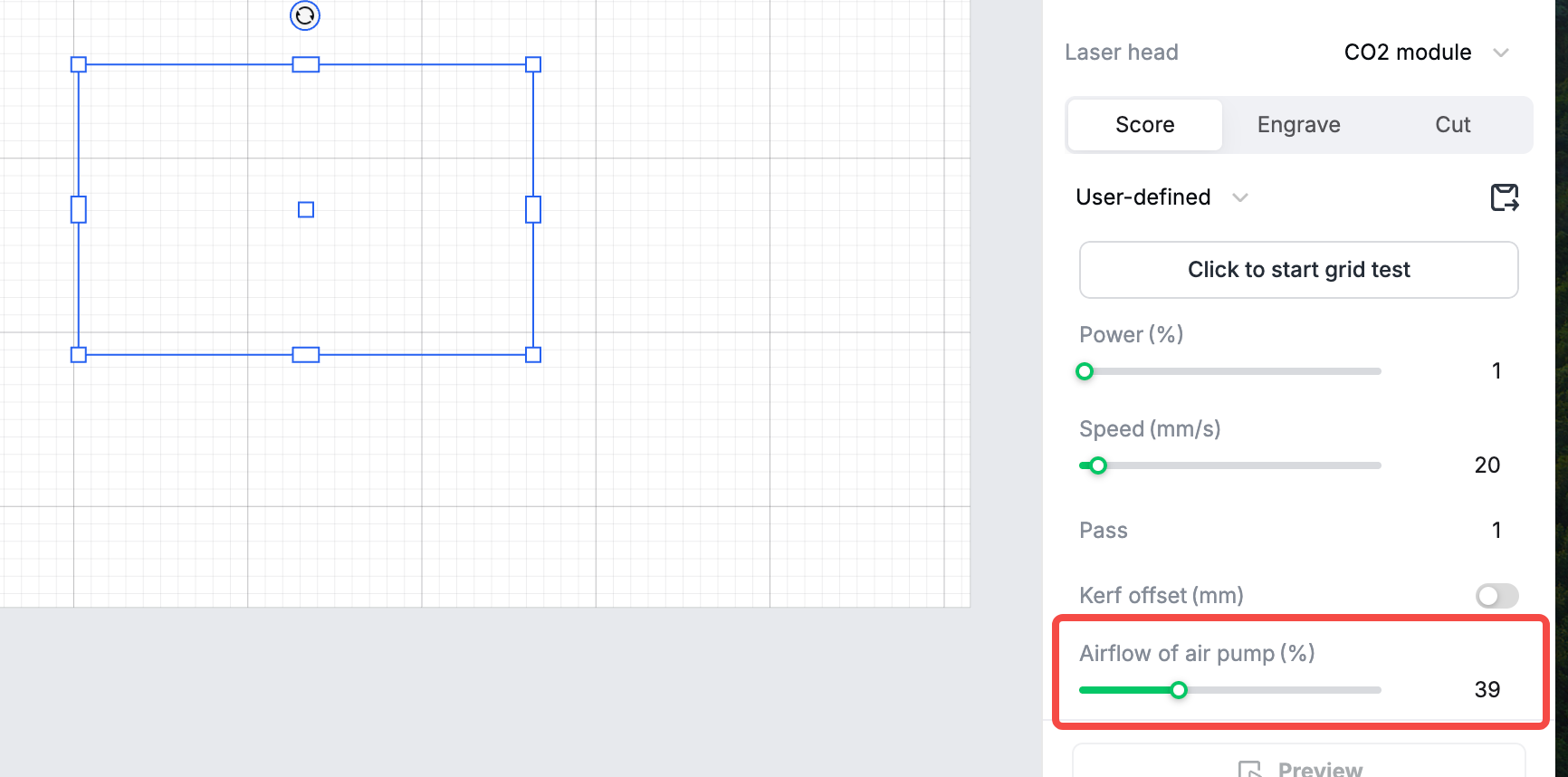

- Supports directly adjusting air pump values in the parameter panel. (Only supported on P2 / P2S / P3.)

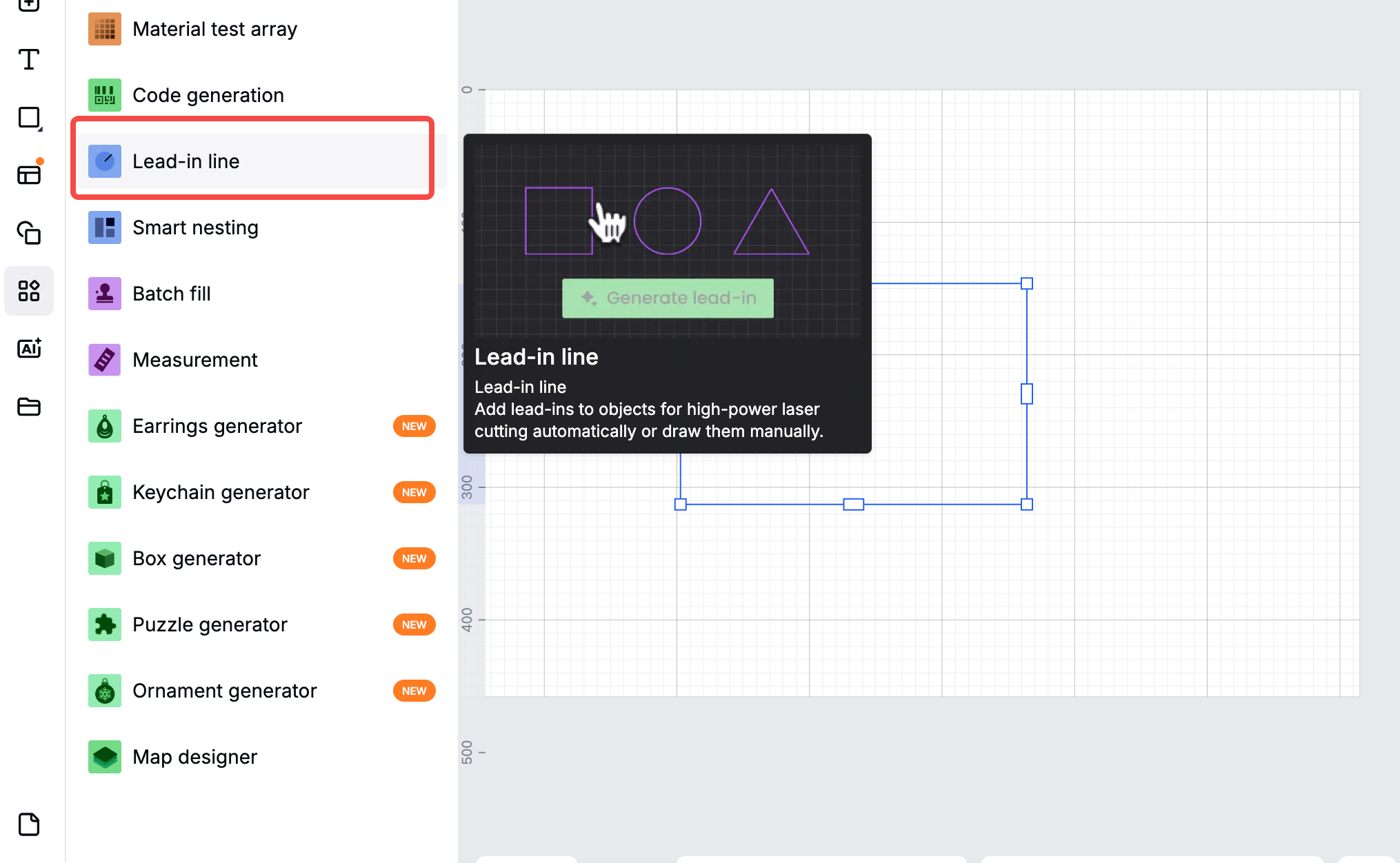

- P3 supports the lead-in line feature, which can resolve the issue of darkening at the starting point.

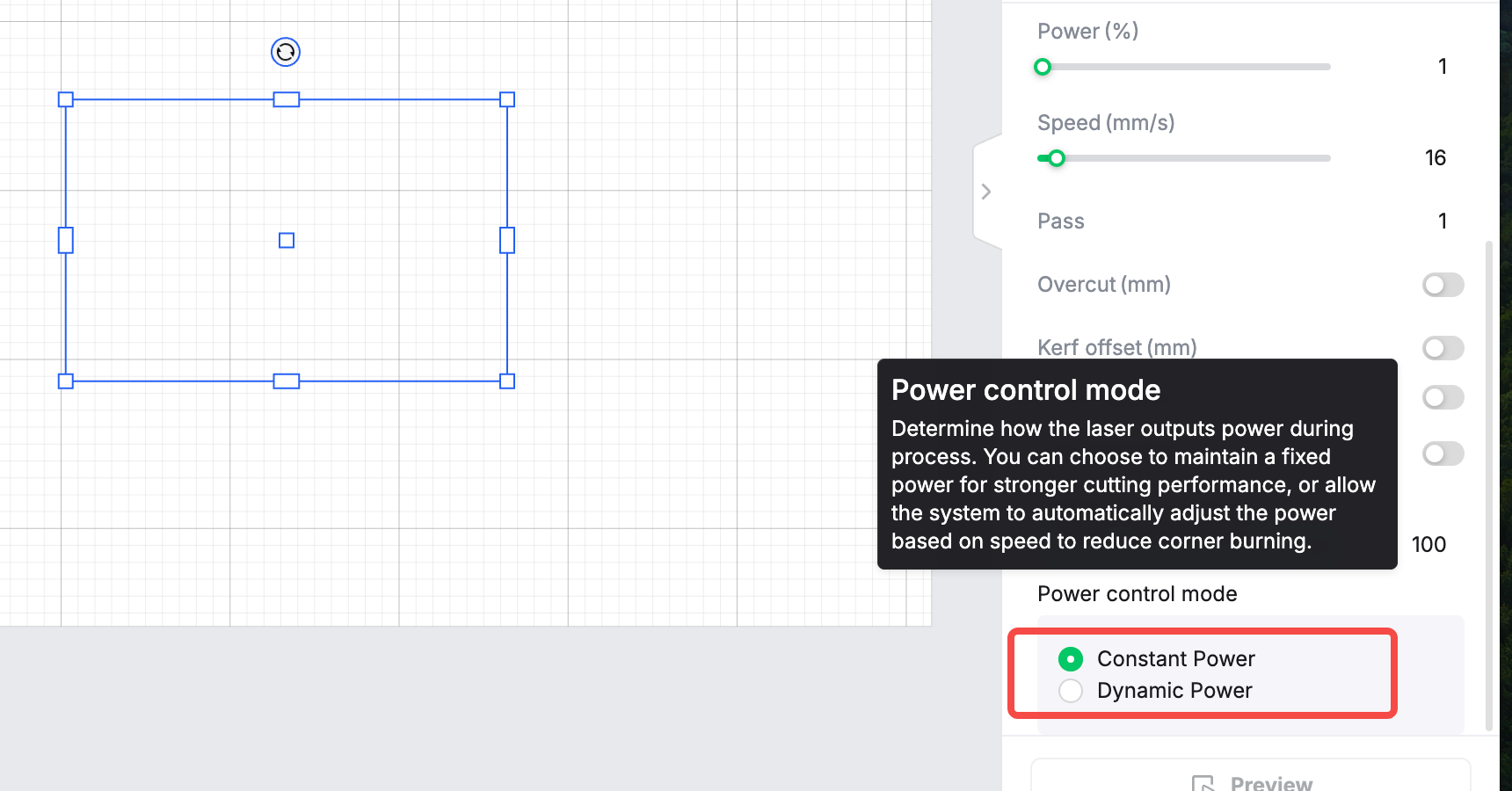

- P3 supports directly modifying the power control mode in the parameter panel.

- Added an overcut feature to resolve the issue where the connection between the start and end points is not fully cut through.

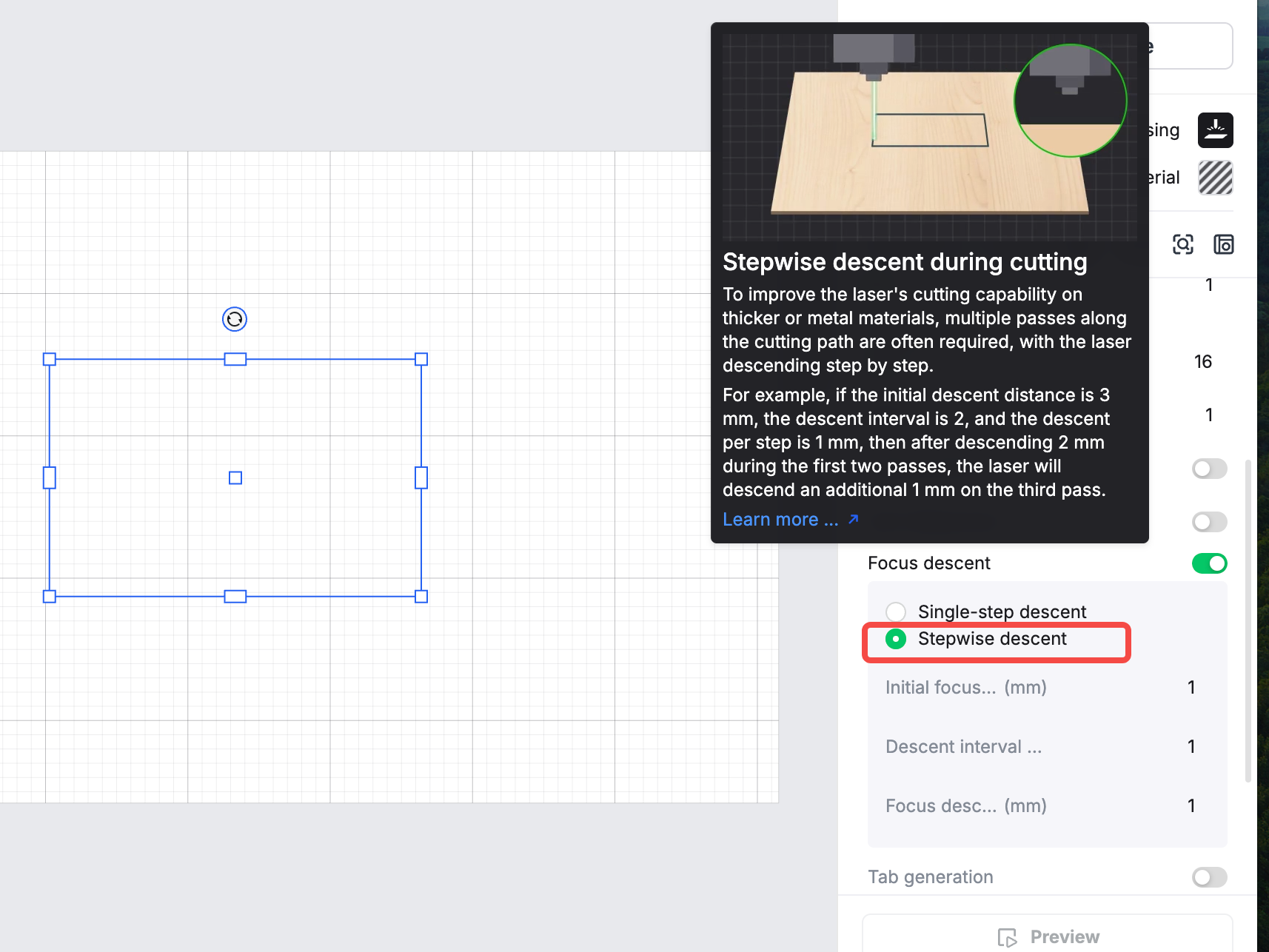

- Focus descent supports stepwise descent, which can significantly enhance cutting capability.

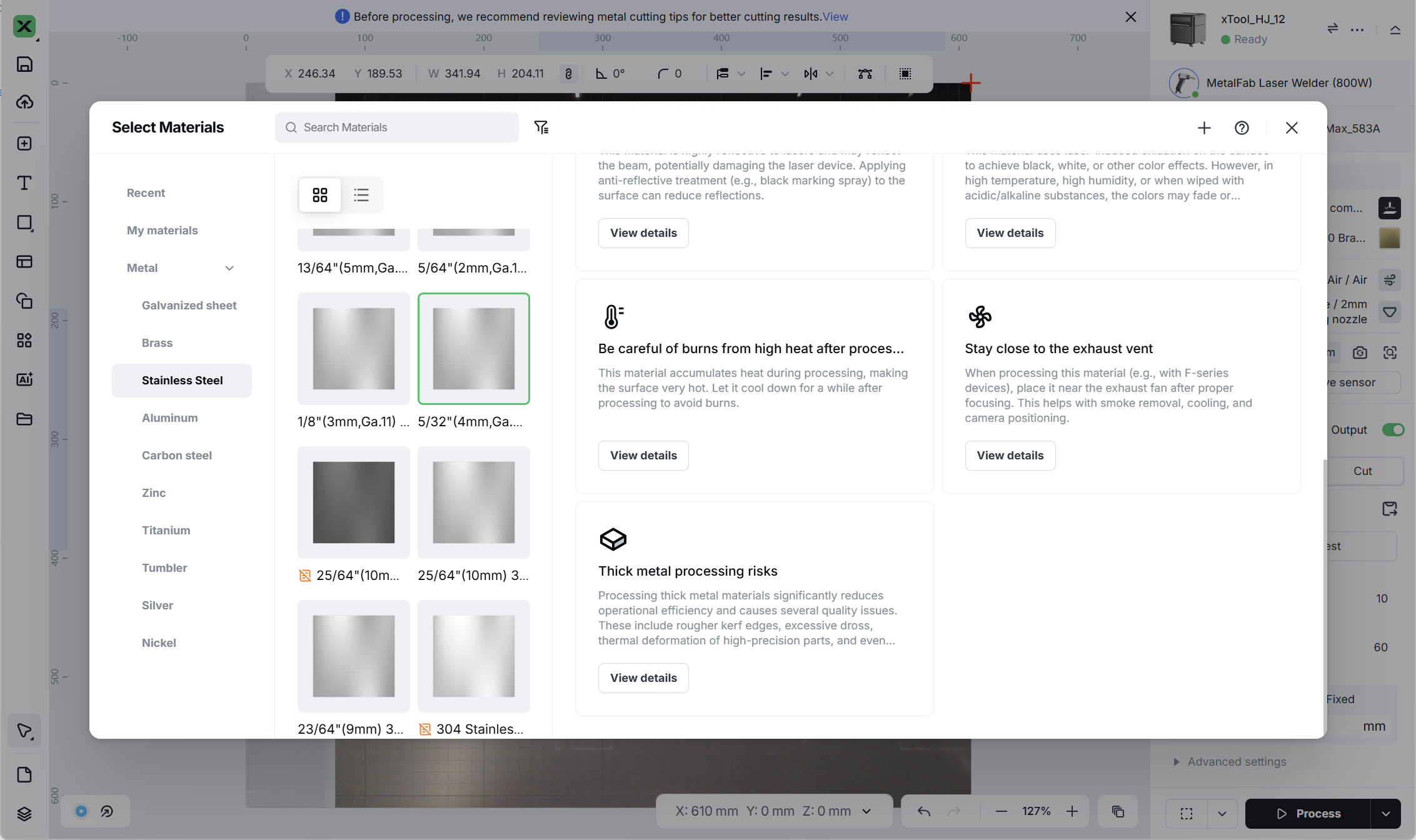

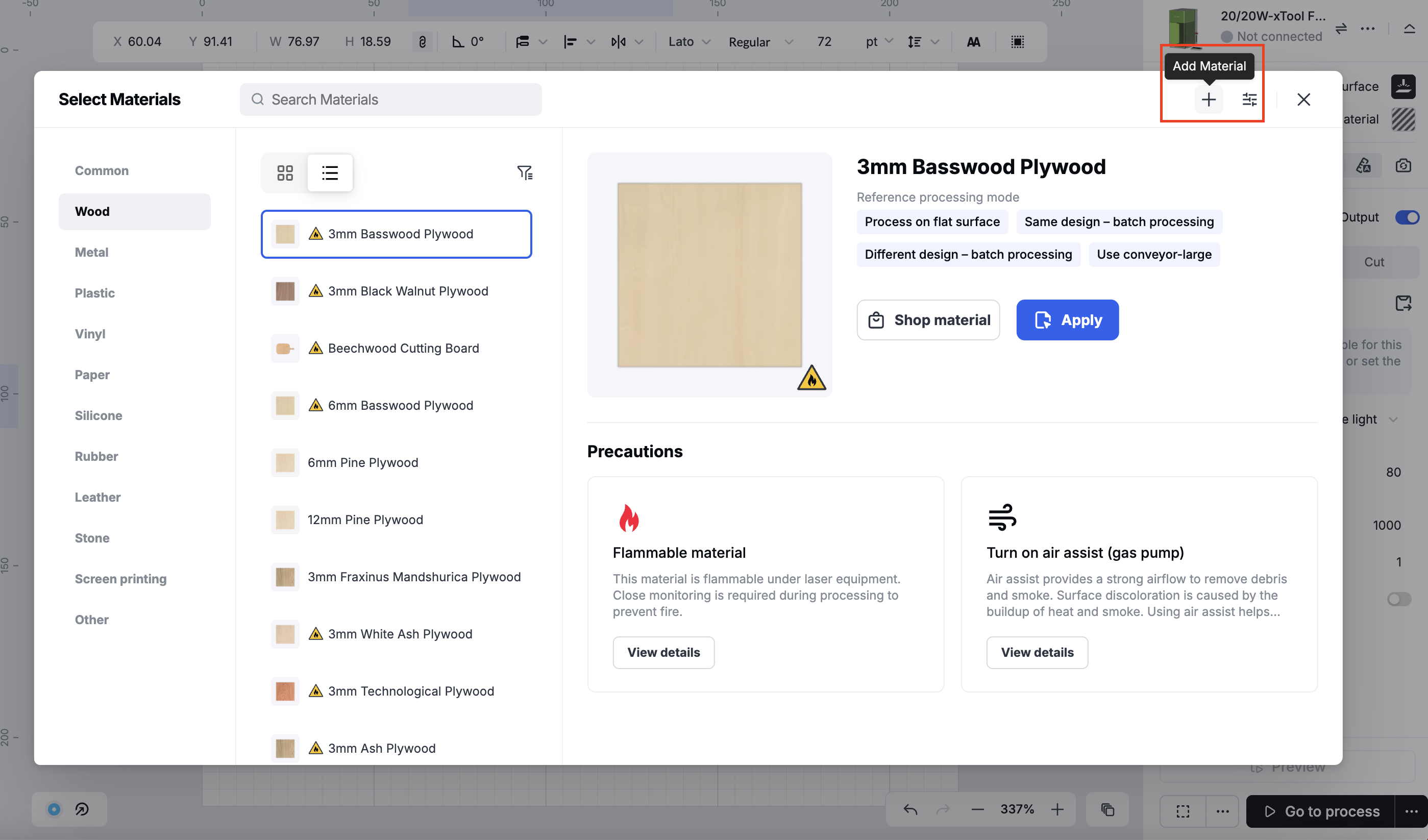

Material-related updates:

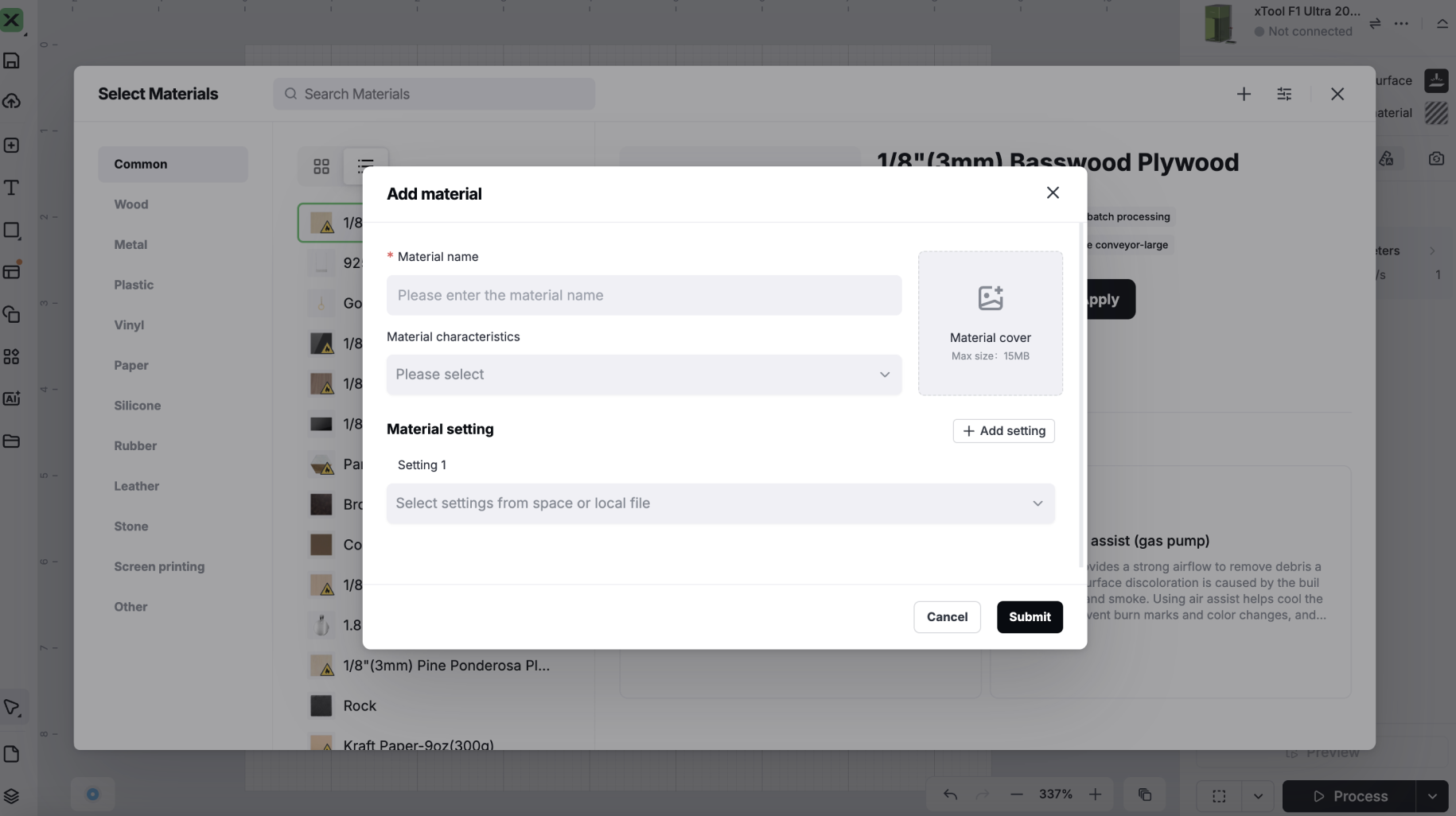

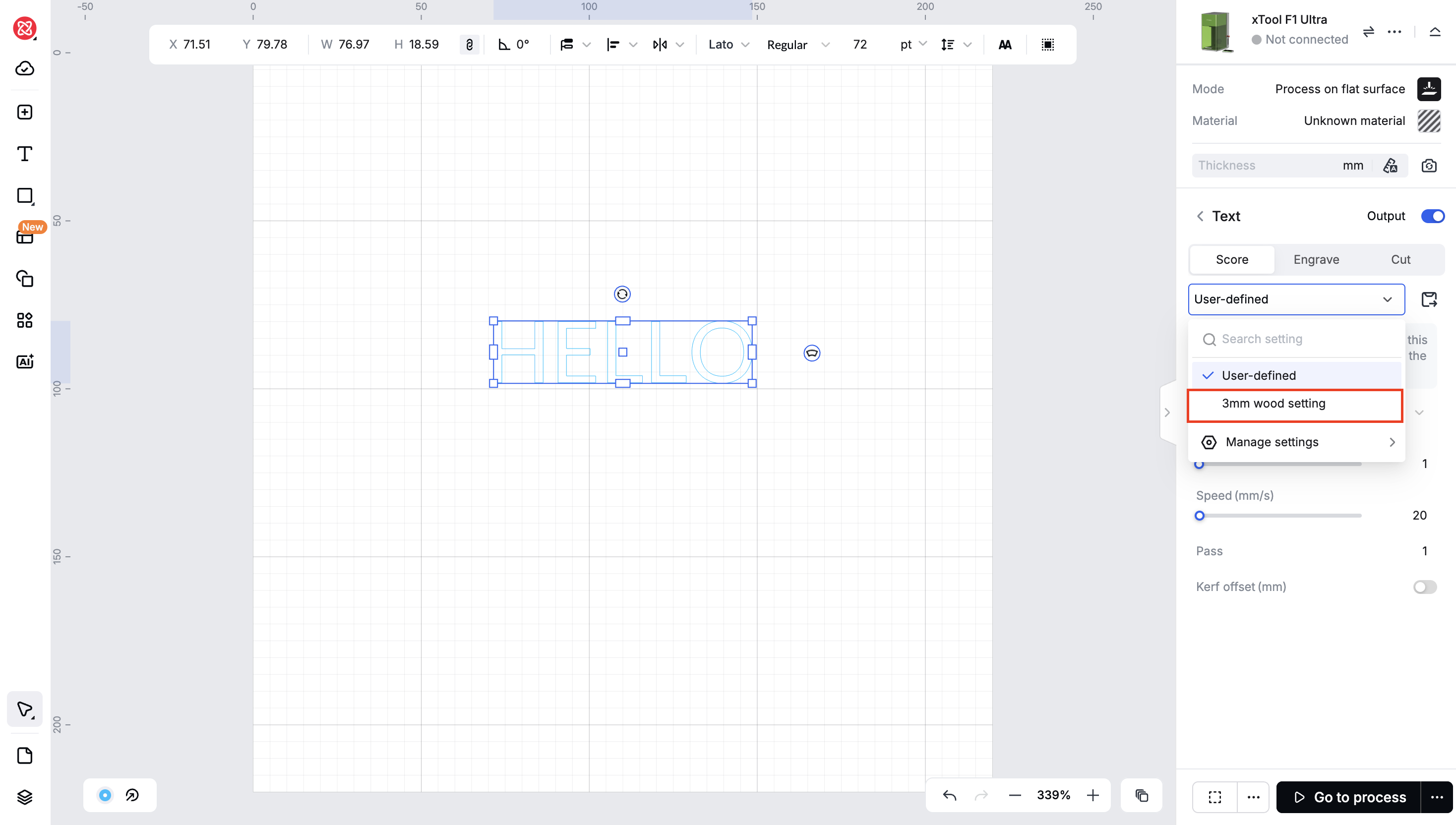

- Parameter Panel Optimization: Added a new "Import Parameter Settings" shortcut for easier parameter scheme import.

- Flammable Material Popup Reminder: After applying a flammable material, the flammable warning prompt will be automatically canceled.

- Material Grid Shortcut: A new shortcut for material grid testing has been added under "Unknown Materials" to enhance operational convenience.

- Material Selection Popup Optimization: Saved materials can now be edited in the "My Materials" and "Recent" tabs.

- Distance Measurement Optimization: When measuring thickness/diameter data, if the applied material lacks relevant information, entered values will not be cleared, preventing unnecessary data loss.

Bug fix:

- Resolved an issue causing origin coordinates to shift after rotating objects and incorrect dimension display.

- Resolved the issue of coordinate origin change and abnormal dimension display after object rotation.

xTool Studio Desktop V1.2.11 Release Notes

Version: Desktop V1.2.11

Date: November 26th, 2025

Download link:

Windows Version macOS-Intel Version macOS-M Version

Key Features at a Glance

Detailed Updates & Improvements

- File compatibility enhancement: Added direct import of PDF and PSD files for better integration with your design-to-production workflow.

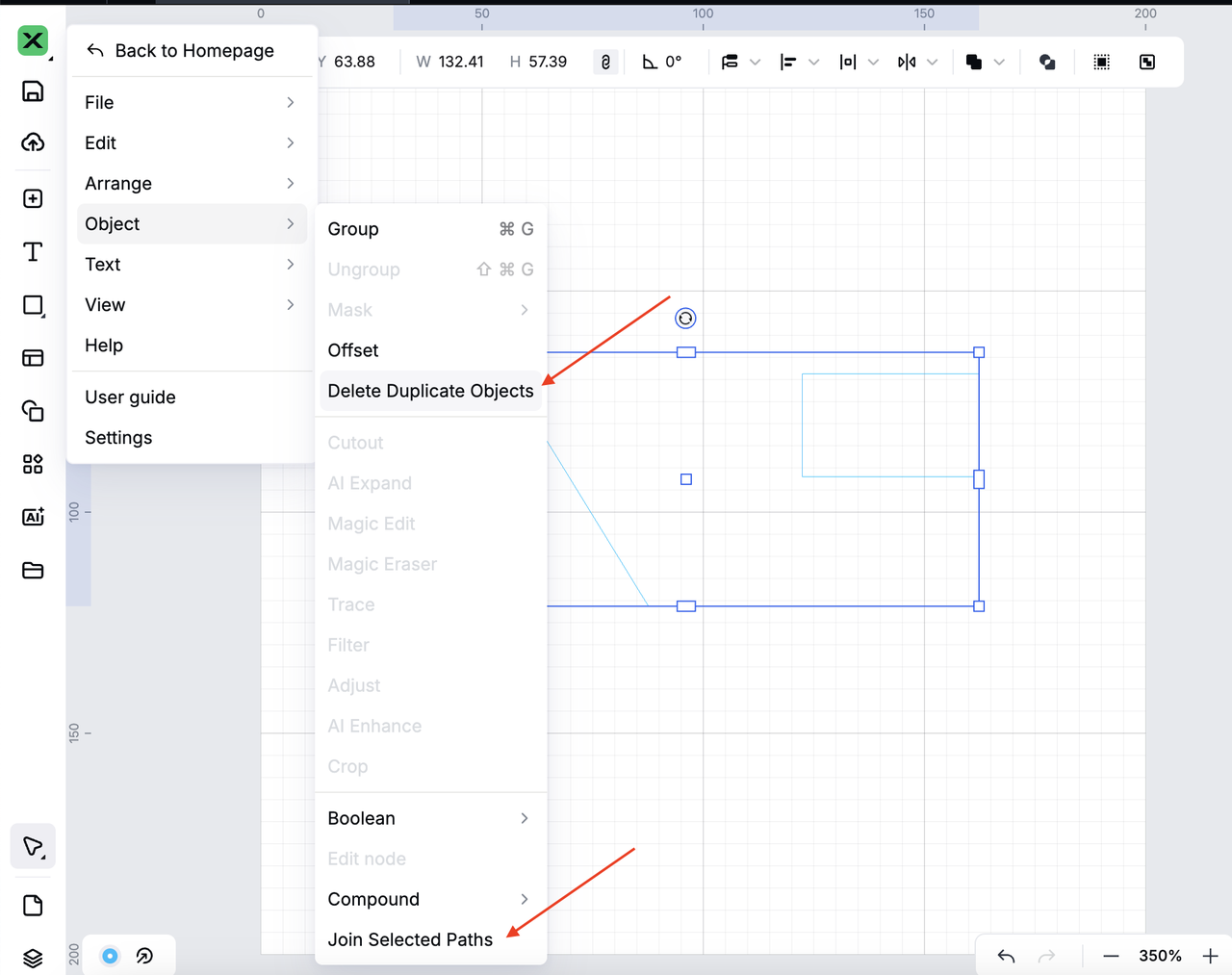

- Add “Join Paths” and “Remove Overlapping Objects” options under the Object menu

- Join Paths:

When open paths are selected, you can use Join Paths to connect them. Both connections within the same path and between different paths are supported. - Delete Duplicate Objects:

When specific objects are selected, duplicate detection will be performed among the selected objects. If no objects are selected, the system will check all objects on the canvas.

- Join Paths:

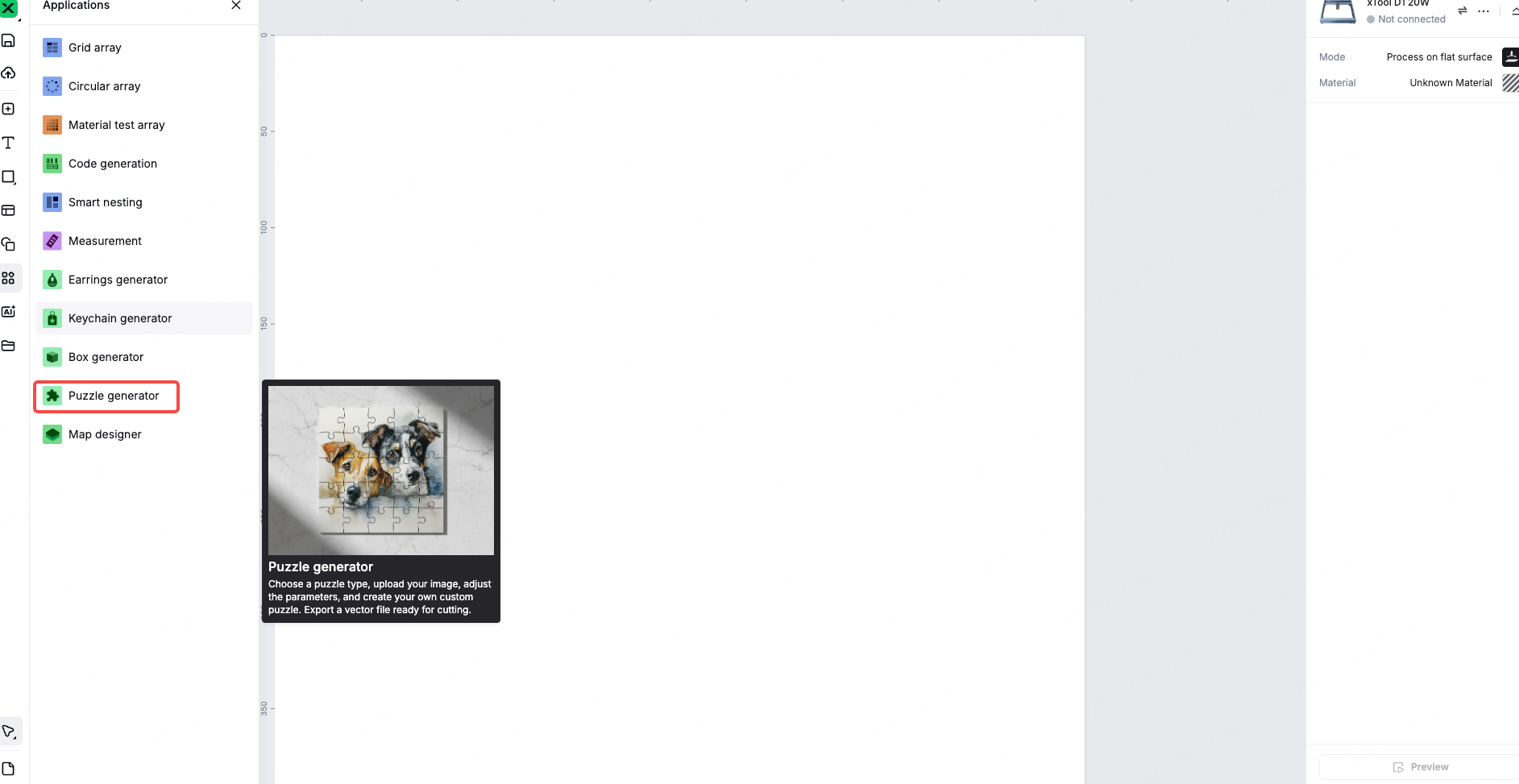

- Puzzle Generator: Added a Puzzle Generator that supports custom image uploads and quick parameter adjustment to create puzzles of various sizes and shapes.

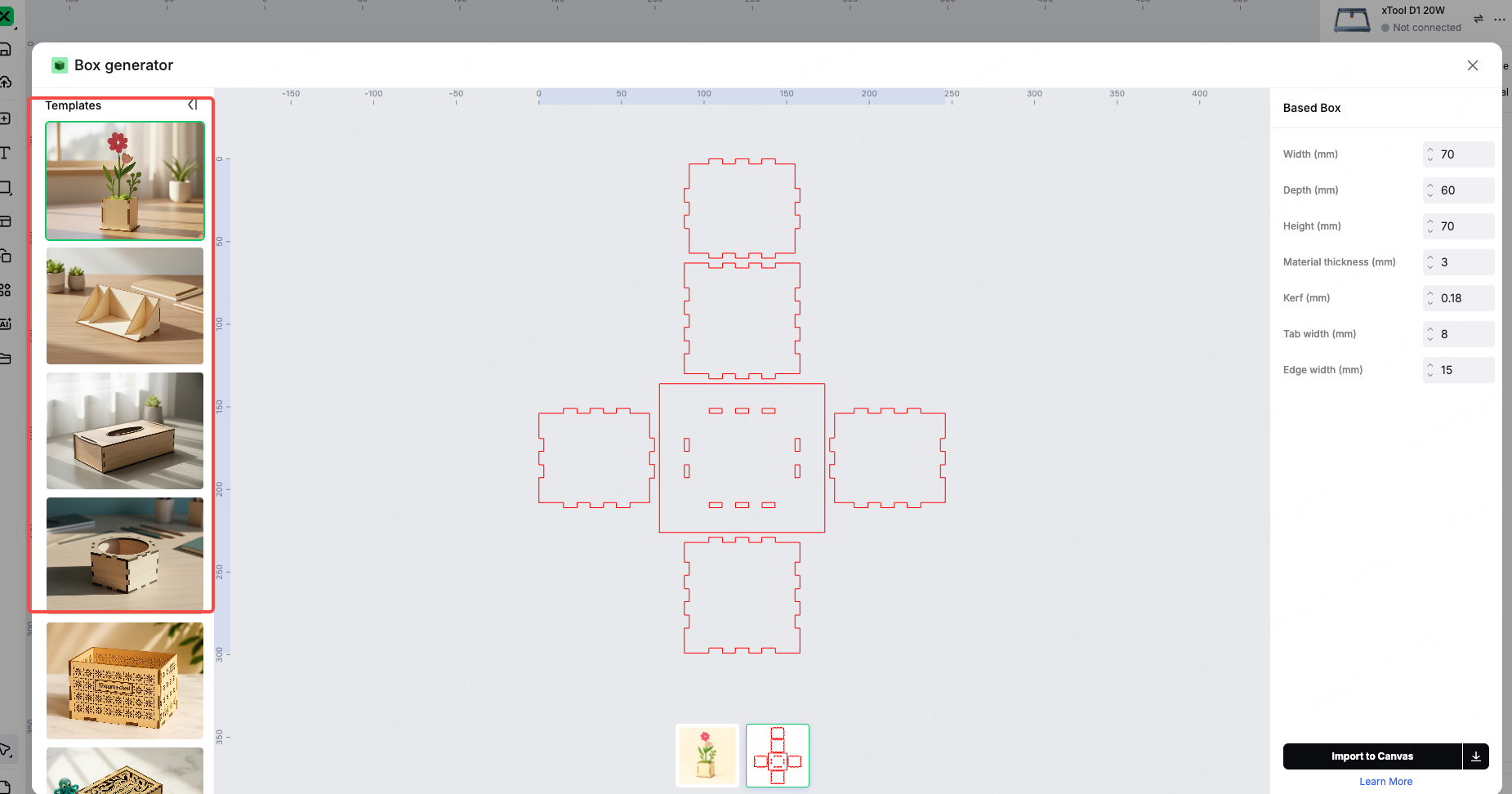

- Added 4 new parametric boxes in Box Generator: Basic Box, Triangular Box, Tissue Box, and Polygonal Box.

- Material Library Management Experience Optimization:

- A new "My Materials" tab has been added, making it easier to edit and manage the material parameters you've saved.

- Secondary material categories and multilingual support for material names have been introduced. Additionally, a built-in FAQ with processing tips is now available, making it more efficient to find and use materials.

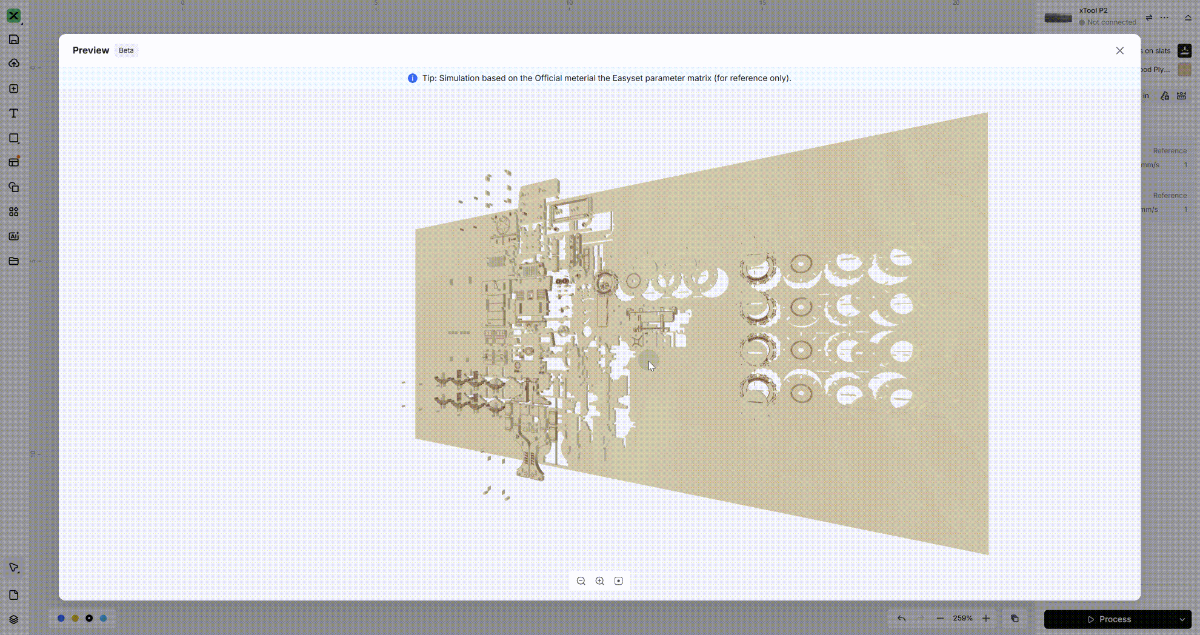

- Processing Preview Visual Optimization: The 3D scene is newly upgraded to create an immersive preview experience through point light animation, HDR configuration, and physics engine support.

- Optimized the device and accessory unbinding process: simply hover your mouse over an accessory to unbind it directly.

- Optimization of P3-related functions:

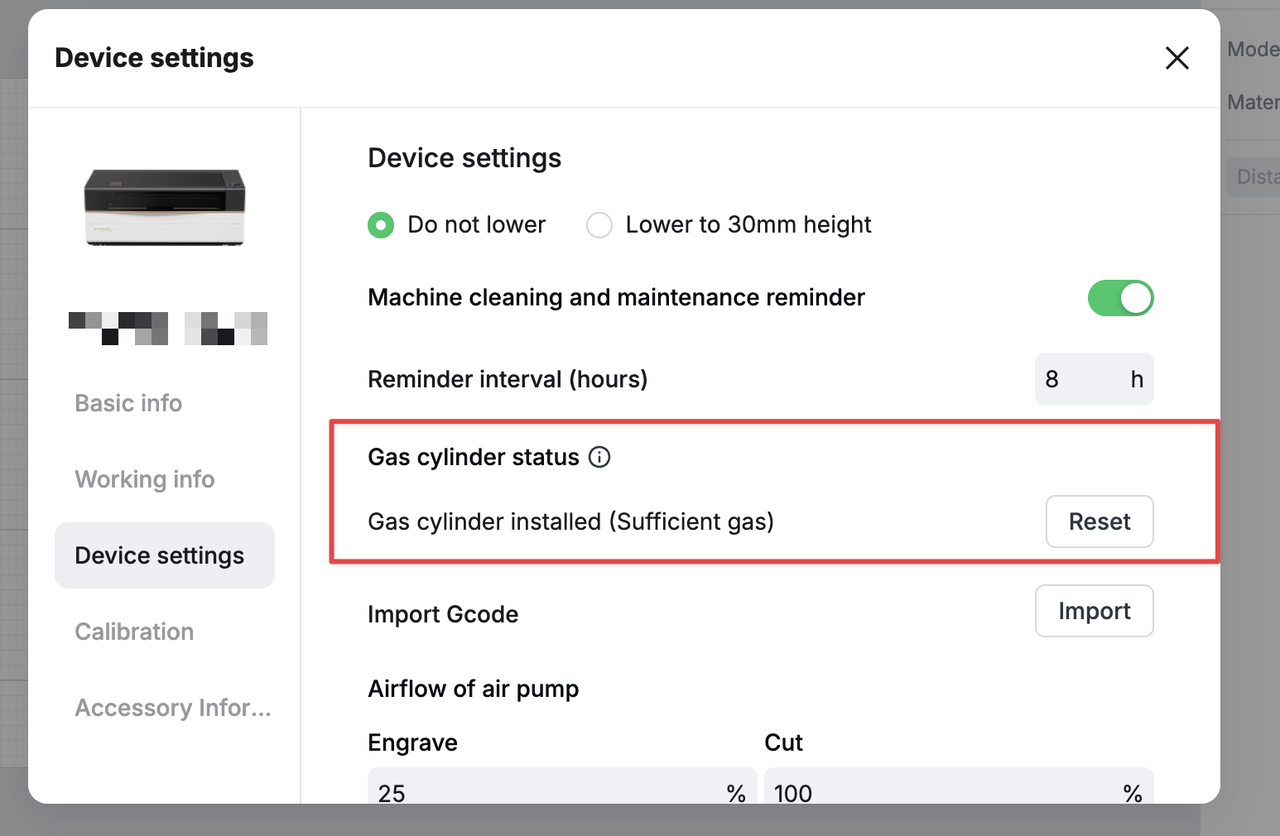

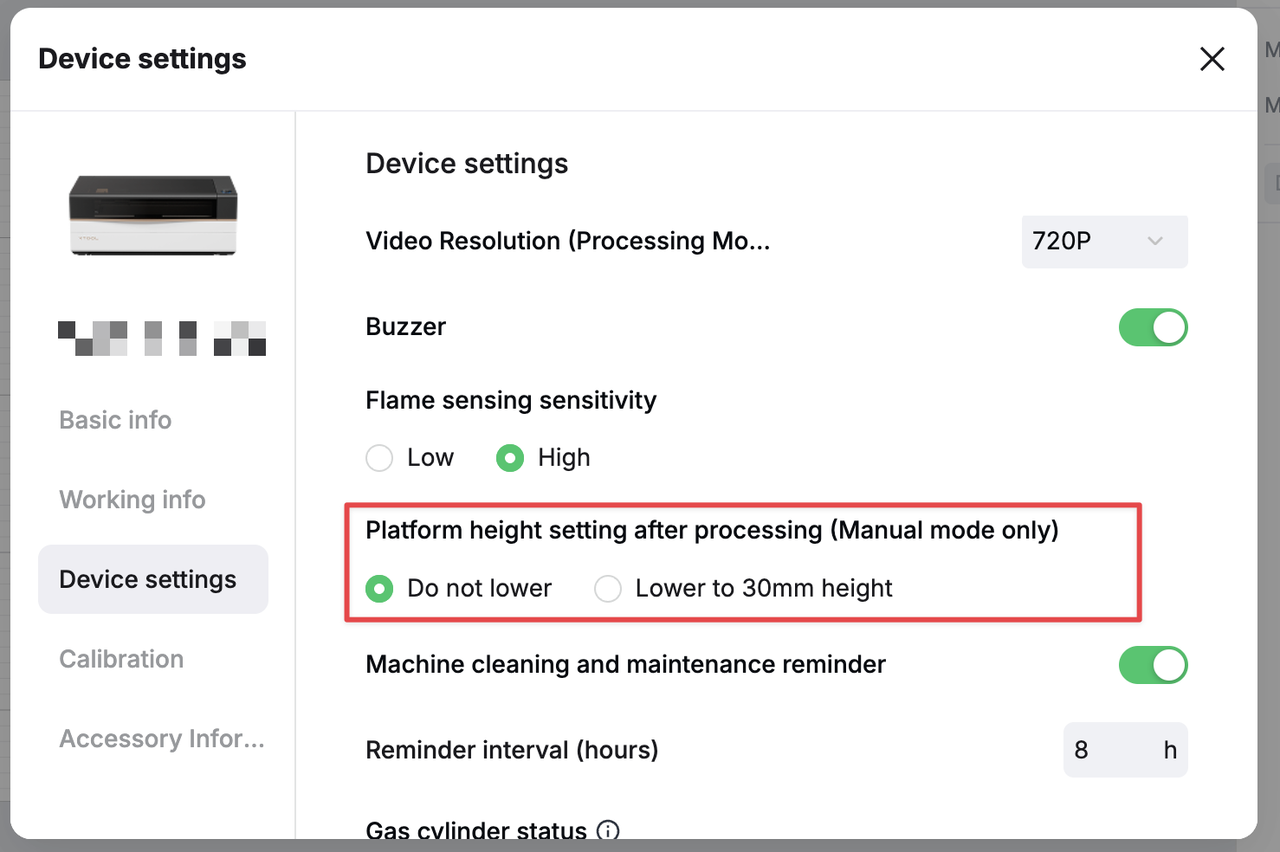

- Display cylinder status in device settings and support cylinder calibration.

- Optimize the issue where slow lid closing causes automation failure.

- Improve close-up stitching speed;

- Support keeping the laser module from lowering after processing in manual mode.

- MetalFab Bitmap Engraving Effect and Interaction Optimization

- Bitmap Engraving Effect Optimization: Optimized bitmap engraving effects, adding over-scanning and intelligent path algorithms.

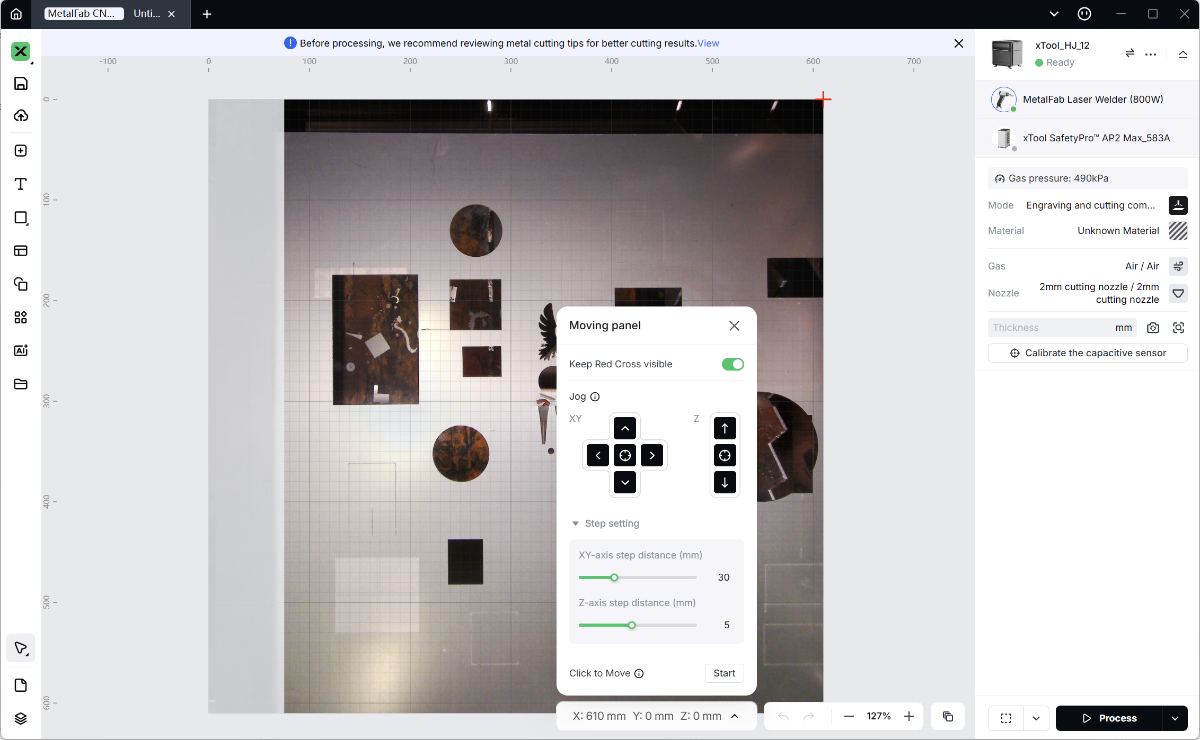

- New Laser Head Control Panel: Added a laser head control panel supporting quick laser head movement and jogging functions via shortcuts.

- Thick Material Parameters and Guidance: Unlocked parameters for some thicker materials and provides corresponding cutting guides.

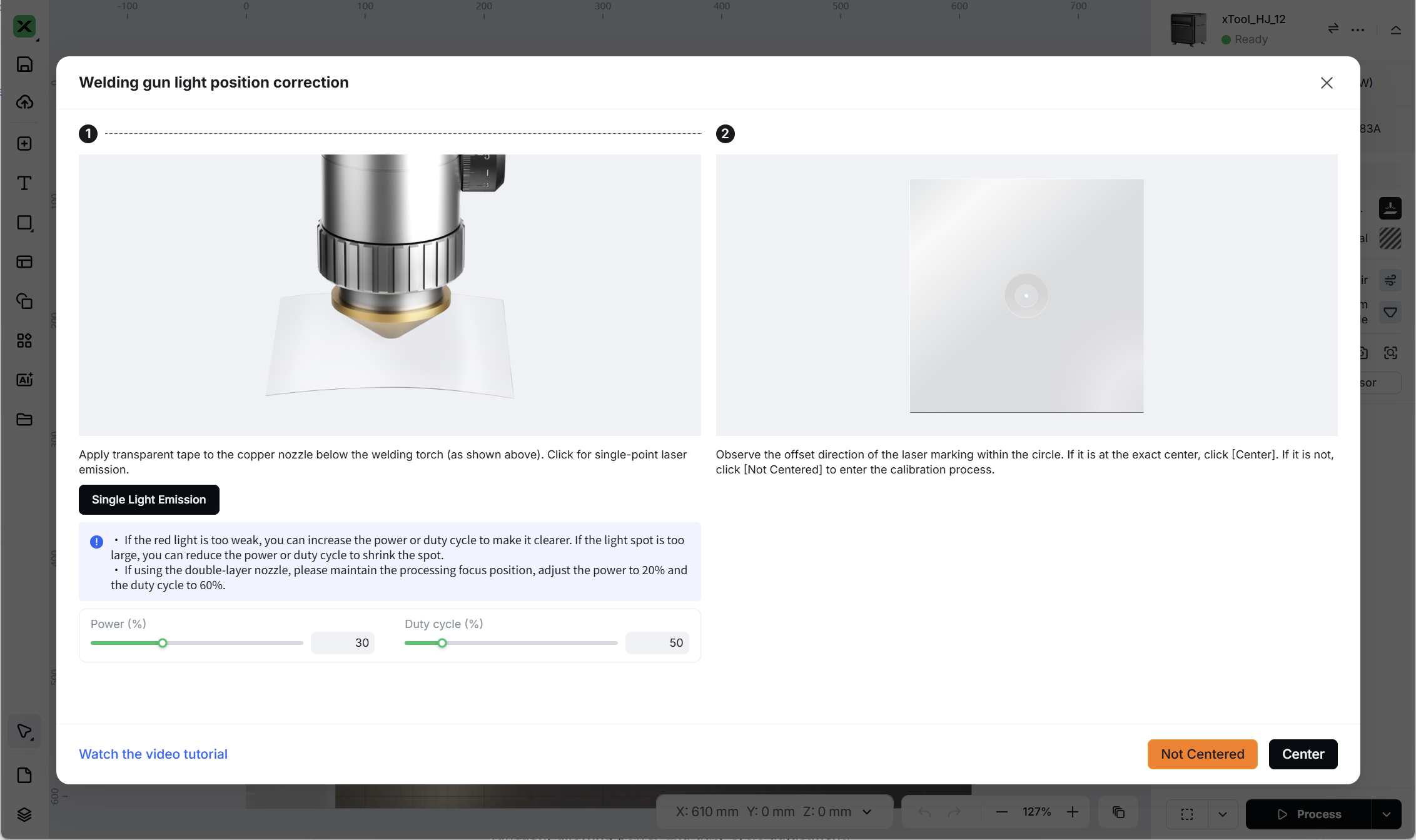

- Welding Torch Emission Position Correction: Optimized the welding torch emission position correction function, allowing power and duty cycle adjustment.

- Parameter Description Optimization: Optimized the comments for parameter descriptions.

- Fixed some bugs.

- Apparel Printer: Supports specifying areas to exclude from white ink reduction by setting spot color channels.

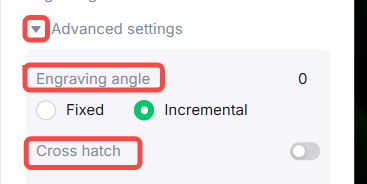

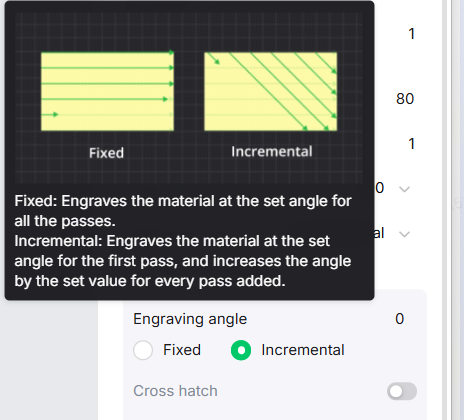

- F2/F2 Ultra/F2 Ultra(single) : In color engraving, you can enable the engraving angle and cross-hatch functions to create a vibrant color effect.

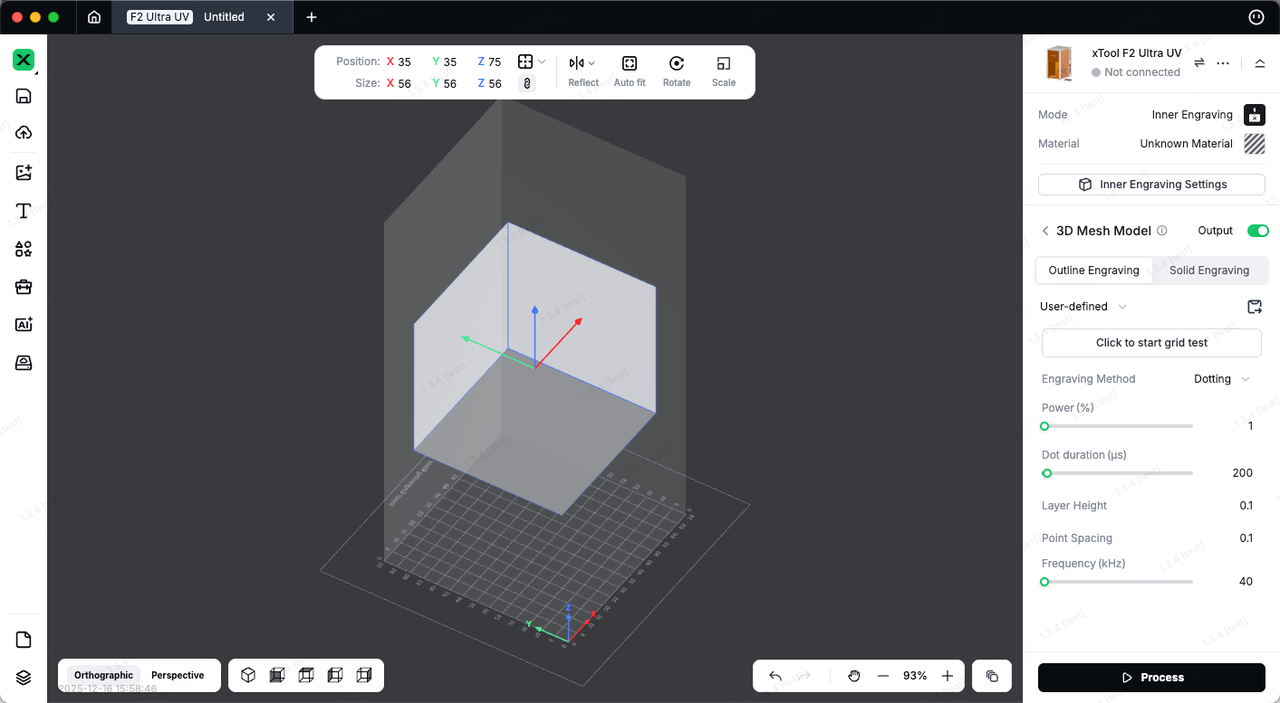

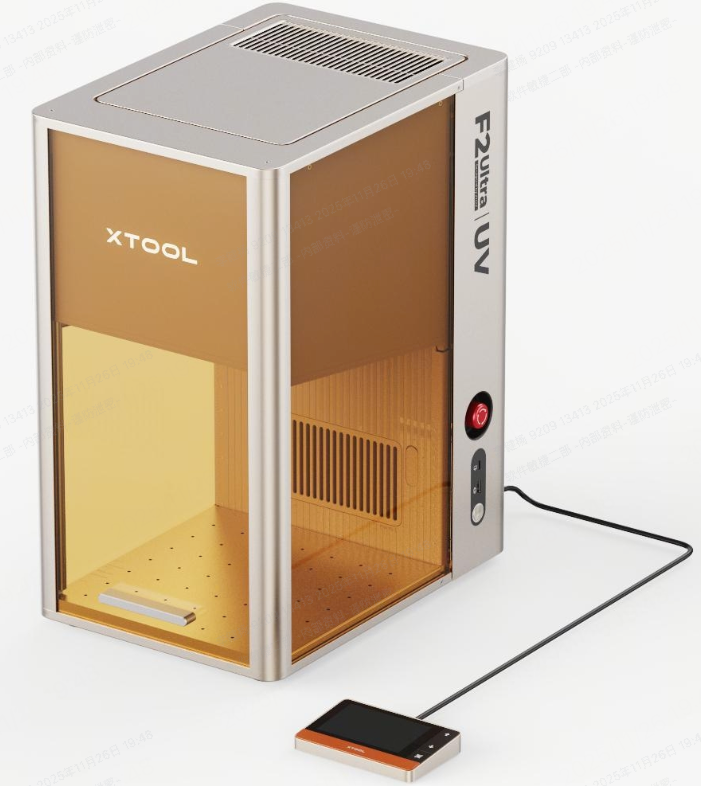

12. New Equipment Release: F2 Ultra UV

- More Materials: Unlock a wider range of materials for the most versatile laser: New engraving capabilities for transparent, heat-sensitive, and fragile materials such as glass, crystal, ceramics, textiles, and more. This expands the traditional laser processing range, allowing clear marking, embossing, and cutting effects on various materials.

- Glass Master: Glass internal engraving, embossing, cutting, and surface engraving: 3D/2.5D intelligent internal engraving enables the carving of 2D patterns or 3D models inside glass. On the glass surface, it can achieve various effects like embossing, cutting, and rotary engraving, meeting the demands for high-value, differentiated craftsmanship and diverse applications.

- UV Performance: High precision with cold processing and no burn edges: No burn edges or scorching, delivering clean, high-quality finished products that require no additional polishing. It provides a clean, high-quality result in one step.

xTool Studio Desktop V1.1.10 Release Notes

Version: Desktop V1.1.10

Date: October 21st, 2025

Update Notice (Windows Only)

To avoid having multiple desktop icons, this update will automatically uninstall previous versions of Studio during installation.

This will not affect your local or cloud data.

If a User Account Control (UAC) prompt appears asking to run “Uninstall xTool Studio.exe”, please allow the changes to continue the installation.

Introduction

- Support for incremental software updates, improving the update experience.

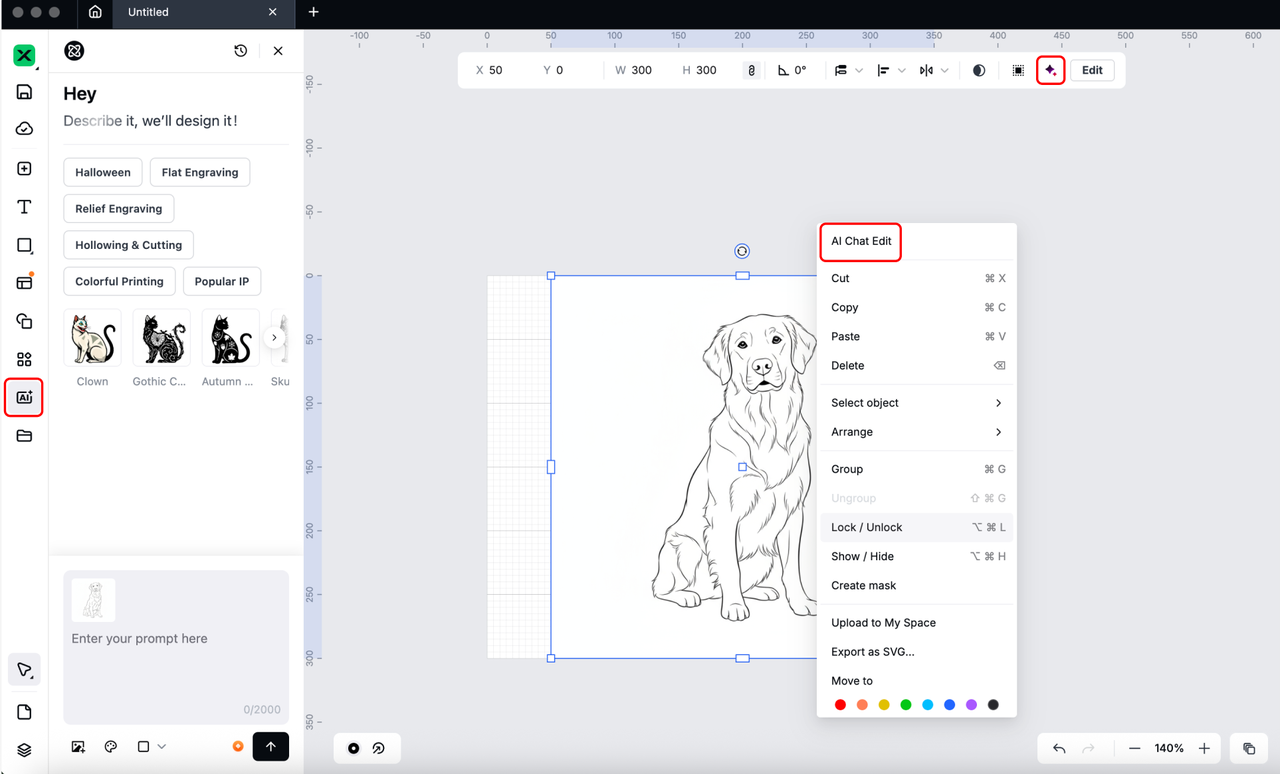

- New AImake experience: Users can now access the complete set of AImake features, achieving a seamless workflow from AI generation to actual processing.

- Sidebar: Click the AImake icon in the Studio sidebar to open the dialog panel. You can generate images with AImake and directly insert them into the canvas.

- Canvas:

- Click any bitmap image on the canvas to quickly open AImake via the top toolbar.

- Or right-click to select AI Chat Edit, using AImake to edit, optimize, or generate design variations through natural language input.

- Users can perform secondary creations based on existing designs, enabling a closed-loop workflow from AI generation → editing → printing/engraving.

- Optimized mask feature: Choose “Mask” or right-click on the image menu to “Create Mask.” You can select preset shapes or use vectors/paths on the canvas as masks.

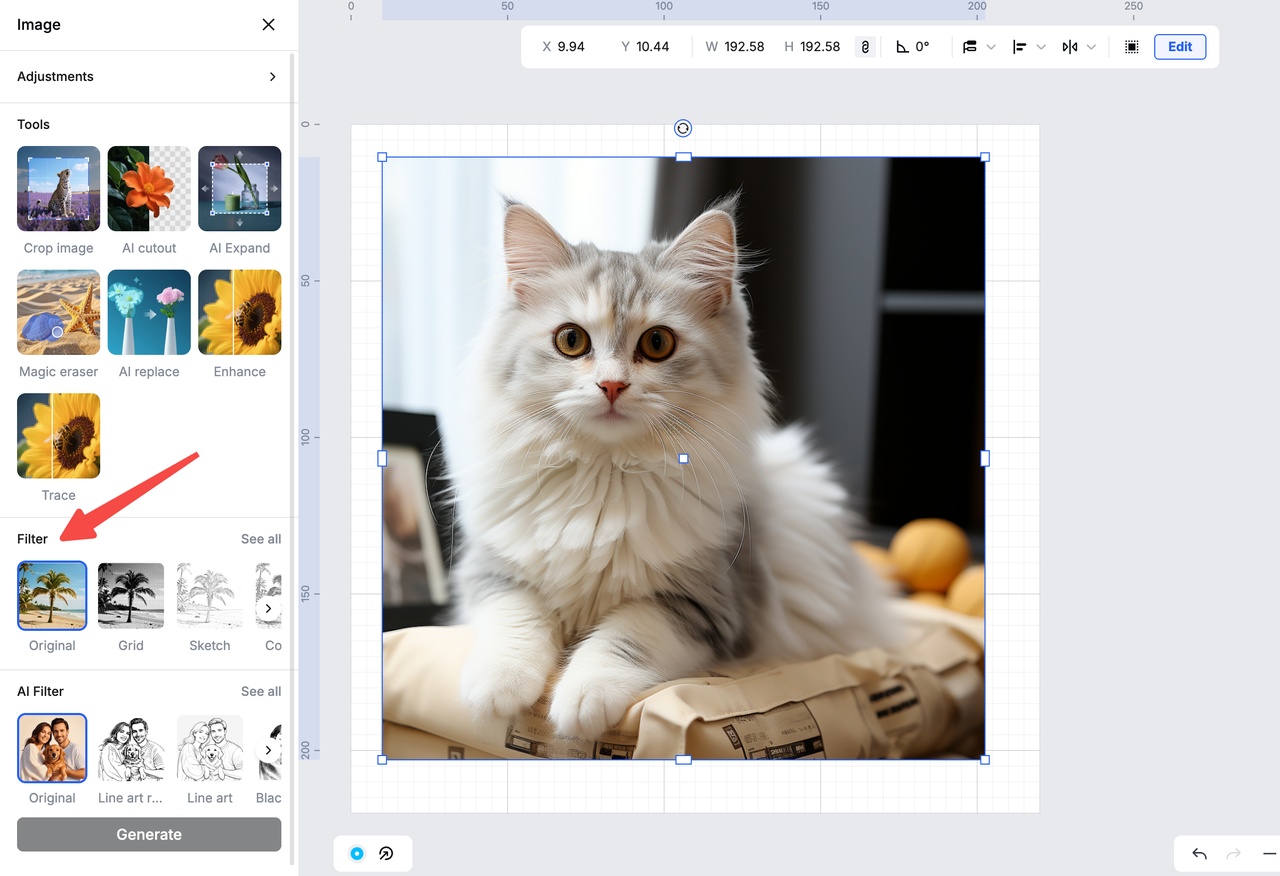

- Optimized image tracing: Improved preset parameters to reduce overlapping paths and added a fill preview.

- Optimized smart nesting: When elements cannot fit into the designated area, the system will automatically arrange them neatly.

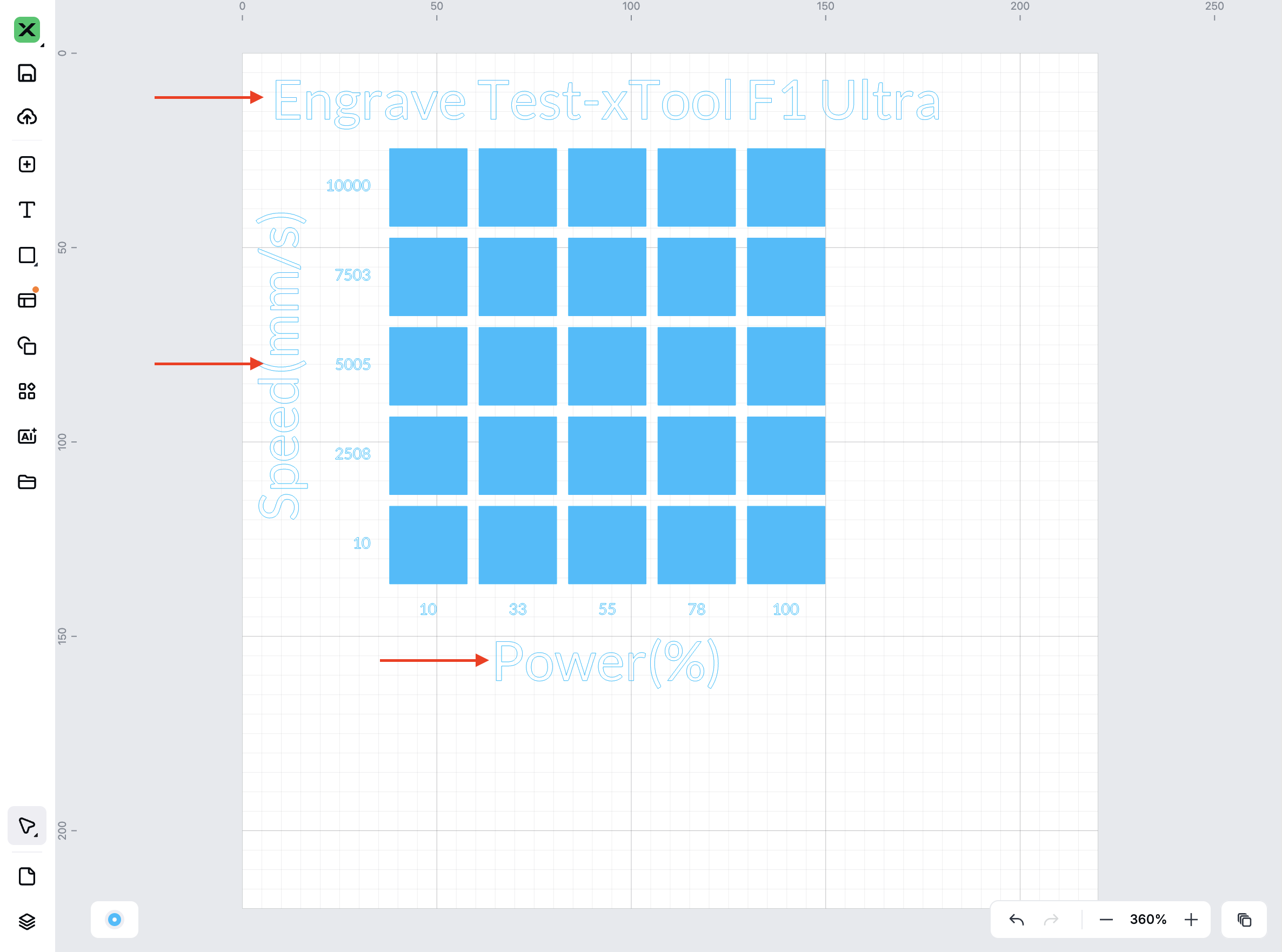

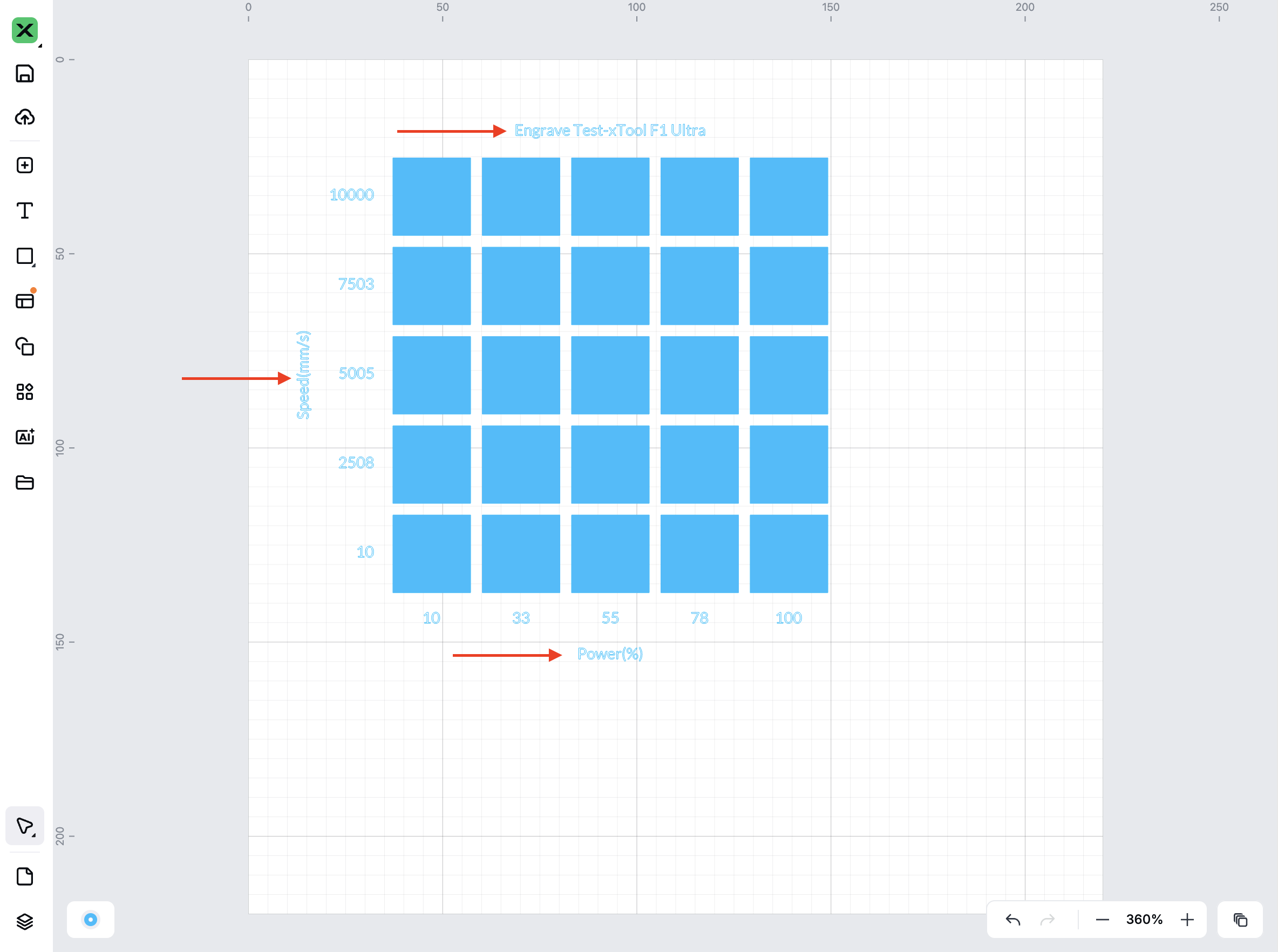

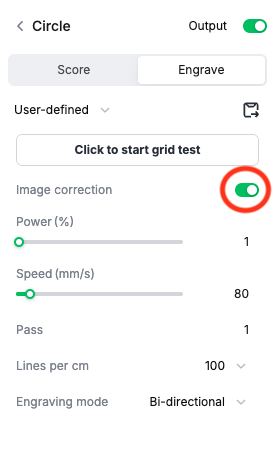

- Optimized material grid test:

- In "Process on flat surface" mode, users can select different material types to get recommended parameter ranges for grid testing. Historical grid test records are saved for direct reuse.

- Adjusted grid test text size: Reduced the text scale in generated grid tests to save material usage. Comparison before and after provided.

- In "Process on flat surface" mode, users can select different material types to get recommended parameter ranges for grid testing. Historical grid test records are saved for direct reuse.

- New connection error repair function, with one-click issue reporting support.

- Upgraded safety training: Streamlined training content and made it a required step (users who have already completed training are not affected).

- Support for customizing default processing mode: You can change the default processing mode in the mode selection window, and new files will automatically use the updated default mode.

- P3:

- In automation mode, quickly switch to manual mode.

- Support for batch filling in lift platform processing mode.

- Manual selection of distance-measuring points when close-up photography fails.

- Improved nesting performance for non-reflective materials.

- In automation mode, quickly switch to manual mode.

- MetalFab:

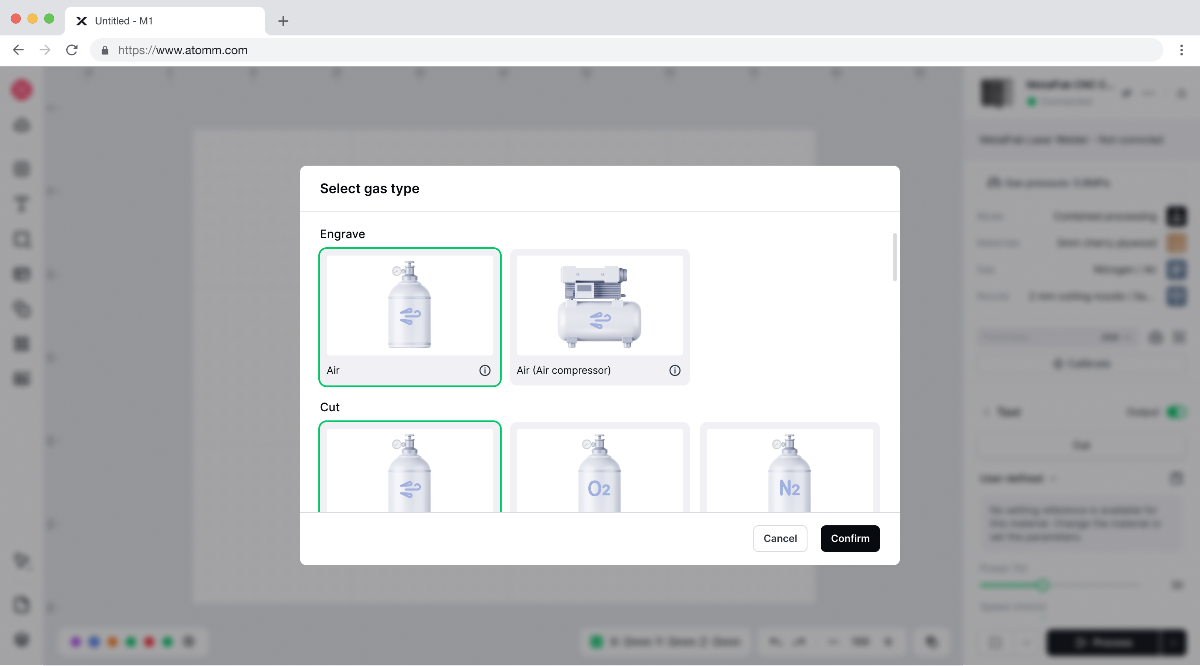

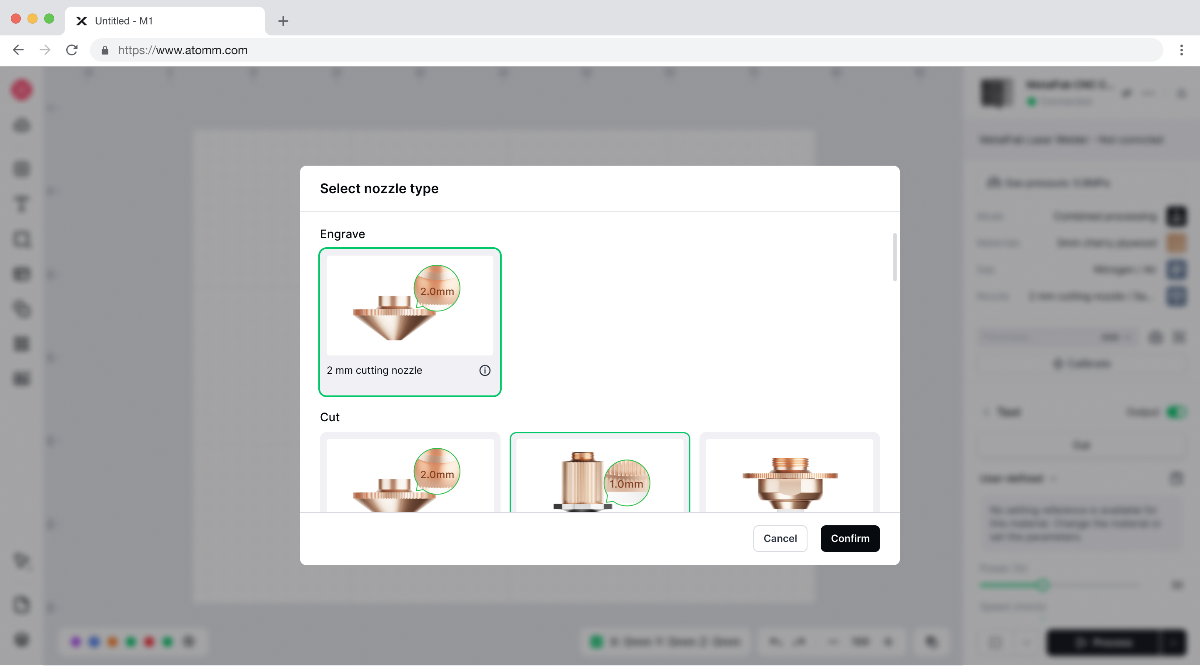

- Added gas and nozzle configuration: Selecting gas and nozzle will auto-configure recommended parameters based on hardware, along with suggested air pressure and focal length for different materials.

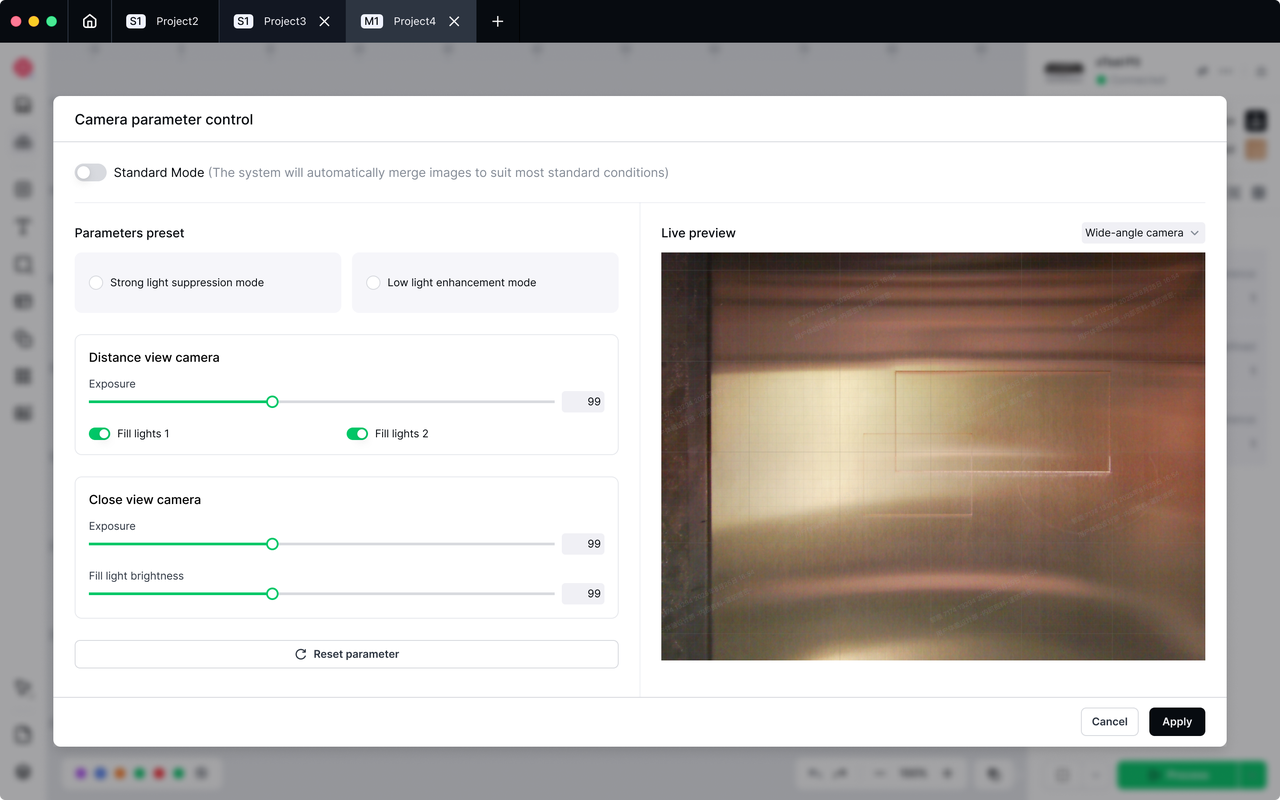

- Added Manual camera mode: Adjust camera settings manually for special scenarios, such as suppressing overexposure under strong outdoor light.

- Added Manual camera mode: Adjust camera settings manually for special scenarios, such as suppressing overexposure under strong outdoor light.

- Added gas and nozzle configuration: Selecting gas and nozzle will auto-configure recommended parameters based on hardware, along with suggested air pressure and focal length for different materials.

- Added fixture collision prevention: The system automatically detects fixture areas to prevent head collisions.

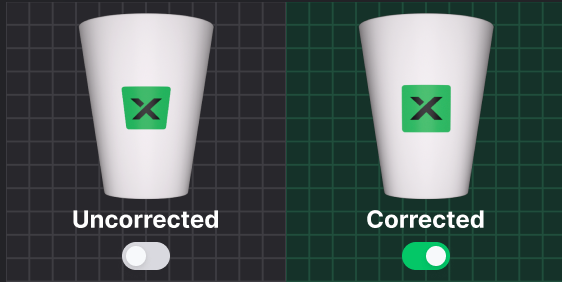

- RA3:

- Cylindrical settings: In manual mode, directly input parameters of rotating bodies to skip modeling steps for correction.

- Image correction: Optimizes visuals by calculating truncated cone and cylinder parameters.

- Rotational guides: Shows angle positions for each line when processing cups.

- Cylindrical settings: In manual mode, directly input parameters of rotating bodies to skip modeling steps for correction.

- AP2 Max: Optimized airflow strategies for different materials, reducing noise and extending filter life.

xTool Studio Desktop V1.0.15 Release Notes

Version: Desktop V1.0.15

Date: September 16th, 2025

Introduction

Fixed some known bugs.

xTool Studio Desktop V1.0.14 Release Notes

Version: Desktop V1.0.14

Date: September 4th, 2025

Notice on Transition from XCS to Studio:

- Studio is the upgraded successor to XCS (xTool Creative Space), offering enhanced UI, interactions, features, and richer design resources.

- The final release of XCS was V2.7. No further updates will be provided for XCS on PC or mobile; future updates will continue on Studio.

- XCS and Studio are independent applications and can be installed separately without overwriting each other.

- Starting with P3, all new products launched after August 2025 will be supported exclusively in Studio.

Introduction

For more details, see: https://support.xtool.com/article/2442

- All-new xTool Studio Client: A refreshed client with a smoother experience — now you can seamlessly connect your device and go from design to production with ease.

- More Creative Resources: Unlock a massive collection of fonts and design assets, plus the ability to upload your own. Available fonts increased to 1,800+, and available assets increased to 7,000+.

- Canvas: Canvas now supports a dark background.

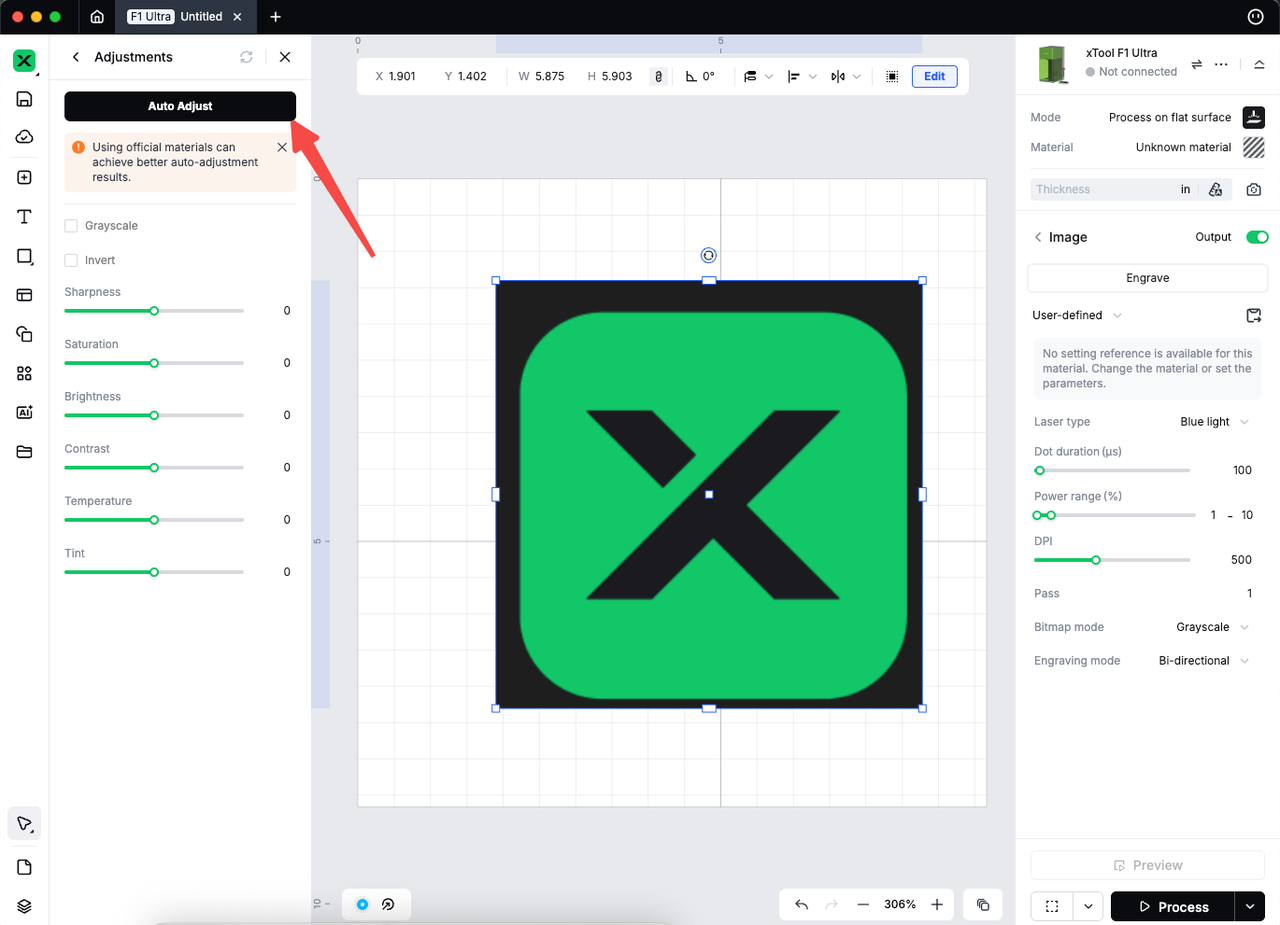

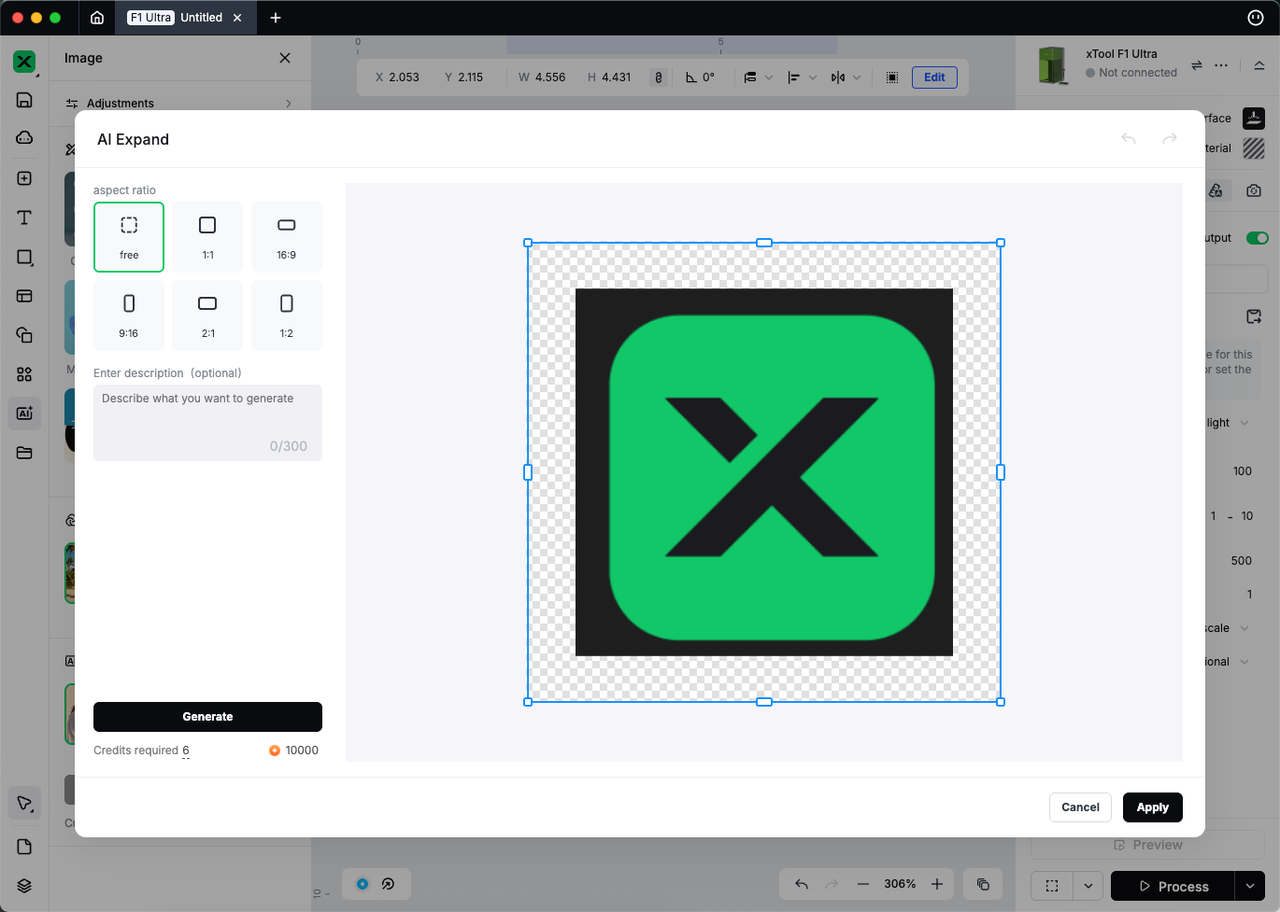

- Smarter Image Processing: Auto-adjust your images in one click, enjoy upgraded filters, and explore 3 new AI-powered tools for stunning results.

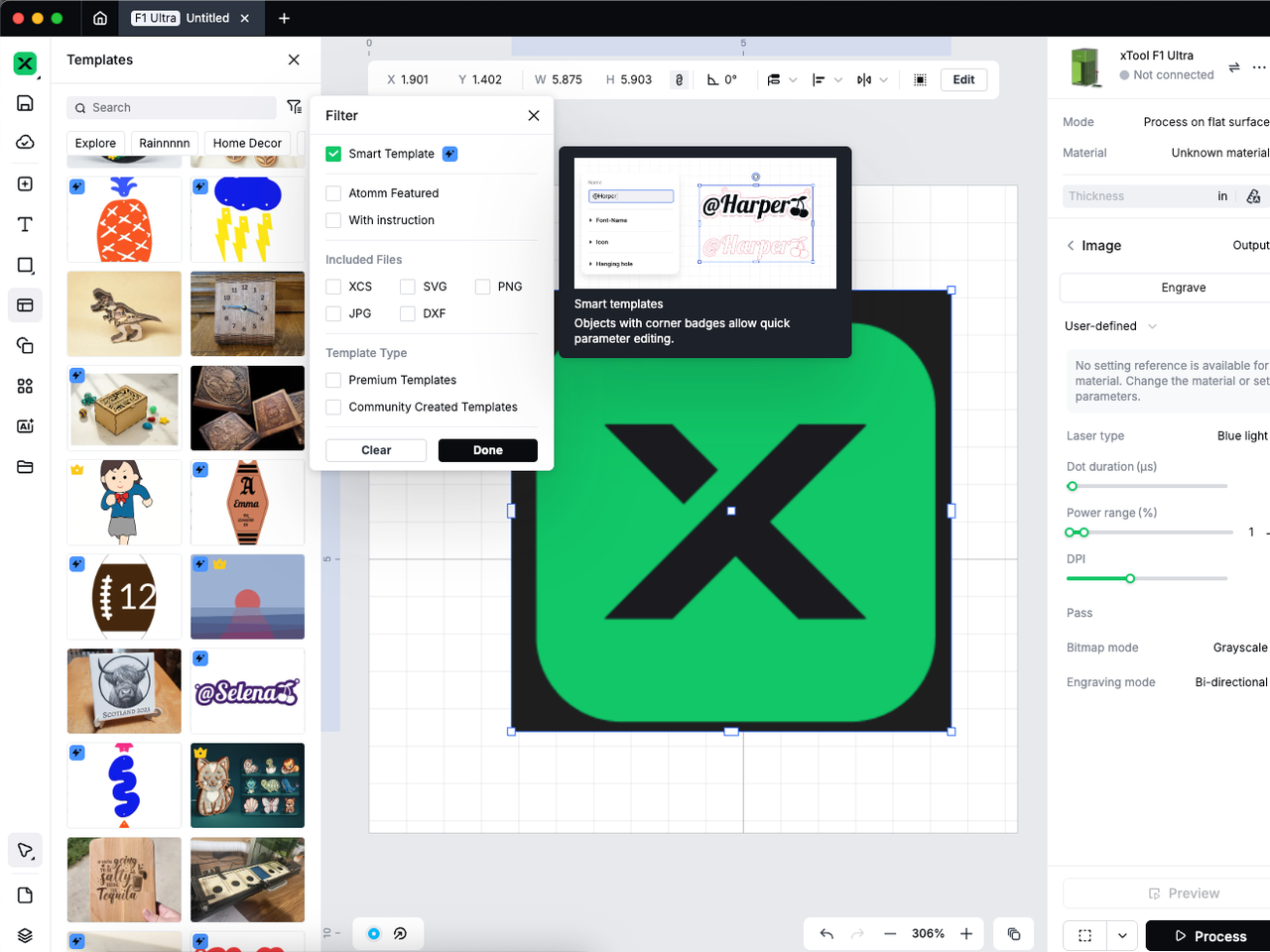

- Productivity Boosters: Speed up your workflow with smart templates and the new project generator that instantly creates ready-to-produce files.

- AI Tools: Enhance your images with AI—just select, edit, and shine.

- Enhanced Material Library: A redesigned material experience with detailed properties and usage tips, so you always choose with confidence.

- Cloud-Synced Parameters: Save and sync your parameter presets across devices, now with material-linked associations: https://support.xtool.com/article/2344

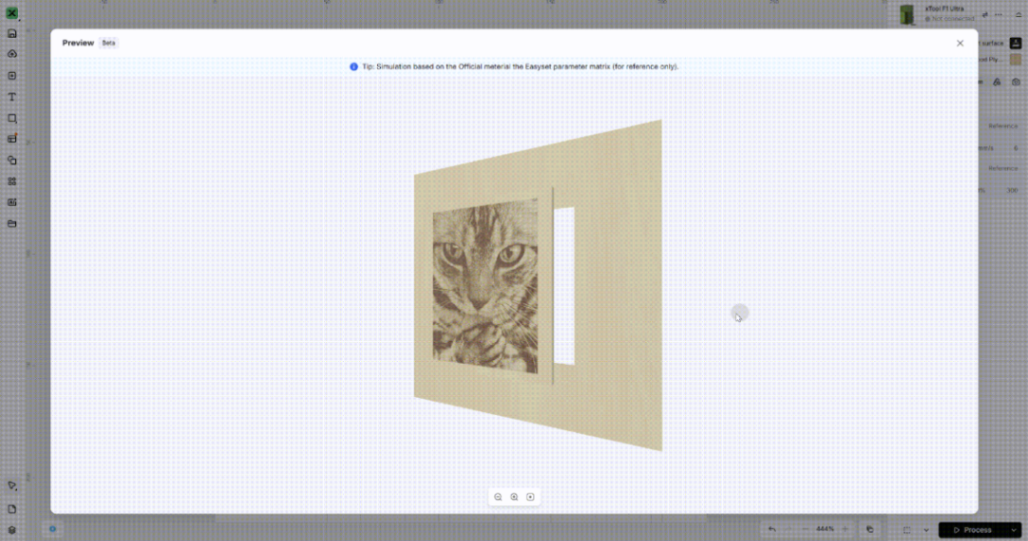

- Processing Preview: Simulate processing results before you hit “go” and let intelligent detection keep your output reliable.

xTool Creative Space Desktop V2.7 Release Notes

Version: Desktop V2.7.22

Date: June 19, 2025

- Added support for official consumables QR code recognition

- Introduced the AI Assistant feature

- Optimized certain features for the xTool MetalFab CNC Cutter、xTool Apparel Printer

- Enhanced user experience with the M1 Ultra Electrostatic mat

- Fixed some known bugs

xTool Creative Space Desktop V2.6 Release Notes

Version: Desktop V2.6.38

Date: April 18th, 2025

- Support xTool MetalFab CNC Cutter & Apparel Printer

- Map Designer is available in "Applications". You can use it to generate exquisite map design files.

- Copy-Paste Optimization:

- Paste across canvases/projects retains original coordinates.

- Subsequent pastes offset diagonally to the bottom right.

- Paste across canvases/projects retains original coordinates.

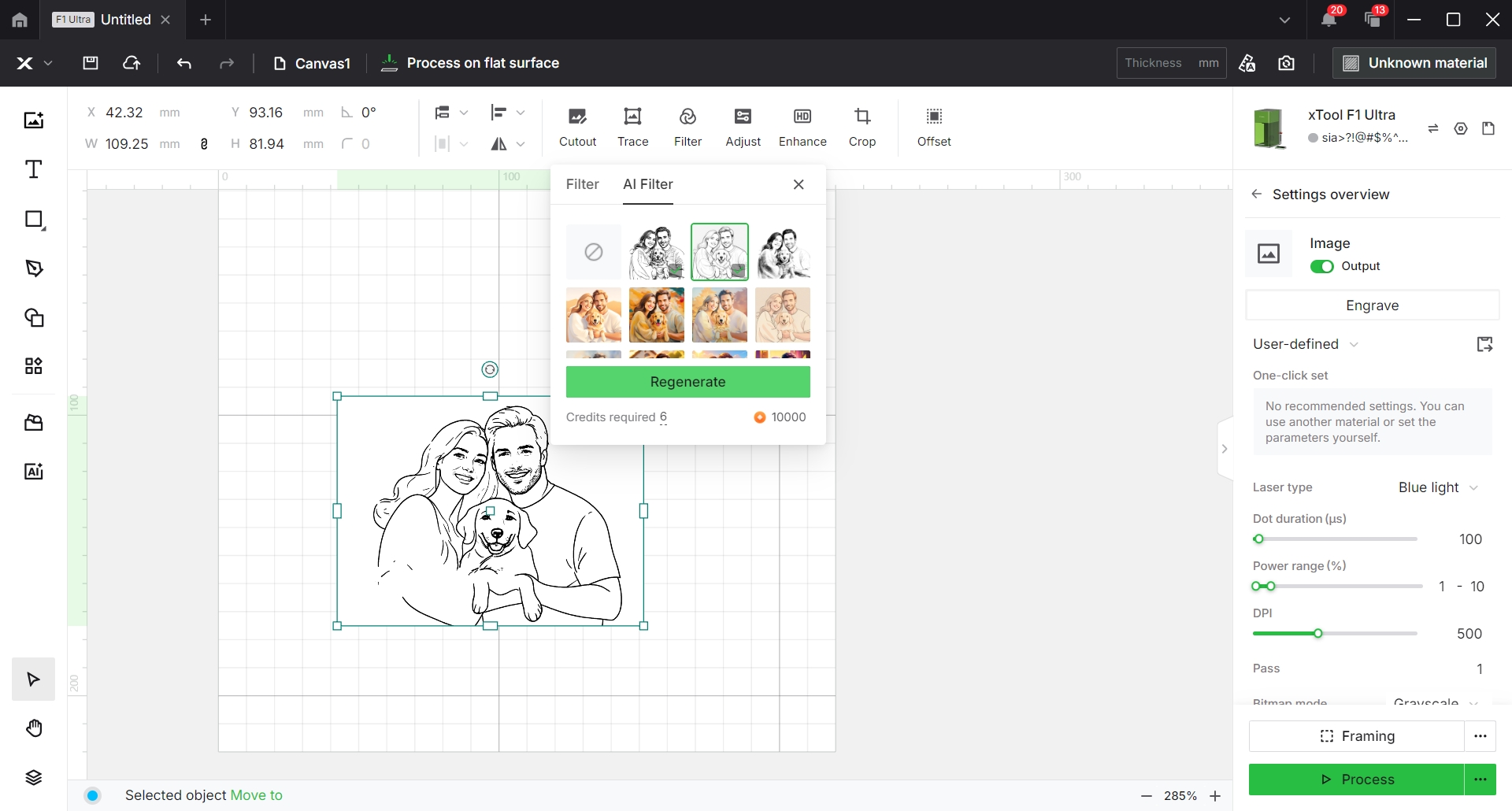

- Optimized AI filters.

- A new “Templates” entry has been added. Select a template, apply it with one click, and freely customize it to boost your efficiency.

- New "AI Cutout" feature added. Upload an image, automatically recognize the subject, click once to remove the background.

- Improved manual cutout: The manual cutout feature adds a "Continuous" option, allowing you to control whether the color removal applies to the entire image.

- Add “xTool Academy” to XCS sidebar.

- Fixed known bugs.

xTool Creative Space Desktop V2.5 Release Notes

Version: Desktop V2.5

Date: March 12th, 2025

Added

-Add Fire Detection to M1. You are able to enable or disable this function through the device settings.

-Add prompts and guidance regarding the placement of the rotary attachment and the mirror direction of design elements to the preview interface when using rotary attachment. Now you can confirm whether you have used the rotary attachment correctly and efficiently.

Optimized

-Optimize device connection:

- Add a reconnect function when encountering a connection failure.

- Fix the known connection failure issues.

-Optimize parameter settings of M1 Ultra:

- When the materials supporting the fine-point blade are selected in the blade cut mode, add a "Max Reference" option in the blade cut parameter settings.

- Optimize the parameter settings when using hot foil pen processing modules of different tip types.

- Fix some known issues.

xTool Creative Space Desktop V2.4 Release Notes

Version: Desktop V2.4

Date: January 15th, 2025

Added

-Add new example project tutorial: New example project tutorial is added when connecting to F1/F1 Ultra/P2S/S1 devices for the first time. Through step-by-step instructions, a case will be completed to help you understand the device more quickly. If the device is not connected for the first time, users can trigger the example project tutorial again next to the device settings on the right.

-Add guide lines: Support using guide lines in the canvas. Drag and drop in the horizontal/vertical direction of the canvas ruler to add them.

-Add new measurement tool: Support measuring the distance between two points.

|

|

-P2 introduces a new processing mode, referred to as Curved Material - Use Rotary Attachment. This mode is an upgrade based on Curved material mode, allowing users to perform carving operations on more complex rotational surface objects, thereby better addressing user requirements.

-Add text uppercase function: Support quickly converting English text to all uppercase format to facilitate format unification or meet specific text editing requirements.

-Add Split text function: Support splitting the text in the text box into separate text boxes, and each character can be edited and operated individually.

-Add Convert to path function: Support converting text characters into vector paths. After conversion, the path nodes can be edited. This function is suitable for occasions where complex image editing or creative design of text is required, allowing the text to be freely deformed and adjusted like an image.

-Text dynamic welding function: Support identifying and merging overlapping parts between texts. After welding, text editing is still supported. This function is suitable for scenarios where multiple text elements need to be combined into one whole.

Optimized

-Optimize the hints for processing parameter function descriptions: A new display form of pictures and texts or GIF + text is added to help you better understand the application of this function.

-Optimize device connection:

- Add network configuration guidance when a new device is connected.

- Increase the speed of searching for WIFI.

- Support automatic reconnection of devices through different connection methods.

- Fix the known connection failure issues.

-Optimize canvas grid settings of the XCS editor:

- Support adjusting grid view values: Dark, Medium, and Light. It can be set in the XCS main menu - View.

- Support showing/hiding grid: It can be set through the main menu or right-click.

|

|

-Optimize the offset function: Support generating inner and outer offset simultaneously. The corner style of the offset can be set.

-Optimize the layout of newly added objects: By default, they are displayed in the center of the view window.

-Optimize the cloud storage function:

- Support manually uploading files to "My Space" within the canvas.

- Files uploaded to "My Space" will automatically save changes to the Cloud when edited.

|

|

-Optimize AImake layout: To make it easier for users to use AImake, we integrated AImake into the left sidebar of the canvas. Users can select style, input description, generate AI images, and import them into the canvas.

-Optimize Align center rule: When objects are selected in sequence, they will be aligned to the center of the last selected object.

xTool Creative Space Desktop V2.3 Release Notes

Version: Desktop V2.3

Date: November 25th, 2024

Added

-Added Different design – batch processing mode for xTool F1 Ultra. In this mode, you can set variables for a batch of designs, enabling batch changes to elements like text, images, and vectors, and process the designs in groups on the material.

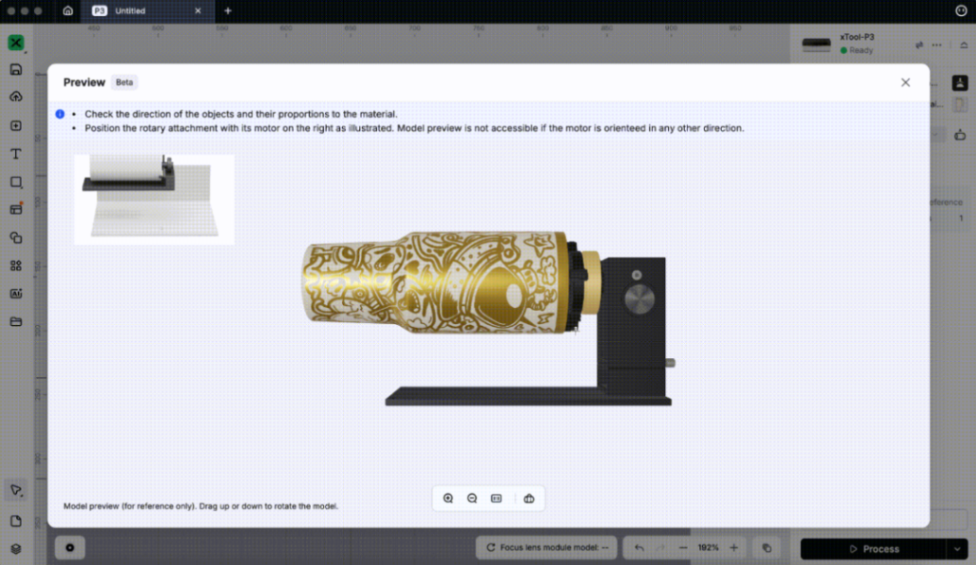

-Added the model preview feature for the Use rotary attachment mode. By generating models based on input data and objects on the canvas, this feature allows you to check the orientation of the objects and their proportions to the materials. The rotation direction of the models is consistent with the processing direction of the device.

Optimized

-Optimized the Chuck – Use rotary attachment mode for xTool P2, P2S, M1, and F1 Ultra. This version supports processing in grey-out areas, and center positioning of objects and processing based on the central axis.

-Optimized the Chuck – Use rotary attachment mode for xTool M1 Ultra and S1. After the laser module's red cross is moved to the highest position of the cylinder and distance measurement is done, XCS will auto-generate a cylinder axis based on the position of the red cross. This helps facilitate the positioning of objects on the canvas.

-Increased the diameter upper limit in Chuck – Use rotary attachment mode, allowing processing objects with a diameter no greater than 120 mm and a processing area exceeding 120 mm.

-Increased the upper limit of parameter schemes per processing type from 30 to 100, and introduced scheme management. With scheme management, you can search, rename, import, and export parameter schemes, and associate them with devices (schemes show only for the associated devices). Additionally, parameter schemes can be synchronized to cloud for access across multiple devices using the same account.

-Optimized the undo and redo functions. You can now undo and redo more actions, such as modifying processing parameters, types, and modes, adding and deleting canvas, and so on. Additionally, you can precisely identify objects affected by these actions.

Getting Help:

- If you encounter any problems, please contact support@xtool.com

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.